Washing machine drainage control method

A control method and washing machine technology, applied in the control device of washing machine, washing device, textile and paper making, etc., can solve the problems of filter clogging, affecting the effect of lint collection, weak water flow rate of the filter, etc. Cleaning effect, effect of increasing discharge speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

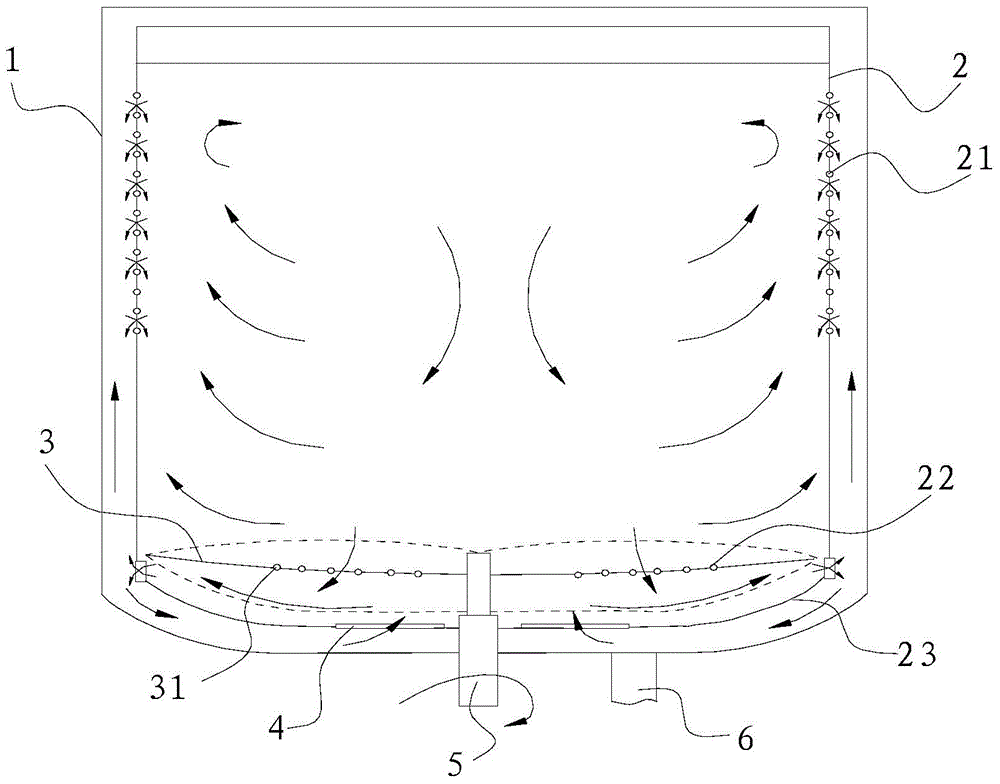

[0037] This preferred embodiment provides a washing machine drainage control method. The method is to control the rotation speed of the inner tub and / or the pulsator during the drainage process, and control the flow rate of the washing liquid by controlling the rotation speed of the inner tub and / or the pulsator to backwash and clean the filter screen. Specifically, during the drainage process, the rotation speed of the inner tub and / or the pulsator is set according to the water level in the washing machine, so that the inner tub and / or the pulsator rotate at different speeds at different water levels.

[0038] Such as Figure 4 The method shown includes the following specific steps:

[0039] Step 1. Set two calibration values for the water level in the washing machine, assigning i=1.

[0040] Step 2. The computer board program controls to open the drain valve and start draining.

[0041] Step 3. Determine whether the current water level value is lower than or equal to th...

Embodiment 2

[0051] This preferred embodiment provides a washing machine drainage control method, which is basically the same as the first preferred embodiment.

[0052] The difference is that: when the water level is lower than or equal to the set value Hs, the drain valve is closed, and the inner tub and / or the pulsator rotates at the set speed Vs; after turning Ts for a time, the drain valve is reopened. The water level value can be specifically set according to needs. Temporarily closing the drain valve allows the existing washing liquid in the bucket to flush the filter screen for a longer period of time, and the cleaning effect on the filter screen is better.

