Pigment violet 19 dispersion and preparation method thereof

A technology of pigment violet and dispersion, applied in the direction of pigment slurry, etc., can solve problems such as poor water solubility, and achieve the effects of good color stability, improved color stability, and improved application performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

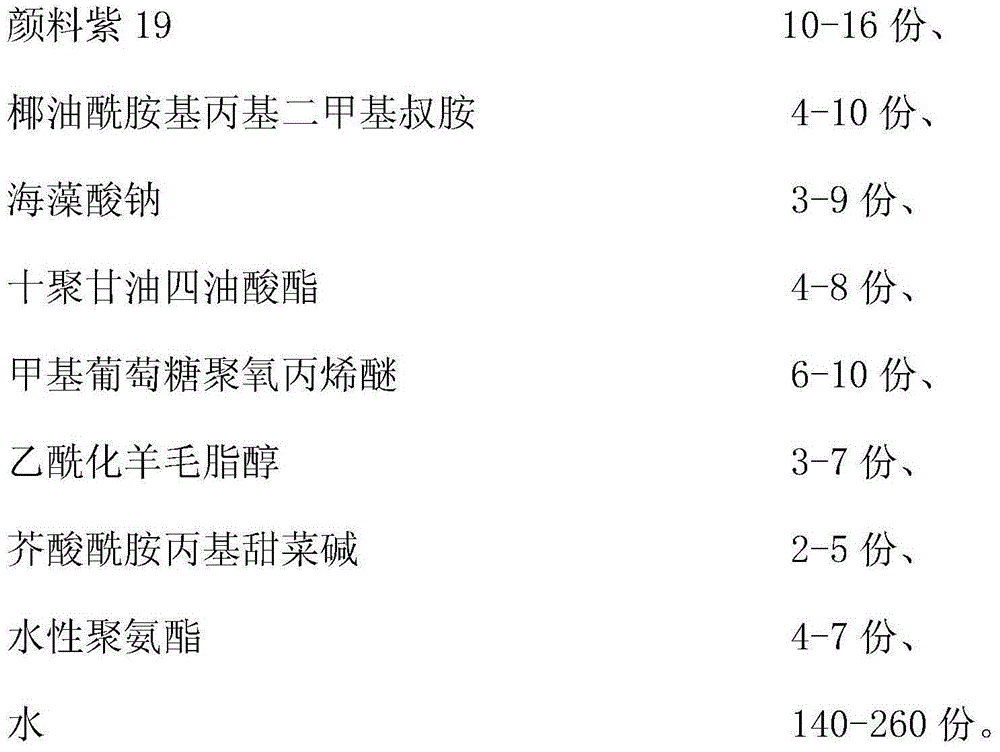

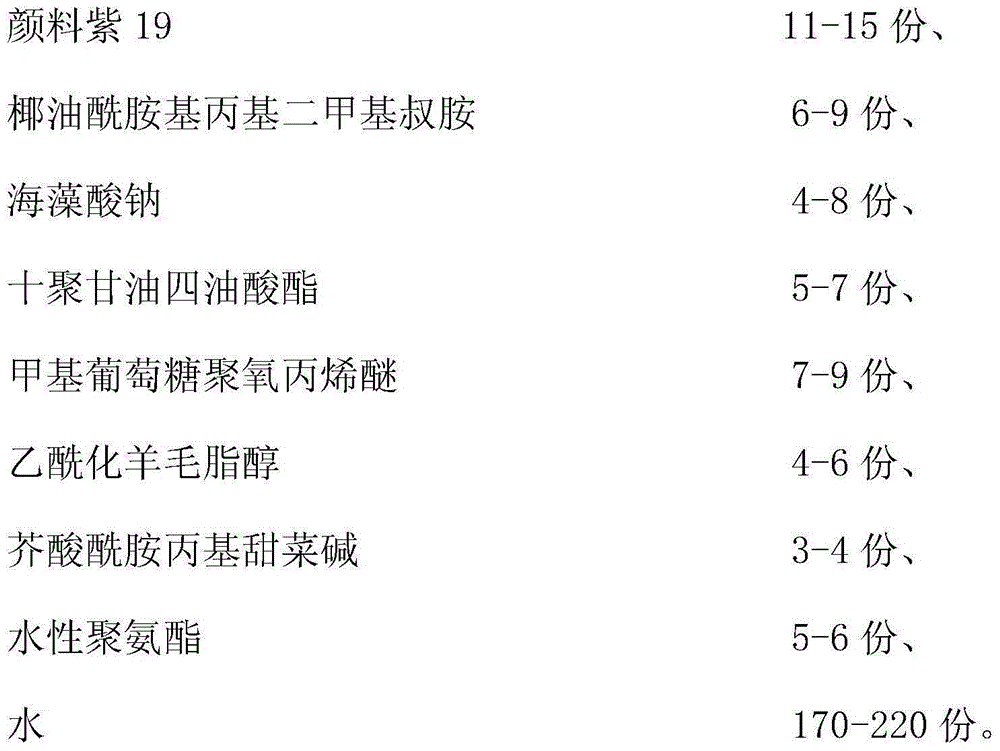

Method used

Image

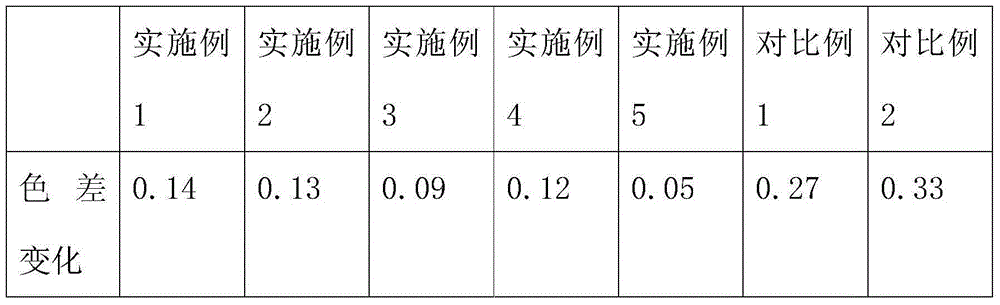

Examples

Embodiment 1

[0017] (1) Take respectively 16 parts of Pigment Violet 19, 4 parts of cocamidopropyl dimethyl tertiary amine, 9 parts of sodium alginate and 8 parts of decaglycerol tetraoleate by weight. The ingredients are stirred at room temperature, and after stirring evenly, it becomes the mixture A, which is set aside;

[0018] (2) Get 6 parts of methyl glucose polyoxypropylene ethers, 3 parts of acetylated lanolin alcohols, 5 parts of erucamide propyl betaines, 7 parts of water-based polyurethanes, and 260 parts of water respectively by weight, and put the above-mentioned ingredients in Stir at room temperature until uniform, it is mixture B, set aside;

[0019] (3) Mix mixture A and mixture B until uniform at a temperature of 40°C, and then shear the mixture with a shearing device at a shearing speed of 7000 rpm and a shearing time of 10 minutes. After shearing, It is pigment violet 19 dispersion.

Embodiment 2

[0021] (1) Take respectively 10 parts of Pigment Violet 19, 10 parts of cocamidopropyl dimethyl tertiary amine, 3 parts of sodium alginate, and 4 parts of decaglycerol tetraoleate by weight. The ingredients are stirred at room temperature, and after stirring evenly, it becomes the mixture A, which is set aside;

