Steel strand with polyurea protection material on outer layer and manufacturing method of steel strand

A protective material, steel strand technology, applied in the field of anti-corrosion steel strand and its production, can solve the problems of aging phenomenon, shedding, poor wear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

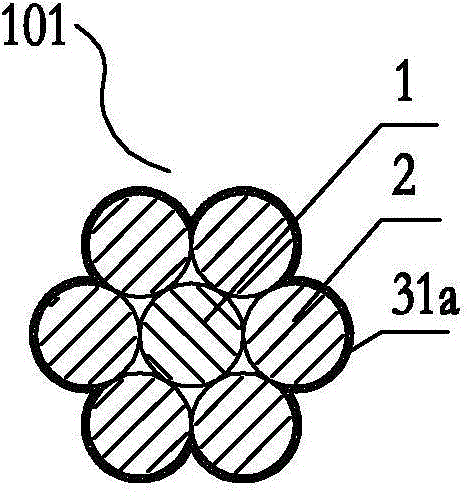

[0139] A steel strand coated with anti-corrosion paint on the outer periphery of the steel strand and with a polyurea protective material on the outer layer. It is formed by twisting a central wire 1 and a side wire 2. The center wire and the side wire are made of ordinary steel wire or Smooth steel wire made of high-strength steel wire. The steel strand has a layer of polyurea protective coating I31a formed of polyurea anti-corrosion material on the outer circumference of the entire steel strand, that is, Picture 1-1Shown is a steel strand I1 with an outer layer of polyurea protective material.

[0140] As a transformation of Embodiment 1 of the present invention, the following types are included:

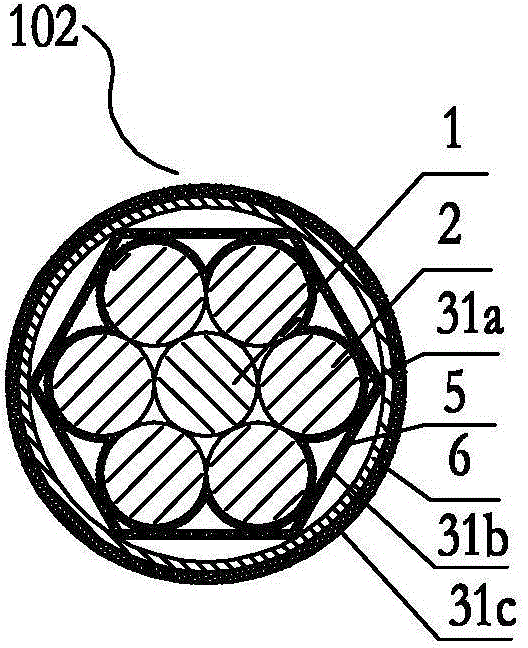

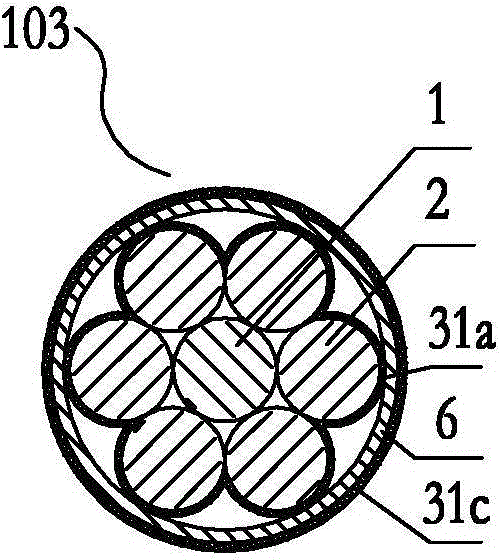

[0141] 1. The outside of the steel strand with polyurea protective material on the outer layer is covered with wrapping tape 5 as a whole, and the outside of wrapping tape 5 is coated with a layer of polyurea protective coating II 31b as a whole, and then covered with PE protecti...

Embodiment 2

[0147] A kind of steel strand that is coated with a layer of polyurea protective coating on the outer periphery of the whole steel strand, and the outer layer of polyurea protective material is filled with polyurea anti-corrosion material in the gap between the central wire and the side wire, It is formed by twisting the central wire 1 and the side wire 2. The center wire and the side wire are smooth steel wires made of ordinary steel wire or high-strength steel wire. The steel strand is coated with a Polyurea protective coating I31a formed by polyurea anti-corrosion material, and a steel strand II1 with polyurea anti-corrosion material on the outer layer composed of polyurea anti-corrosion material 32 filled in the gap between the central wire and side wires ( see diagram 2-1 ).

[0148] As the conversion of Embodiment 2 of the present invention, the following types are included:

[0149] 1. The outer layer of steel strand II1 with polyurea protective material is covered w...

Embodiment 3

[0173] A method for manufacturing a steel strand with a polyurea protective material on the outer layer. The manufacturing method is to first twist the central wire 1 and the side wire 2 to form a steel strand, and then coat the outer circumference of the entire steel strand A layer of polyurea anti-corrosion material forms the polyurea protective coating I31a, and the outer circumference of the entire steel strand is coated with a layer of polyurea protective coating, which is a steel strand with an outer layer of polyurea protective material.

[0174] Its main steps include:

[0175] The main steps include: A, steel wire pretreatment, B, twisting the pretreated center wire and side wire to make a steel strand, C, polyurea material coating process I;

[0176] A. Steel wire pretreatment: the central wire 1 and side wire 2 composed of smooth steel wire or anti-corrosion steel wire are pretreated to make qualified steel wire. The pretreatment includes steps A1 and A2:

[0177] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com