High-efficiency combined hydrate inhibitor

A hydrate inhibitor and combined use technology, which is applied in the field of high-efficiency combined use type hydrate inhibitor, can solve the problems of large addition amount and poor inhibition performance, and achieves preventing the accumulation of hydrate particles, solving the problem of flow safety, and achieving good application. Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

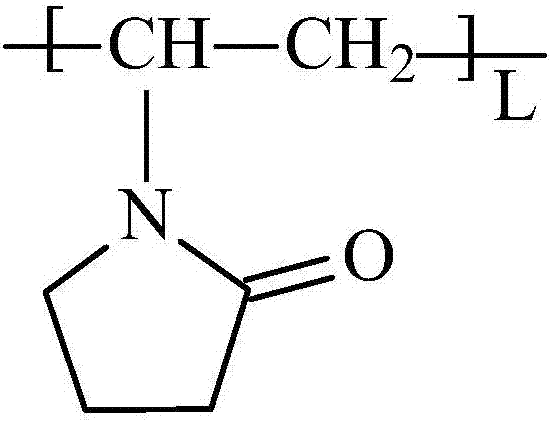

[0047] The high-efficiency combined hydrate inhibitor provided in this example is obtained by mixing polyvinylpyrrolidone, Span20 and lauryl betaine in a mass ratio of 1:1:1.

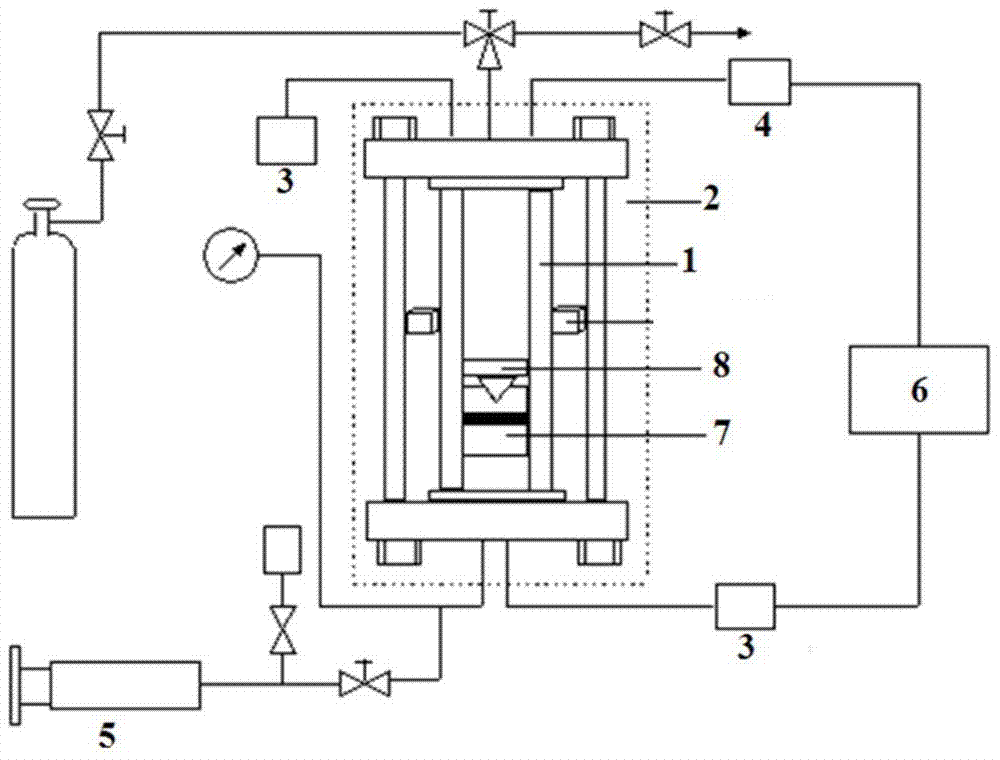

[0048] The present embodiment uses the described high-pressure sapphire reactor for evaluation. The oil-water system in the reactor is composed of 1.5ml deionized water and 13.5ml of -20# diesel oil, that is, the oil-water system with a water content of 10vol%. The addition amount of the type hydrate inhibitor is 2.0% of the water mass in the system, and the experimental gas composition introduced is shown in Table 1.

