Nanobubble hydrogen water producing machine

A hydrogen-producing water machine and nano-bubble technology, applied in the direction of adding substances to water/sewage treatment, etc., can solve the problems of electrode metal ion shedding, changing the acidity and alkalinity of the soaking solution, and affecting the purity of water, etc., to achieve strong oxidation resistance, Ease of oxidation-reduction potential and effect of improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

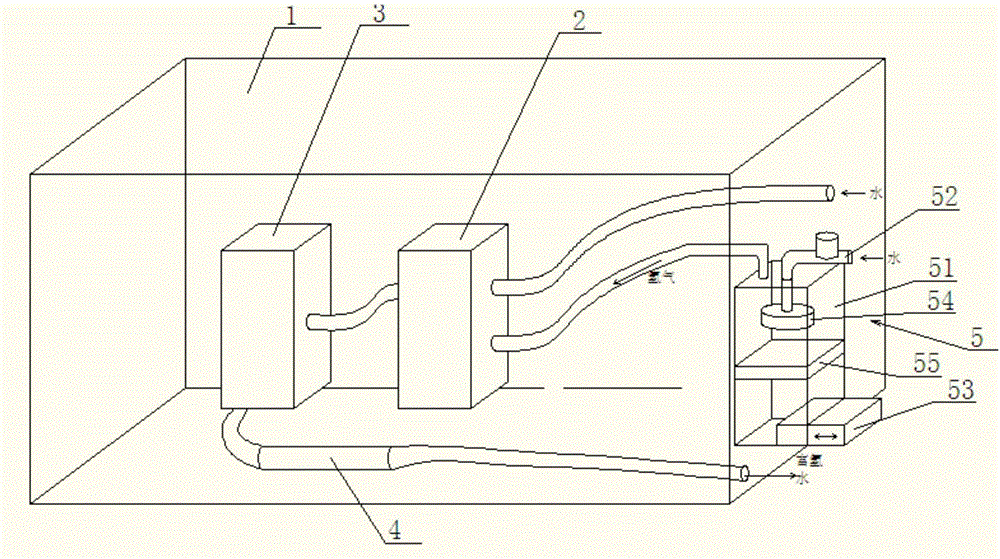

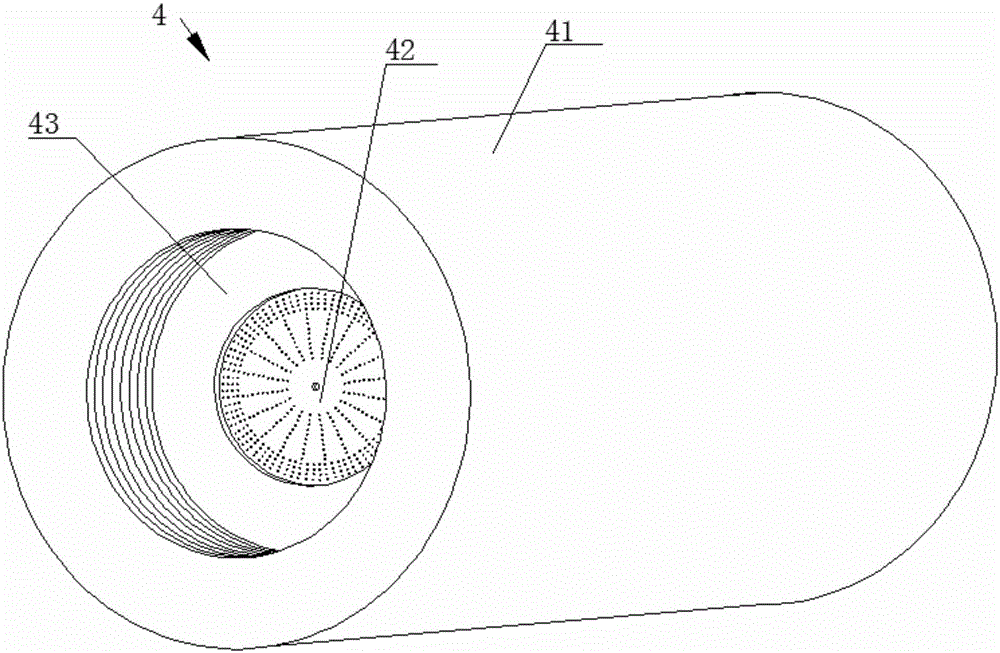

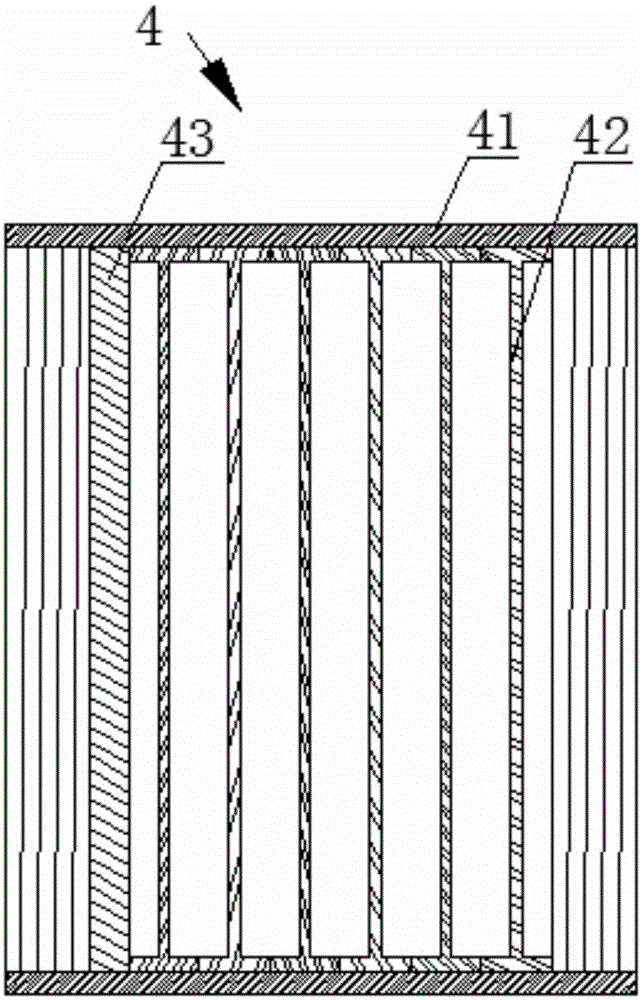

[0021] Such as figure 1 As shown, the nano-bubble hydrogen-producing water machine includes a box body 1, a hydrogen supply pipe, a water supply pipe, a pressure pump 2, an air-dissolving tank 3, a nano-hydrogen bubble generator 4, a bubble water pipe, and a hydrogen generator 5. One end of the hydrogen supply pipe and the water supply pipe are installed on the box body 1, and the other ends of the two are respectively connected with the air inlet and the water inlet of the pressure pump 2, between the inlet of the dissolved gas tank 3 and the outlet of the pressure pump 2 Water pipe connection, also adopt water pipe connection between the outlet of dissolving gas tank 3 and the inlet of nanometer hydrogen bubble generator 4, bubble water pipe is connected on the outlet of nanometer hydrogen bubble generator 4. The hydrogen generator 5 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com