A kind of mancozeb microcapsules and preparation method thereof

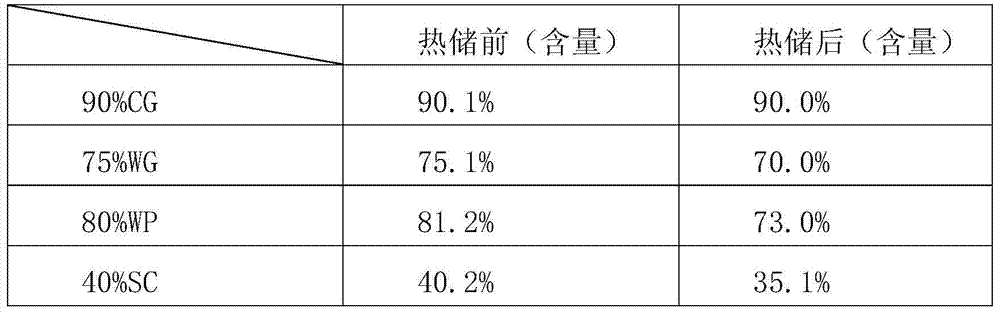

A technology of mancozeb and microcapsules, which is applied in the field of fungicides, can solve the problems of easy decomposition of products, easy occurrence of drug damage, and large dosage, and achieve the effects of low production cost, inhibition of volatilization and decomposition, and high drug efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of Microcapsules:

[0028] (1) Composition of raw material formula:

[0029] Ethylenediamine: 25%

[0030] Carbon disulfide: 15%

[0031] Manganese Sulfate 30%

[0032] Zinc Sulfate 10%

[0033] Dispersant: T20203%;

[0034] Wetting agent: T10101%;

[0035] Urea aldehyde resin 0.5%

[0036] PH regulator is: calcium lignosulfonate 7%

[0037] The balance is water.

[0038] (2) Preparation process

[0039] According to the above weight percentage, first put water and ethylenediamine into the reaction kettle, start to add carbon disulfide dropwise, increase the temperature to 50 degrees and add dropwise at a constant speed, finish adding in 30 minutes and keep stirring, the stirring speed is 300 rpm, and stir for 30 minutes After the temperature was increased to 60 degrees, manganese sulfate was added at a constant speed and added within 40 minutes. After stirring for 30 minutes, add zinc sulfate, keep the temperature at 60 degrees, stir for 1 hour, a...

Embodiment 2

[0041] Preparation of Microcapsules

[0042] (1) Composition of raw material formula

[0043] Ethylenediamine: 30%

[0044] Carbon disulfide: 20%

[0045] Manganese Sulfate 20%

[0046] Zinc Sulfate 10%

[0047] Dispersant: T20205%;

[0048] Wetting agent: T10101%;

[0049] Urea aldehyde resin 0.8%

[0050] PH regulator is: calcium lignosulfonate 5%

[0051] The balance is water.

[0052] (2) Preparation process

[0053] According to the above weight percentage, first put water and ethylenediamine into the reaction kettle, start to add carbon disulfide dropwise, increase the temperature to 50 degrees and add dropwise at a constant speed, finish adding in 30 minutes and keep stirring, the stirring speed is 300 rpm, and stir for 30 minutes After the temperature was increased to 60 degrees, manganese sulfate was added at a constant speed and added within 40 minutes. After stirring for 30 minutes, add zinc sulfate, keep the temperature at 60 degrees, stir for 1 hour, adj...

Embodiment 3

[0055] Preparation of Microcapsules

[0056] (1) Composition of raw material formula:

[0057] Ethylenediamine: 30%

[0058] Carbon disulfide: 20%

[0059] Manganese Sulfate 20%

[0060] Zinc Sulfate 10%

[0061] Dispersant: T20205%;

[0062] Wetting agent: T10101%;

[0063] Urea aldehyde resin 0.8%

[0064] PH regulator is: calcium lignosulfonate 5%

[0065] The balance is water.

[0066] (2) Preparation process

[0067]According to the above weight percentage, first put water and ethylenediamine into the reaction kettle, start to add carbon disulfide dropwise, increase the temperature to 50 degrees and add dropwise at a constant speed, finish adding in 30 minutes and keep stirring, the stirring speed is 400 rpm, and stir for 30 minutes After the temperature was increased to 60 degrees, manganese sulfate was added at a constant speed and added within 40 minutes. After stirring for 30 minutes, add zinc sulfate, keep the temperature at 60 degrees, stir for 1 hour, adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com