Efficient double-welding-head combined welding device

A welding device and double welding head technology, applied in welding equipment, arc welding equipment, household containers, etc., can solve the problems of low welding efficiency and difficult to guarantee welding quality, reduce labor intensity, improve welding efficiency and weld consistency Sexuality, the effect of ensuring welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

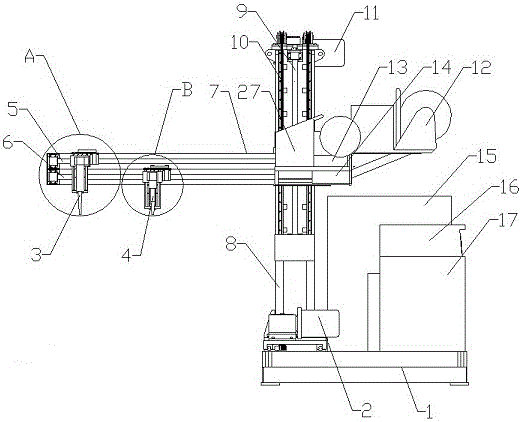

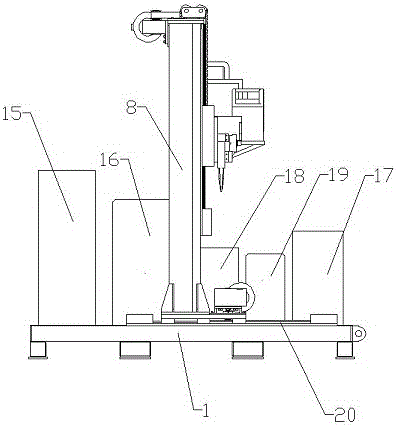

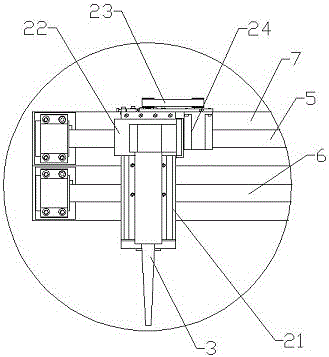

[0028] Examples such as figure 1 , figure 2 As shown, a high-efficiency double welding head combined welding device includes two sets of different welding devices. The two different welding devices can be driven by the adjustment device to adjust the multi-directional position and perform simultaneous welding.

[0029] The adjusting device is composed of an X-axis 7 , a Y-axis 20 and a Z-axis 8 which are interrelated and move relative to each other. The welding device is installed on the X-axis 7 and can move axially along the X-axis 7 .

[0030] One set of welding devices includes a first welding torch 3 , a first welding machine 17 and a first welding machine water tank 19 . The first welding torch 3 is installed on the X axis 7 and can move axially along the X axis 7 . The first welding machine 17 is an argon arc welding machine.

[0031] Another welding device includes a second welding torch 4 , a second welding machine 16 and a second welding machine water tank 18 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com