Wire distribution device for secondary conducting wire harness manufacturing

A technology for wiring equipment and secondary wires is applied in the field of wiring equipment for the manufacture of secondary wire harnesses, which can solve the problems that wiring components cannot fully simulate wire harnesses, wire harness product size errors, and inconvenient size constraints on wires, etc. Accurate dimensions and improved wiring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

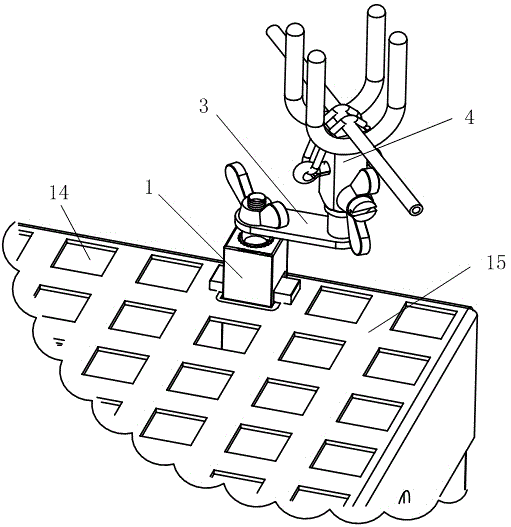

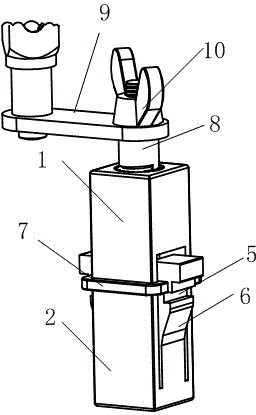

[0028] Such as Figure 1~3 The shown wiring equipment for the manufacture of secondary wire harnesses includes a positioning installation device 1, and a patch strip 2 is arranged under the positioning installation device 1. , the positioning installation device 1 used in the present invention is connected with a rotation adjustment device 3 . At the same time, in order to meet the positioning of the wire harness and perform corresponding wiring arrangement or wiring simulation, the wire harness will not be loosened, and the wire bundle device 4 is connected to the rotating adjustment device 3 .

[0029] As far as a preferred embodiment of the present invention is concerned, in order to facilitate quick installation and disassembly on the subsequent workbench 15 having a square installation hole 14, the positioning installation device 1 can be formed by a resin material at one time, and the positioning installation device 1 There are positioning components distributed in pair...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com