U-PVC plastic, pipe fitting made of U-PVC plastic and preparing method of pipe fitting

A technology of rigid polyvinyl chloride and plastic pipe fittings, applied in the field of rigid polyvinyl chloride (U-PVC) plastic and its pipe fittings and production, can solve the problems of influence, unfavorable product performance, poor environment and human health, etc. Improve overall quality, reduce dosage, and improve the effect of processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

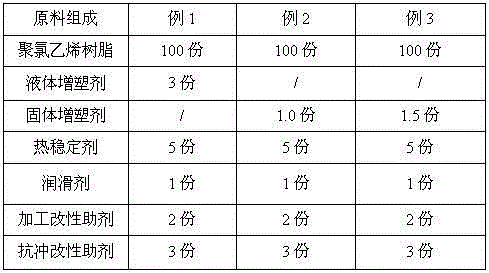

[0041] 1. The raw material components of rigid polyvinyl chloride plastic pipe fittings that do not contain o-phthalic solid plasticizers are selected and accurately weighed according to the three formulas in Table 1. Wherein, the solid plasticizer is a compound formed by the copolymerization reaction of polyether and alcohol ester, or one or more mixtures of complex ester compounds.

[0042] The polyvinyl chloride resin is prepared by a suspension method, the residual amount of vinyl chloride monomer in the polyvinyl chloride resin is less than 1.0 mg / kg, and the viscosity of the polyvinyl chloride resin is 50ml / g-110ml / g.

[0043] The heat stabilizer is an environment-friendly calcium-zinc stabilizer; further preferably, the stabilizer is an environment-friendly powdery or granular composite calcium-zinc stabilizer, and the mass percentages of calcium and zinc in the stabilizer are less than 1.5%.

[0044] The processing modification aid is one or a mixture of methyl methac...

Embodiment 2

[0056] The research of embodiment 2 rigid polyvinyl chloride plastic pipe fitting formula

[0057] 1. Effect of solid plasticizer content on rigid PVC plastic pipe fittings

[0058] (1) Prepare U-PVC plastic pipe fittings according to the production method described in Example 1 according to the formula in Table 3.

[0059] Wherein, the polyvinyl chloride resin is prepared by a suspension method, the residual amount of vinyl chloride monomer in the polyvinyl chloride resin is less than 1.0 mg / kg, and the viscosity of the polyvinyl chloride resin is 50ml / g-110ml / g;

[0060] The product G-P20B of Zhongshan Gusheng Chemical Industry Co., Ltd. is a compound formed by the copolymerization reaction of polyether and alcohol ester.

[0061] The thermal stabilizer is an environment-friendly composite calcium-zinc stabilizer, and the mass percentages of calcium and zinc in the stabilizer are all less than 1.5%;

[0062] The processing modification aid is a methyl methacrylate copoly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com