[0053] When i=1, the inner barrel and / or the pulsator rotate forward, when i=2, the inner barrel and / or the pulsator reverse; or, when i=1, the inner barrel and / or the pulsator reverse, when i=2, the inner barrel and / or the pulsator is running forward. The forward and reverse rotation of the inner barrel and / or the pulsator ...

Embodiment 3

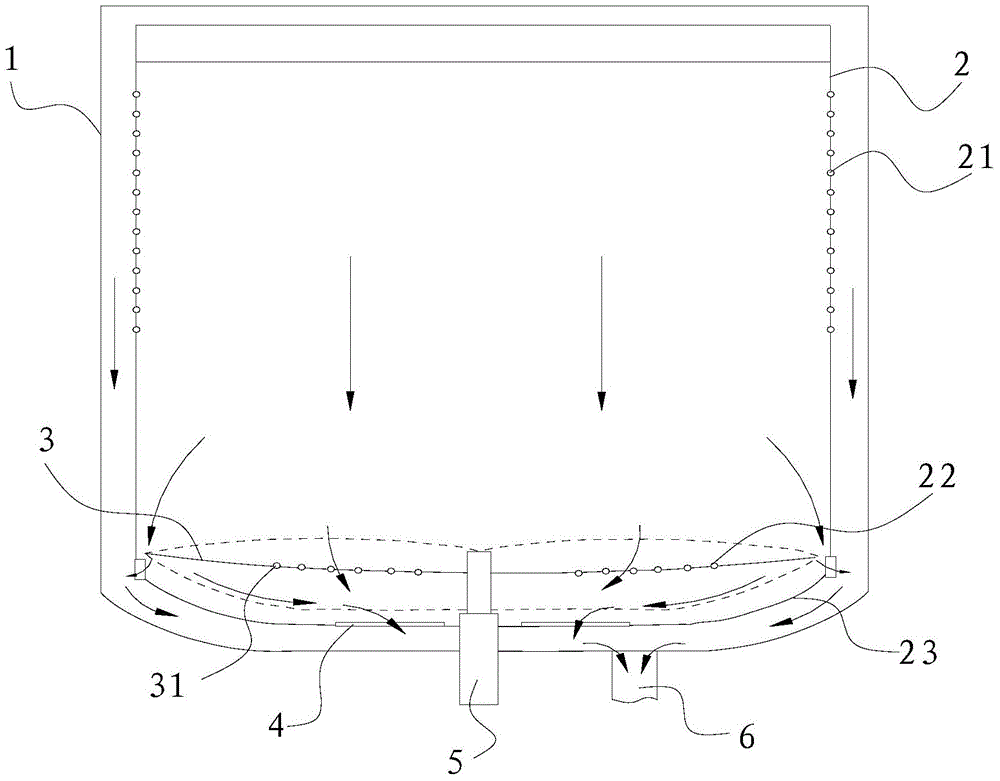

[0055] This preferred embodiment provides a washing machine drainage control method. Such as Figure 5 The method shown includes the following specific steps:

[0056] Step 1. Set N calibration values for the water level in the washing machine, where N is a positive integer greater than or equal to 1; 1≤i≤N, assign i=1;

[0057] Step 2. Open the drain valve and start draining water;

[0058] Step 3. Determine whether the current water level value is lower than or equal to the set water level value Hi, and if so, go to step 4; otherwise, continue to detect the current water level value and judge until the current water level value is lower than or equal to the set water level value Hi and go to step 4 ;

[0059] Step 4, controlling the rotation speed of the inner barrel and / or the pulsator to be Vi;

[0060] Step 5, determine whether i is equal to N, if so, go to step 6; otherwise, i=i+1, go to step 3;

[0061] Step 6, end.

[0062] The value of N can be set according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com