A kind of tripolyphosphazene cross-linked rare earth complex luminescent material and preparation method thereof

A technology of tripolyphosphazene and luminescent materials, which is applied in the directions of luminescent materials, chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, etc., can solve the problems of weak luminescence intensity of rare earth complexes, and achieve excellent luminescence performance , The effect of high color purity and many luminous centers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

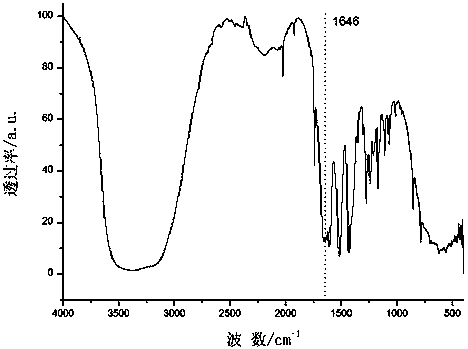

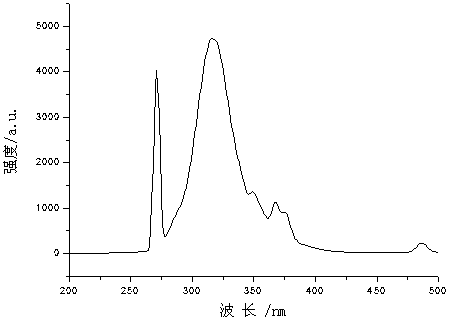

[0029] Example 1: The preparation method of trimeric phosphazene cross-linked rare earth complex luminescent material:

[0030] S1: In a 250ml single-necked flask, add 100ml of tetrahydrofuran in turn, 2.50g (7.19mmol) of hexachlorocyclotrimeric phosphazene, 7.13g (51.59mmol) of p-hydroxybenzoic acid, and 11.3g of potassium carbonate (82.30mmol), at 66 o C under heating and stirring, condensed and refluxed for 48h.

[0031] S2: After the reaction is complete, change to a distillation device to distill off the solvent tetrahydrofuran; then dissolve the product with DMF and stir for 12 hours. After filtration, a clear filtrate was obtained. After half of the filtrate was evaporated, the product was finally reprecipitated with ethyl acetate, washed three times with ethyl acetate, and dried in vacuum for 12 hours.

[0032] S3: Add 0.8g TbCl to a 100ml three-neck flask 3 .6H 2 O and 40ml alcohol as solvent, sonicated to TbCl 3 .6H 2 O is completely dissolved, and hexa(4-formyl...

Embodiment 2

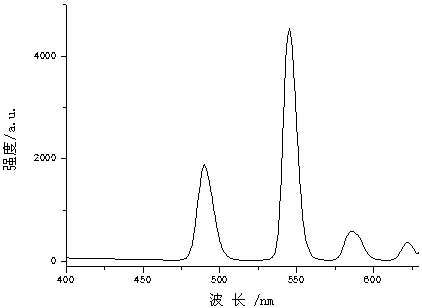

[0036] Example 2: The preparation method of tripolyphosphazene cross-linked rare earth complex luminescent material:

[0037] S1: In a 250ml single-necked flask, add 100ml of tetrahydrofuran in turn, 2.50g (7.19mmol) of hexachlorocyclotrimeric phosphazene, 7.13g (51.59mmol) of p-hydroxybenzoic acid, and 11.3g of potassium carbonate (82.30mmol), at 66 o C under heating and stirring, condensed and refluxed for 48h.

[0038] S2: After the reaction is complete, change to a distillation device, distill off the solvent tetrahydrofuran, then dissolve the product with DMF, and stir for 12 hours. After filtration, a clear filtrate was obtained. After half of the filtrate was evaporated, the product was finally reprecipitated with ethyl acetate, washed three times with ethyl acetate, and dried in vacuo for 15 hours.

[0039] S3: Add 0.8g EuCl to a 100ml three-neck flask 3 .6H 2 O, 40ml alcohol as solvent, sonicated to EuCl3 .6H 2 O is completely dissolved, and hexa(4-formyl potassiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com