Iodixanol injection and method for preparing same

An iodixanol and injection technology, which is used in the preparation of X-ray contrast agents, pharmaceutical formulations, medical preparations with inactive ingredients, etc. Improves compliance, reduces viscosity, enhances shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

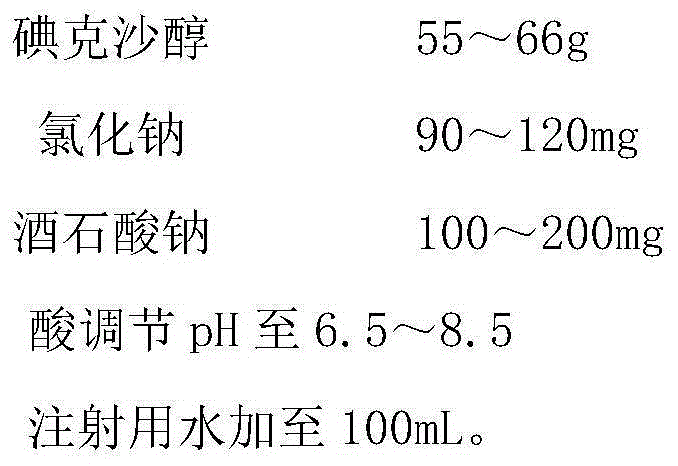

[0026] Injection prescription:

[0027]

[0028] In the scale-up production according to the above ratio, the one-time preparation volume of iodixanol is 20L.

[0029] Preparation method: (1) Add a quarter of the boiling water for injection into the liquid mixing tank, cool to 58~63℃, put in the prescription amount of sodium tartrate and stir to dissolve for 0.5h, then put in iodixanol in batches and stir Dissolve; (2) Cool down to 35~40℃, add the prescription amount of sodium chloride to the batching tank, and add water for injection to the full amount in the batching tank, add tartaric acid to adjust the pH to 7.2-7.4; (3) Add again Activated carbon, the dosage is 0.2-0.8wt% of the injection, after stirring for 15 minutes, use 0.5μm titanium rod and 0.45μm filter to remove the activated carbon; (4) Finally, sterilize (115℃, 30min), light inspection, paste Sign, package.

Embodiment 2

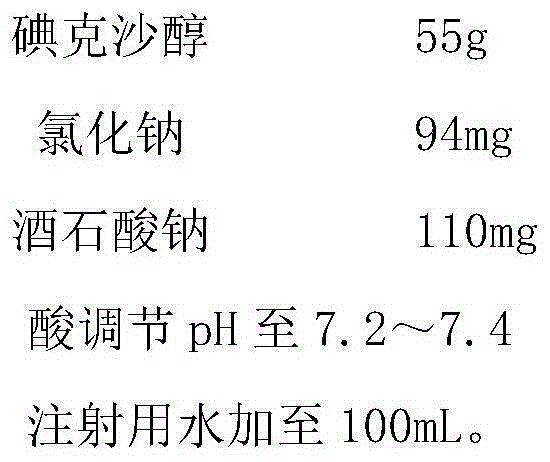

[0031] Injection prescription:

[0032]

[0033] In the scale-up production according to the above ratio, the one-time preparation volume of iodixanol is 20L.

[0034] Preparation method: (1) Add a quarter of the boiling water for injection into the liquid mixing tank, cool to 58~63℃, put in the prescription amount of sodium tartrate and stir to dissolve for 0.5h, then put in iodixanol in batches and stir Dissolve; (2) Cool down to 35~40℃, add the prescription amount of sodium chloride to the batching tank, and add water for injection to the full amount in the batching tank, add tartaric acid to adjust the pH to 7.2-7.4; (3) Add again Activated carbon, the dosage is 0.2~0.8wt% of the injection, after stirring for 15min, use 0.5μm titanium rod and 0.45μm filter to remove the activated carbon; (4) Finally, sterilize (115℃, 30min), light inspection, paste Sign, package.

Embodiment 3

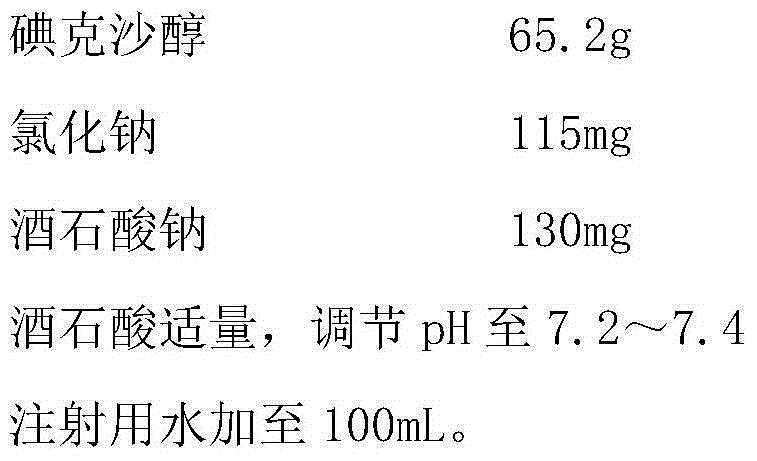

[0036] Injection prescription:

[0037]

[0038] In the scale-up production according to the above ratio, the one-time preparation volume of iodixanol is 20L.

[0039] Preparation method: (1) Add a quarter of the boiling water for injection into the liquid mixing tank, cool to 58~63℃, put in the prescription amount of sodium tartrate and stir to dissolve for 0.5h, then put in iodixanol in batches and stir Dissolve; (2) Cool down to 35~40℃, add the prescribed amount of sodium chloride into the batching tank, and at the same time add water for injection to the full volume, add phosphoric acid to adjust the pH to 6.5-7.0; (3) Add again Activated carbon, the dosage is 0.2~0.8wt% of the injection, after stirring for 15min, use 0.5μm titanium rod and 0.45μm filter to remove the activated carbon; (4) Finally, sterilize (115℃, 30min), light inspection, paste Sign, package.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com