High-density fermentation medium and fermentation technology for forage-use enterococcus faecium

A high-density fermentation and fermentation medium technology, applied in the field of high-density fermentation medium and its fermentation process, can solve the problems of low fermentation level, high price, increased cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

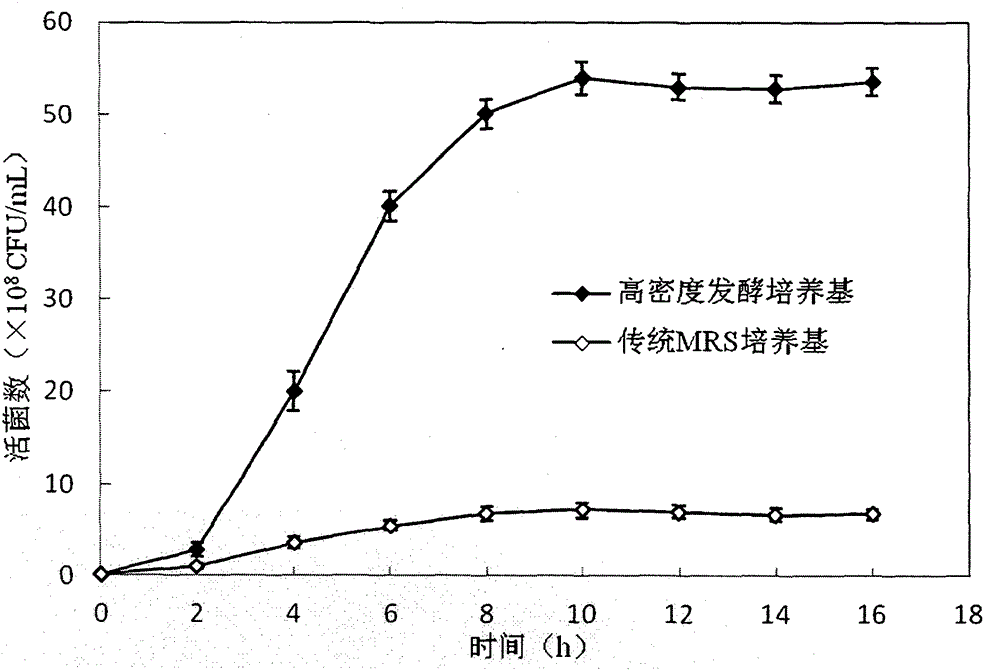

[0036] Embodiment one: the preparation of high-density seed medium and fermentation medium and the comparison of the number of fermentation viable bacteria

[0037] 1. The main components and contents of the high-density fermentation seed medium and fermentation medium of Enterococcus faecium WEI-10CGMCCNo.7746 are as follows:

[0038] Fish peptone 15-20g / L, sucrose 15-25g / L, sodium acetate trihydrate 3-7g / L, dipotassium hydrogen phosphate trihydrate 1-4g / L, ammonium citrate 1-4g / L, magnesium sulfate heptahydrate 0.05-0.4g / L, manganese sulfate monohydrate 0.02-0.2g / L, Tween 800.5-2g / L.

[0039] The ingredients and composition of the preferred seed and fermentation medium are: fish peptone 17g / L, sucrose 19g / L, sodium acetate trihydrate 5g / L, dipotassium hydrogen phosphate trihydrate 2g / L, ammonium citrate 2g / L, seven Magnesium sulfate hydrate 0.2g / L, manganese sulfate monohydrate 0.05g / L, Tween 801g / L.

[0040] 2. The preparation method of seed shake flask medium is as follo...

