Bottom injection pouring system and its laying method

A pouring system and bottom-injection technology, which is used in casting molding equipment, metal processing equipment, casting molds, etc., can solve the problems of impurities that are not easy to float, difficult to handle, and affect the quality of castings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

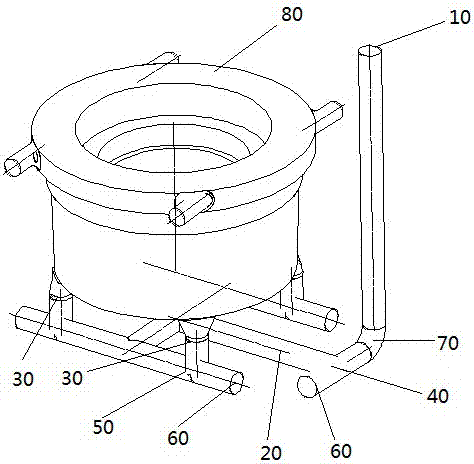

[0017] see Figure 1 to Figure 3 , The bottom pouring gating system includes a sprue 10 , a runner 20 and an inrunner 30 .

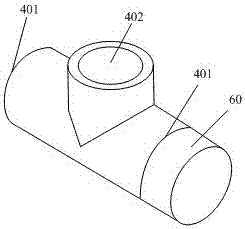

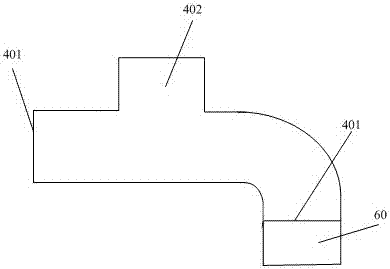

[0018] The inlet end of the sprue 10 is used to connect the sprue basin, and the outlet end of the sprue 10 is connected with the runner 20. The runner 20 is a channel vertical to the sprue 10 and arranged horizontally. The runner 20 In order to connect the passage between the sprue 10 and the ingate 30 to accommodate the flow of molten steel, the inlet end of the runner 20 is connected to the outlet end of the sprue 10, and the outlet end of the runner 20 is connected to the ingate The inlet end of the runner 30 is connected, the outlet end of the ingate 30 is used to communicate with the mold cavity 80 to be poured, and the outlet end of the sprue 10 and the inlet end of the runner 20 are connected by the first T-shaped runner 40 , the first T-shaped runner 40 is a three-way porcelain tube including two horizontal ports 401 and one vertical port 402, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com