Fertilizer screening device capable of achieving automatic cleaning

A technology of automatic cleaning and screening device, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of screen blockage, consumption of time and energy, and inability to improve production efficiency, so as to avoid wear and tear and facilitate assembly and disassembly. , the effect of the simple way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

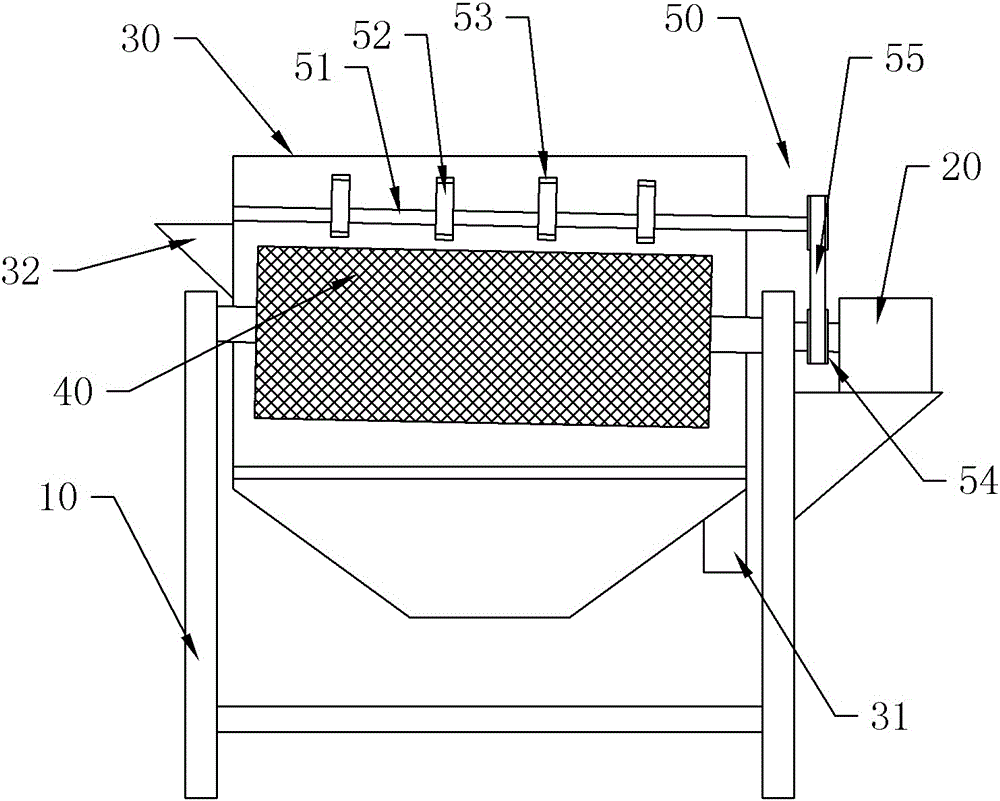

[0013] The reference signs in the accompanying drawings of the description include: frame 10, motor 20, cover body 30, coarse feed port 31, hopper 32, cylindrical screen 40, cleaning mechanism 50, rotating shaft 51, eccentric cam 52, rubber layer 53, pulley 54, belt 55.

[0014] The embodiment is basically as attached figure 1 Shown: a fertilizer screening device capable of automatic cleaning, including a frame 10, a motor 20, a cover 30 and a cylindrical screen 40, the cover 30 is fixed on the frame 10, and the cylindrical screen 40 is arranged obliquely In the cover body 30, a hopper 32 is provided on the cover body 30, and the hopper 32 is located at the high end of the cylindrical screen 40, and the side of the cover 30 near the lower end of the cylindrical screen 40 is provided with a coarse feed port 31. , the cylindrical screen 40 is driven by the motor 20, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com