[0022] (2) Get 10 parts of methyl glucose polyoxypropylene ether, 7 parts of acetylated lanolin alcohol, 2 parts of erucamide propyl betaine, 4 parts of water-based polyurethane, and 140 parts of water respectively by weight, and put the above-mentioned ingredients in Stir at room temperature until uniform, it is mixture B, set aside;

[0023] (3) Mix mixture A and mixture B until uniform at a temperature of 50°C, then shear the mixture with a shearing device, the shearing speed is 4000rpm, and the shearing time is 60min. After shearing, It is pigment violet 19 dispersion.

Embodiment 3

[0025] (1) Take respectively 15 parts of Pigment Violet 19, 6 parts of cocamidopropyl dimethyl tertiary amine, 8 parts of sodium alginate and 7 parts of decaglycerol tetraoleate by weight. The ingredients are stirred at room temperature, and after stirring evenly, it becomes the mixture A, which is set aside;

[0026] (2) Get 9 parts of methyl glucose polyoxypropylene ethers, 4 parts of acetylated lanolin alcohols, 3 parts of erucamide propyl betaines, 6 parts of water-based polyurethanes, and 170 parts of water respectively by weight, and put the above-mentioned ingredients in Stir at room temperature until uniform, it is mixture B, set aside;

[0027] (3) Mix mixture A and mixture B at a temperature of 40°C until uniform, then shear the mixture with a shearing device, the shearing speed is 5000rpm, and the shearing time is 30min. After shearing, It is pigment violet 19 dispersion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com