Embodiment 2

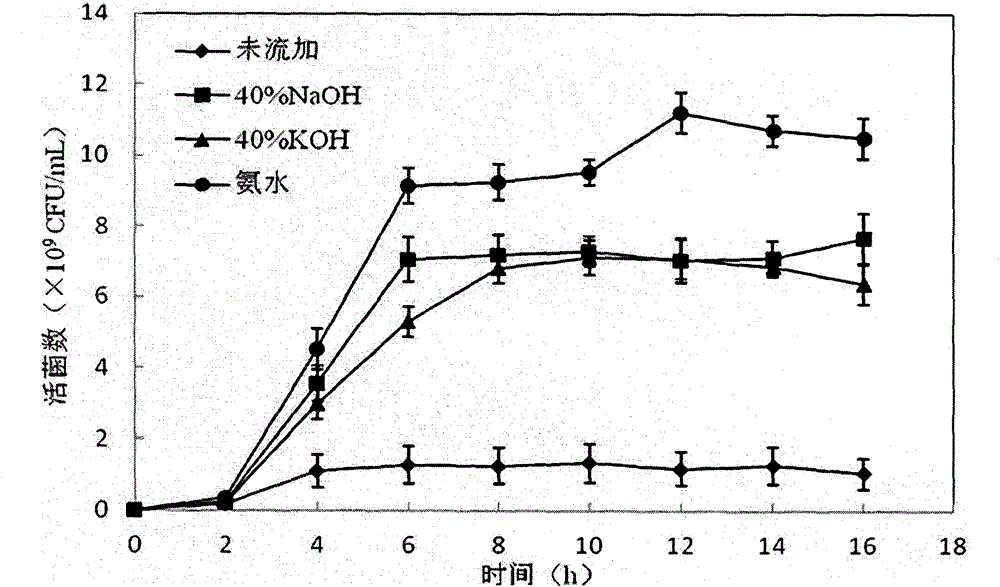

[0063] Embodiment two: the optimization of most suitable alkaline pH neutralizer

[0064] 1. Ingredients and preparation of seeds and fermentation medium:

[0065] The main components and contents of seeds and fermentation medium are: fish peptone 17g / L, sucrose 19g / L, sodium acetate trihydrate 5g / L, dipotassium hydrogen phosphate trihydrate 2g / L, ammonium citrate 2g / L, heptahydrate Magnesium sulfate 0.2g / L, manganese sulfate monohydrate 0.05g / L, Tween 801g / L.

[0066] The seed shake flask medium preparation method is as follows:

[0067] Weigh each component of the medium, fully dissolve, adjust the pH to 8.0 with 40% sodium hydroxide solution, adjust the volume to the required volume, and sterilize at 121°C for 20 minutes.

[0068] The fermentation tank medium preparation method is as follows:

[0069] (1) Fill 17g / L sodium hydroxide solution in the fermenter, the filling volume is 60%, 0.11-0.16Mpa sterilizes 1h, discharge liquid after cooling, empty the fermenter after ...

Embodiment 3

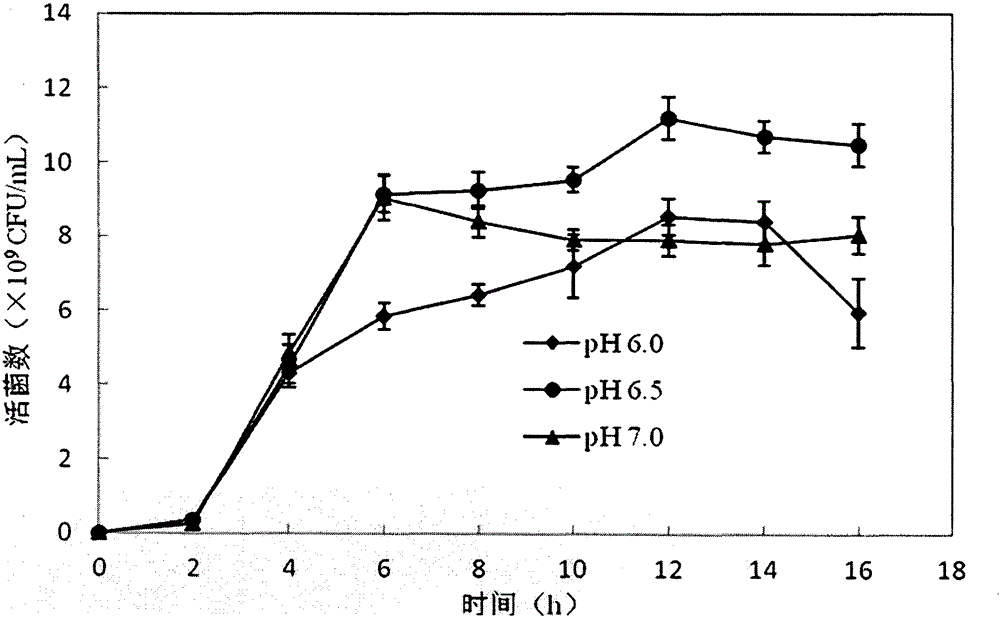

[0080] Embodiment three: the optimization of optimum constant pH

[0081] 1. Ingredients and preparation of seeds and fermentation medium:

[0082] The main components and contents of seeds and fermentation medium are: fish peptone 17g / L, sucrose 19g / L, sodium acetate trihydrate 5g / L, dipotassium hydrogen phosphate trihydrate 2g / L, ammonium citrate 2g / L, heptahydrate Magnesium sulfate 0.2g / L, manganese sulfate monohydrate 0.05g / L, Tween 801g / L.

[0083] The seed shake flask medium preparation method is as follows:

[0084] Weigh each component of the medium, fully dissolve, adjust the pH to 8.0 with 40% sodium hydroxide solution, adjust the volume to the required volume, and sterilize at 121°C for 20 minutes.

[0085] The fermentation tank medium preparation method is as follows:

[0086] (1) Fill 17g / L sodium hydroxide solution in the fermenter, the filling volume is 60%, 0.11-0.16Mpa sterilizes 1h, discharge liquid after cooling, empty the fermenter after rinsing fermente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com