Air conditioner

An air conditioner and air outlet technology, applied in the field of air conditioning equipment, can solve the problems of low assembly efficiency, complex structure, and low reliability, and achieve the effects of improving assembly efficiency, high reliability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

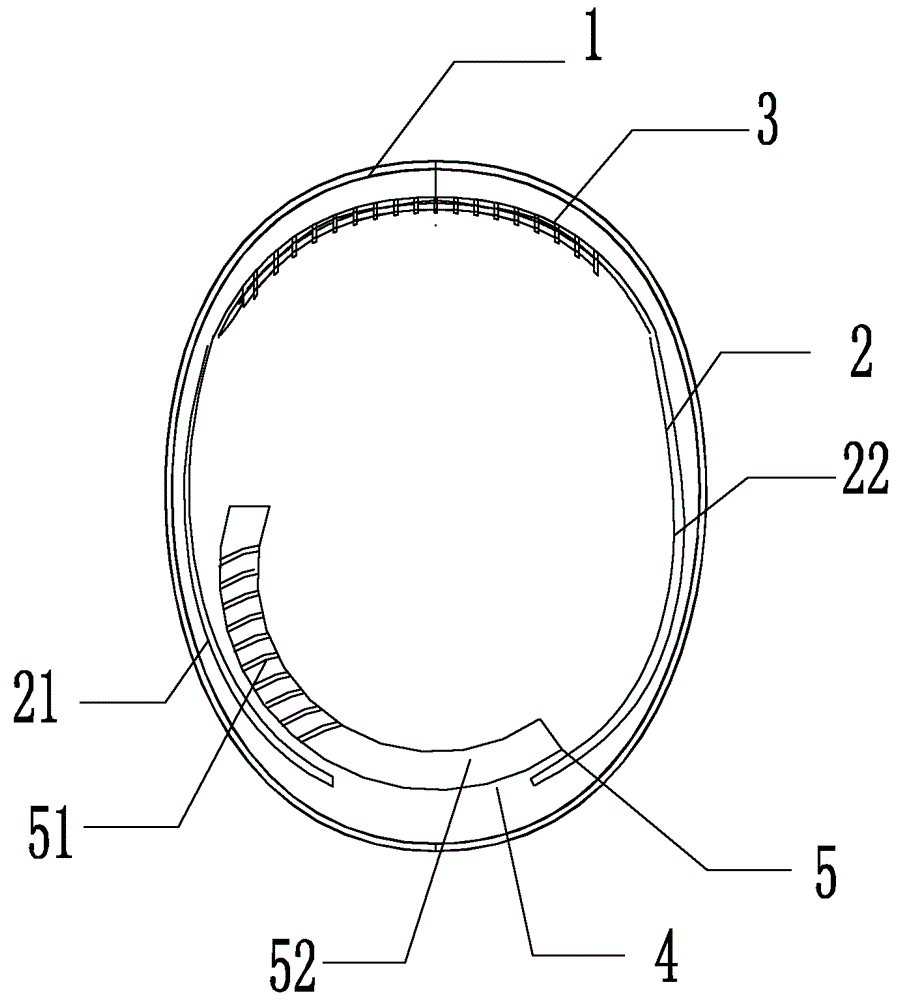

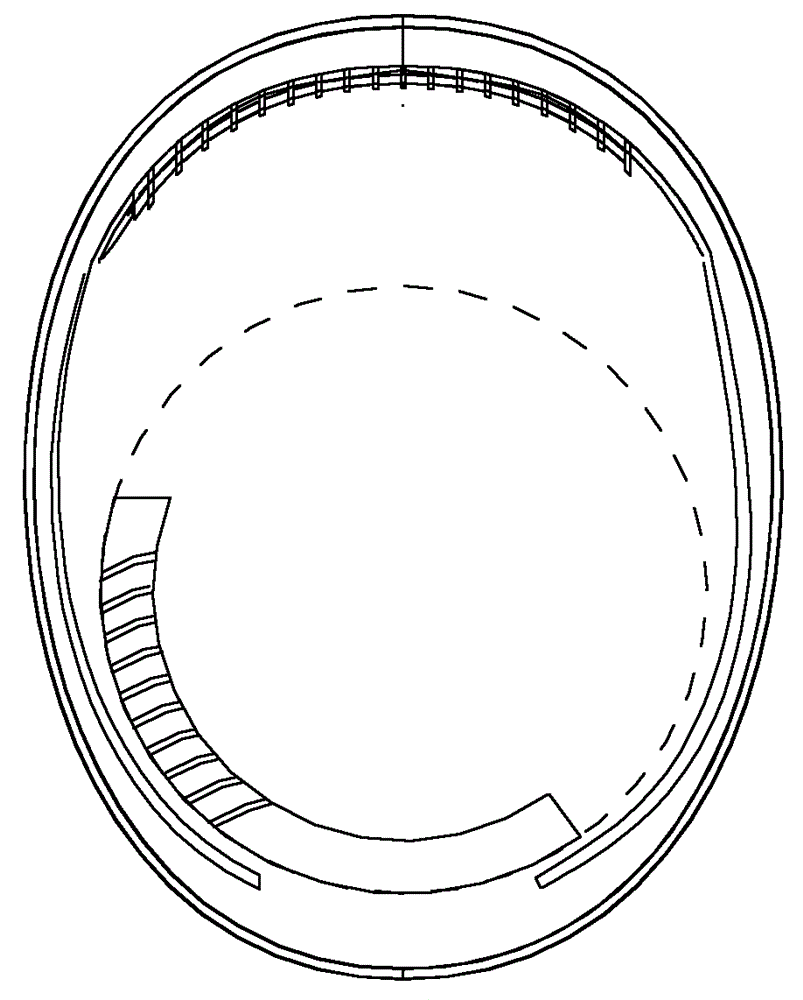

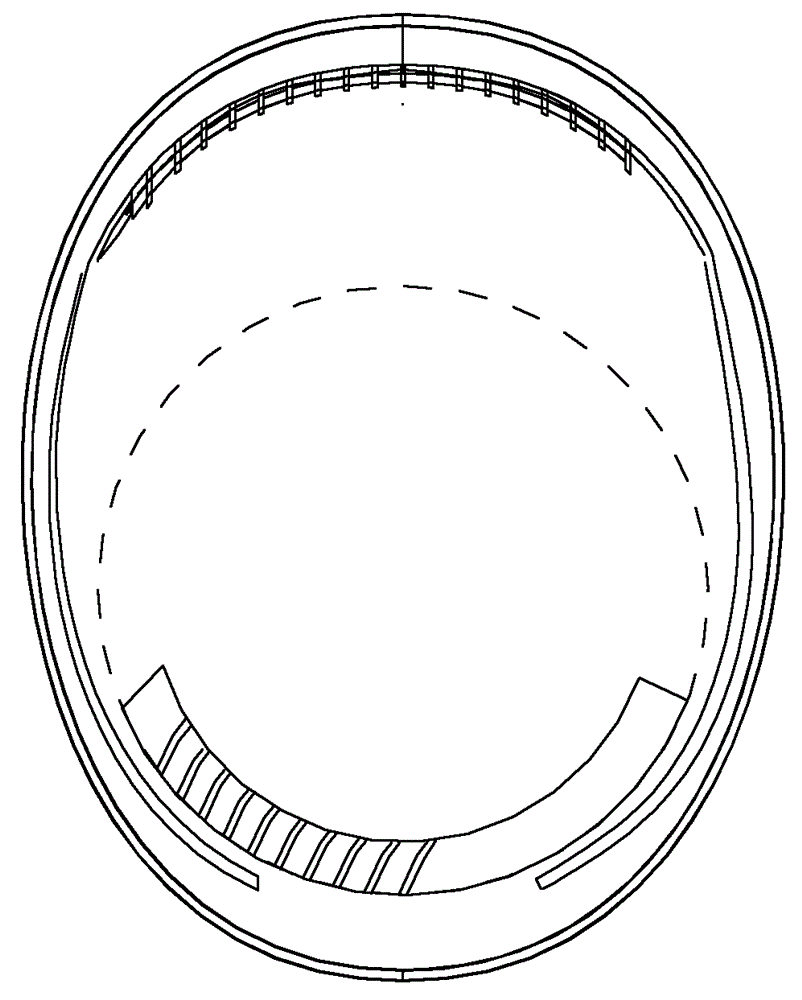

[0024] This embodiment discloses an air conditioner, such as figure 1 , 2 , 3, and 4, it includes a housing 2 and a chassis 1, the air intake grille 3 is located at the side or rear of the housing 2; the air outlet 4 is located at the front of the housing 2; the housing 2 includes a left decorative plate and the right decorative panel 22, the air outlet 4 is located in the area between the left decorative panel and the right decorative panel 22; the air outlet guide and closing device 5 is located inside the housing; the air outlet grille part 51 and the door panel part 52 Located on both sides of the air guiding and closing device 5 at the air outlet.

[0025] Preferably, the air conditioner is a cabinet-type air conditioner with an elliptical cross-section, the cross-section of the air guide and closing device at the air outlet adopts a fan ring structure, and the center of the air guide and closing device 5 at the air outlet is in line with the air conditioner. The center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com