False twisting device for open-end spinning device

A technology of open-end spinning and false twisting, which is used in spinning machines, open-end spinning machines, and continuously wound spinning machines to achieve the effect of improving spinning stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

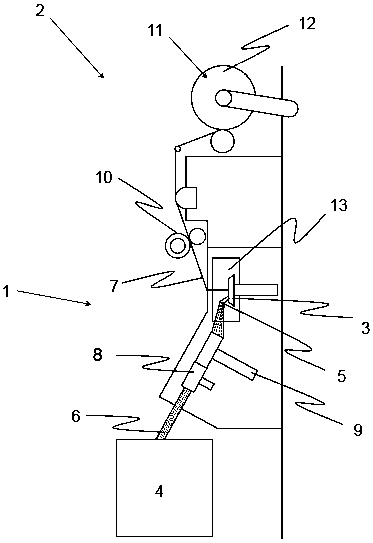

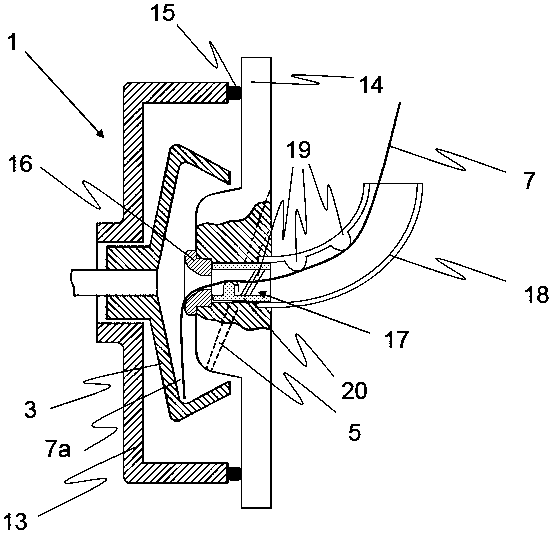

[0032] figure 1A schematic side view of the rotor spinning device 1 of the rotor spinning machine 2 is shown. In this case, the rotor spinning machine 2 comprises a plurality of working points arranged side by side in the longitudinal direction of the spinning machine 2 . Each working point here generally comprises a feed device 8 which feeds the fiber material 6 to the air spinning device 1 via a loosening device 9 which loosens the fiber material 6 into individual fibers. In this case, the fiber material 6 is stored in a storage container 4 on the rotor spinning machine 2 . The fibrous material 6 that is loosened into individual fibers finally passes through the fiber feed channel 5 (see figure 2 ) is delivered to the spinning rotor 3 of the air spinning device 1. The yarn 7 produced in the spinning rotor 3 is finally withdrawn from the open-end spinning device 1 by means of a withdrawal device 10 and wound onto a bobbin 12 by means of a winding device 11 .

[0033] Air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com