Layout wiring method for simple tin stove carrier model of printed circuit board

A printed circuit board, layout and wiring technology, applied in the field of electronics, can solve problems such as high defective rate of product manufacturing process, empty or false soldering, and virtual soldering of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

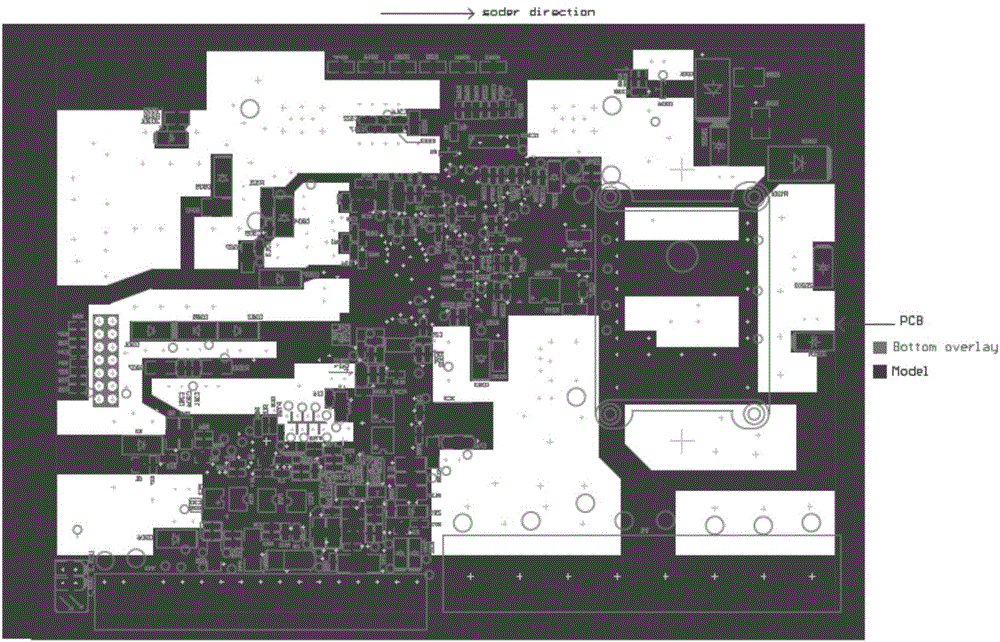

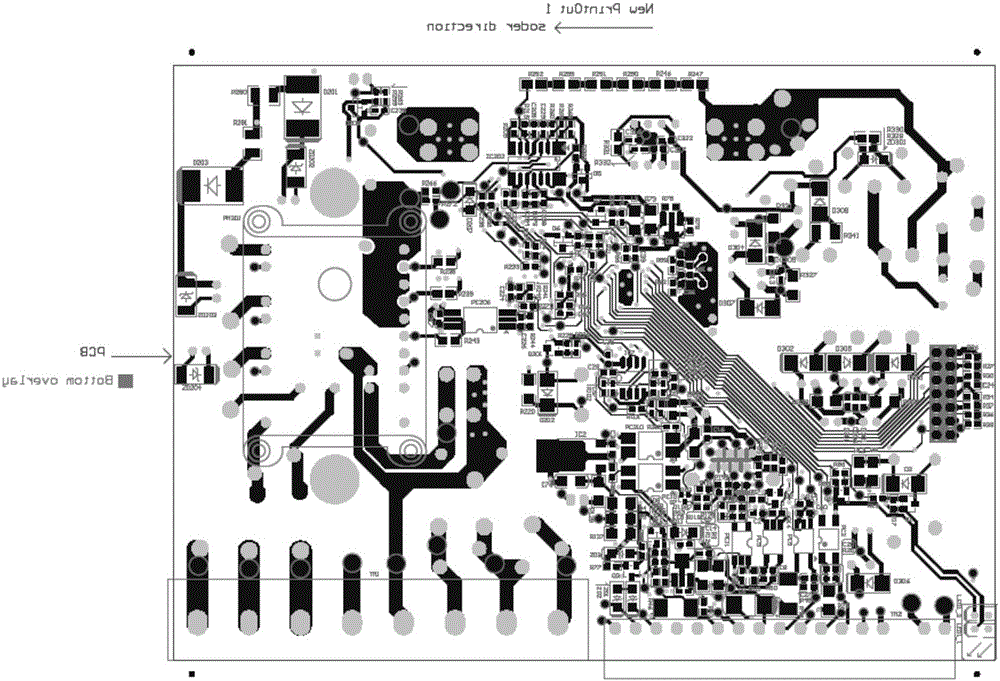

[0026] The present invention establishes a plane carrier model during PCB layout and wiring for the PCB with double-sided solder paste carrier passing through the soldering furnace, and presents the carrier model in an intuitive manner as a reference for the PCB carrier manufacturing process to ensure that the layout and wiring are completed The PCB becomes a practical and effective PCB design. The invention is suitable for electronic and electrical products that perform the PCB carrier wave soldering process. As long as the pre-designed PCB adopts the carrier wave soldering process, the design of the PCB carrier model is applicable to the present invention. The following takes the PCB of a certain electronic product as an example for specific instructions:

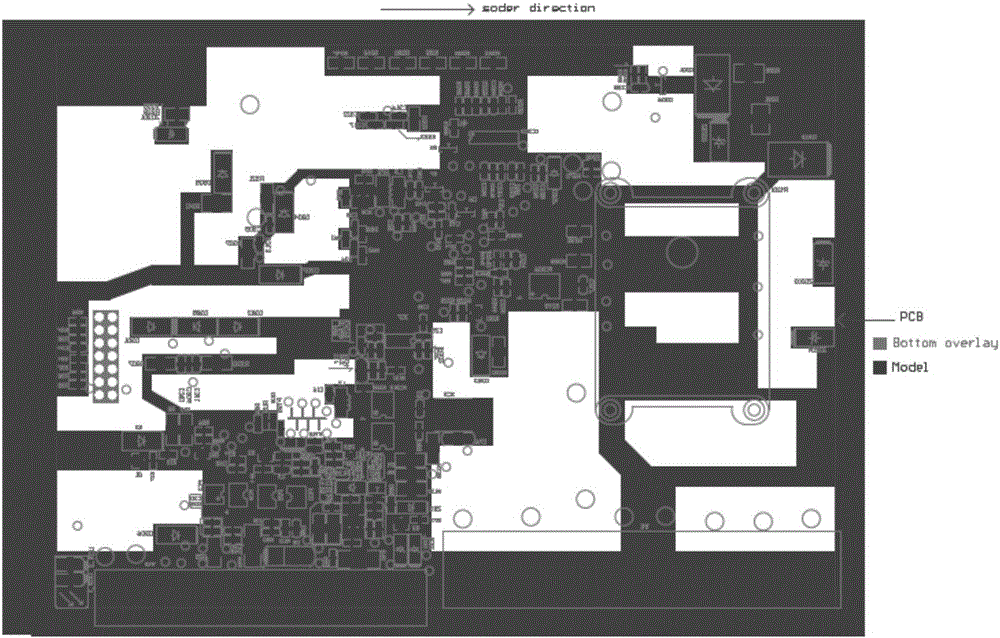

[0027] First, establish a model of the plane carrier during PCB layout, such as figure 1 Shown is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com