Feeder flow automatic control method in tobacco primary processing line

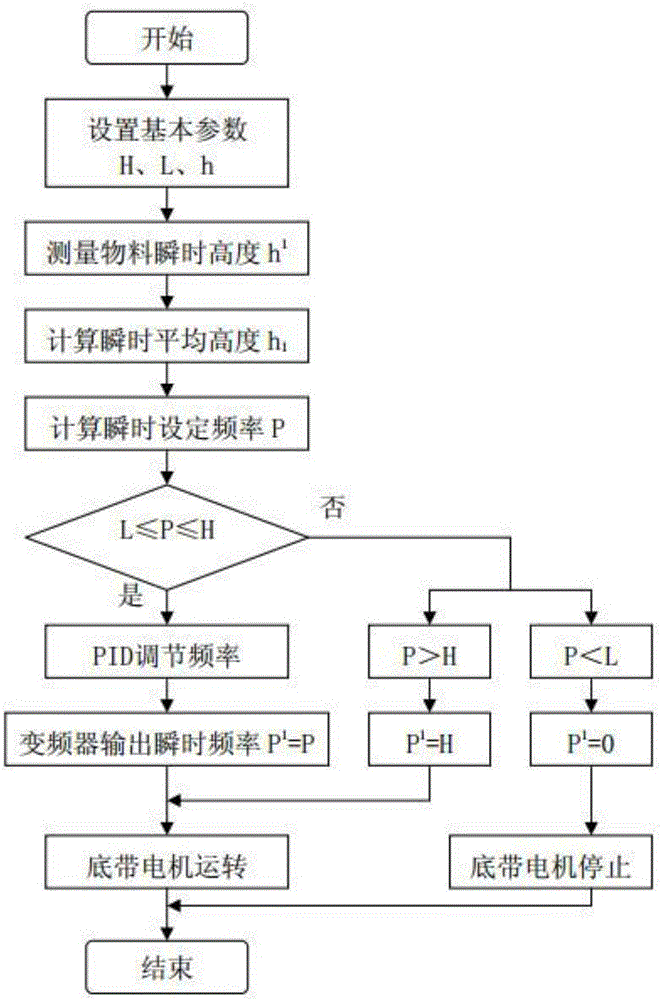

A feeder and production line technology, applied in conveyor control devices, conveyor objects, transportation and packaging, etc., can solve problems affecting tobacco silk production efficiency and product quality, frequent start and stop of the bottom belt of the feeder, and material height. Uneven laying and other problems, to achieve the effect of simple mechanism, avoiding uneven accumulation and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] According to the equipment control capability and process requirements, in this embodiment, the upper limit frequency H of the bottom belt motor is set to 50HZ, the lower limit frequency L is 30HZ, and the material standard height value h is 30CM.

[0029] After the production starts, the lifting belt runs, requiring the feeder to enter the discharging state. At this time, the laser ranging sensor detects the instantaneous height h of the material 1 is zero, the bottom belt motor runs at the upper limit frequency of 50HZ, and conveys materials to the lifting belt.

[0030] When the material reaches the detection position of the laser distance sensor, measure the instantaneous height h of the material 1 , input to the PLC controller, the h 1 Substitute into the mean filter model formula: Find the instantaneous average height h 1 ;The instantaneous height h set by this method 1 The acquisition period is 0.5 seconds, and the instantaneous average height within 3 secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com