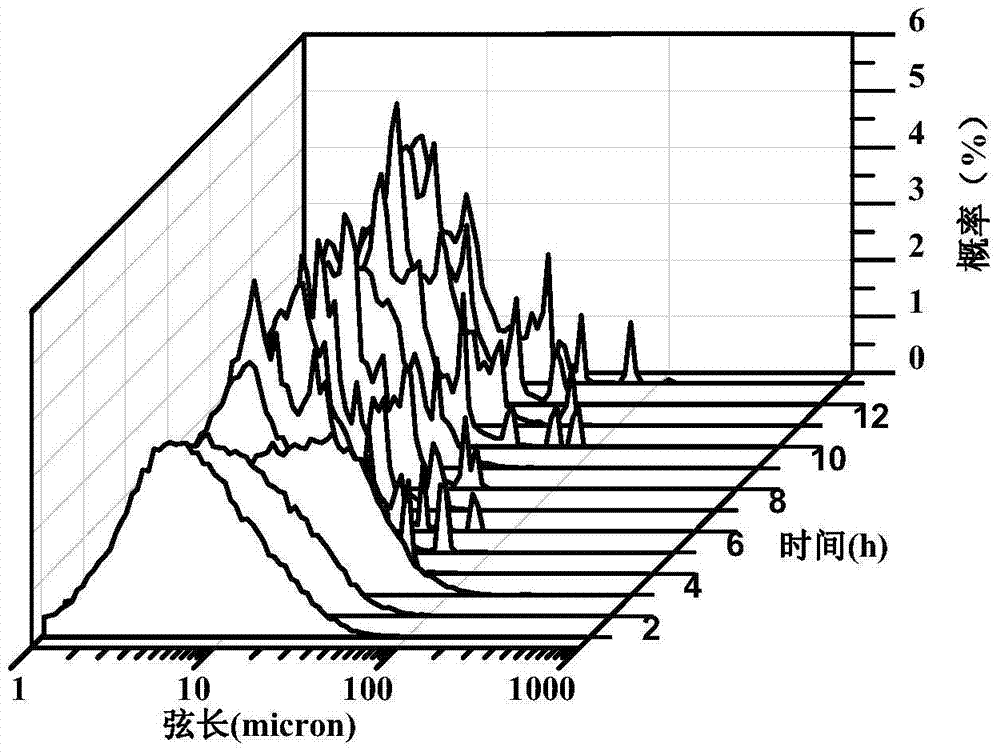

[0049] During the experiment in this example, it was found that the hydrate particles were evenly dispersed in the oil phase, without deposition and clogging, and the stirrer in the reactor could move up and down freely; after stopping the stirring for 12 hours, it could still be restarted smoothly without deposition, thus indicating that The inhibitor provided in this example has good i...

Embodiment 2

[0051] The high-efficiency combined hydrate inhibitor provided in this example is obtained by mixing polyvinylpyrrolidone, Span20 and lauryl betaine in a mass ratio of 2:1:1.

[0052] The present embodiment uses the described high-pressure sapphire reactor for evaluation. The oil-water system in the reactor is composed of 1.5ml deionized water and 13.5ml of -20# diesel oil, that is, the oil-water system with a water content of 10vol%. The addition amount of the type hydrate inhibitor is 2.0% of the water mass in the system, and the experimental gas composition introduced is shown in Table 1.

[0053] In the experimental process of this example, it was found that throughout the experimental process, the hydrate particles were evenly dispersed in the oil phase, no deposition and clogging occurred, and the stirring bar of the reactor could move up and down freely; after stopping stirring for 12 hours, it could still be restarted smoothly. There is no deposition, which shows that ...

Embodiment 3

[0055] The high-efficiency combined hydrate inhibitor provided in this example is obtained by mixing polyvinylpyrrolidone, Span20 and lauryl betaine in a mass ratio of 1:1:1.

[0056] This embodiment uses the high-pressure sapphire reactor for evaluation. The oil-water system in the reactor is composed of 3.0ml deionized water and 12ml of -20# diesel oil, that is, the oil-water system with a water content of 20vol%. The addition amount of type hydrate inhibitor is 2.0% of the water mass in the system, and the experimental gas composition introduced is shown in Table 1.

[0057] In the experimental process of this example, it was found that throughout the experimental process, the hydrate particles were evenly dispersed in the oil phase, no deposition and clogging occurred, and the stirring bar of the reactor could move up and down freely; after stopping stirring for 12 hours, it could still be restarted smoothly. There is no deposition, which shows that the inhibitor provided ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com