Real-time monitoring method of milk coagulation process based on incremental principal component analysis

A principal component analysis and coagulation process technology, applied in the analysis of materials, material analysis through optical means, measuring devices, etc., can solve problems such as high cost, affecting work efficiency, hindering process automation, etc., and achieve high accuracy and reliable data The effect of the analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention. Any modifications and / or changes made to the present invention will fall within the protection scope of the present invention.

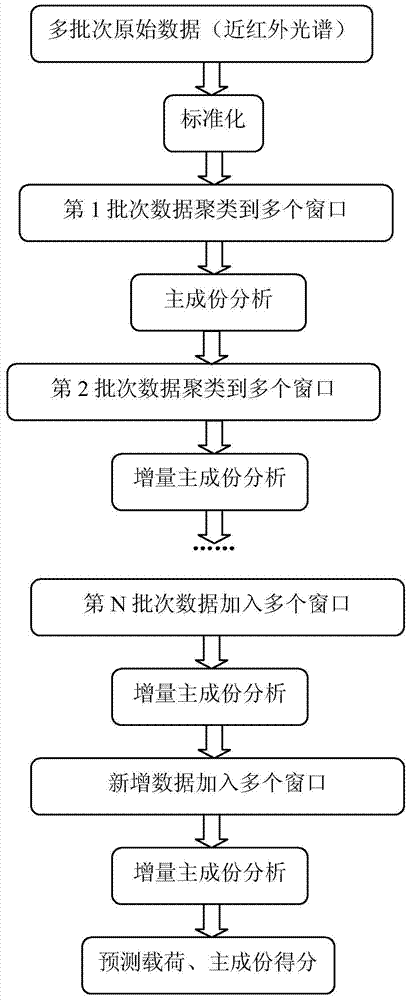

[0046] Embodiment of the present invention: the milk coagulation process real-time monitoring method based on incremental principal component analysis, such as figure 1 shown, including the following steps:

[0047] S1. Collecting multiple batches of near-infrared spectral data at various time points during the milk coagulation process as raw data;

[0048] S2. Perform standardized preprocessing on the raw data to obtain multiple batches of standardized data;

[0049] S3. Perform a clustering operation on the first batch of standardized data through a clustering algorithm to generate multiple clusters, and identify these clusters as different windows;

[0050] S4. Perform principal component analysis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com