A kind of extraction method of tangerine peel oil

An extraction method and tangerine peel technology are applied in the field of extraction technology of tangerine peel oil to achieve the effects of pure and rich aroma, no irritating odor and no pungent taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

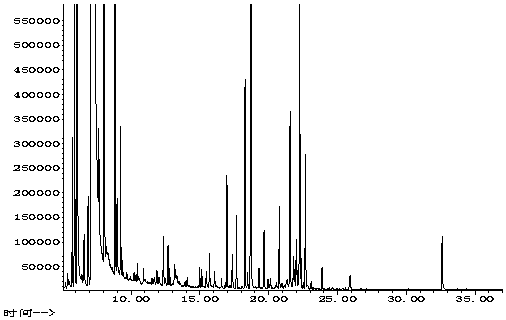

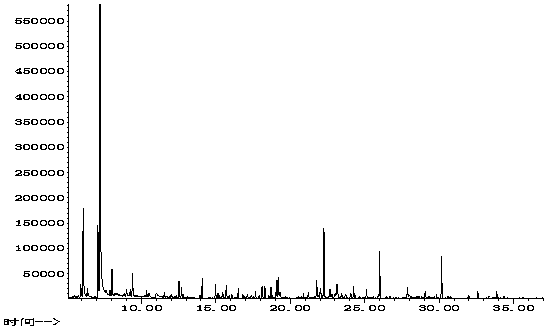

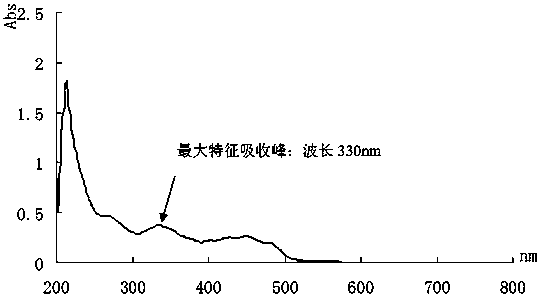

Embodiment 1

[0028] Take a certain amount of tangerine peel, and use a liquid nitrogen pulverizer to crush the tangerine peel to 100 mesh, while controlling the water content at 15%, to obtain the raw material of tangerine peel. Take 8.055kg of tangerine peel raw material, use mixed alkanes (propane:butane=1:1), the weight volume ratio of tangerine peel raw material and mixed alkanes is 1:4, and extract at 25°C and 0.5 MPa for 35min. The extracted tangerine peel raw materials were treated with supercritical CO 2 Carry out extraction, and control temperature is 50 ℃, and pressure is 20MPa, and extraction time is 50min, and orange peel oil 0.554kg is obtained through analytical separation, and this orange peel oil is bright yellow in color, pure and rich in fragrance, has no irritating smell, has no pungent taste, and the original orange peel oil It has a high degree of flavor retention and rich functional ingredients. The content of polymethoxylated flavonoids measured by ultraviolet spectr...

Embodiment 2

[0030] Take a certain amount of tangerine peel, and use a liquid nitrogen pulverizer to crush the tangerine peel to 90 mesh, while controlling the water content to 20%, to obtain the raw material of tangerine peel. Take 7.876kg of tangerine peel raw material, use mixed alkanes (propane:butane=1:2), the weight volume ratio of tangerine peel raw material and mixed alkanes is 1:5, and extract at 30°C and 0.4 MPa for 30min. The extracted tangerine peel raw materials were treated with supercritical CO 2 Carry out extraction, and control temperature is 60 ℃, and pressure is 15MPa, and extraction time is 60min, and orange peel oil 0.503kg is obtained through analyzing and separating, and this orange peel oil is bright yellow in color, pure and rich in fragrance, has no irritating smell, has no pungent taste, and orange peel oil is original It has a high degree of flavor retention and rich functional ingredients. The content of polymethoxylated flavonoids measured by ultraviolet spect...

Embodiment 3

[0032] Take a certain amount of tangerine peel, and use a liquid nitrogen pulverizer to crush the tangerine peel to 80 mesh, while controlling the water content to 20%, to obtain the raw material of tangerine peel. Take 7.567kg of tangerine peel raw material, use mixed alkanes (propane:butane=1:3), the weight volume ratio of tangerine peel raw material and mixed alkanes is 1:3, and extract at 35°C and 0.2 MPa for 40min. The extracted tangerine peel raw materials were treated with supercritical CO 2 Carry out extraction, and control temperature is 65 ℃, and pressure is 10MPa, and extraction time is 70min, and orange peel oil 0.489kg is obtained through analytical separation, and this orange peel oil color is bright yellow, and aroma is pure and strong, has no irritating smell, has no pungent taste, and orange peel oil is original It has high flavor retention and rich functional ingredients. The content of polymethoxylated flavonoids measured by ultraviolet spectrophotometer is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com