Shock absorbing rubber material used for transformer

A technology for damping rubber and rubber materials, applied in the field of rubber materials, to achieve the effects of excellent mechanical properties, wide damping temperature range and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

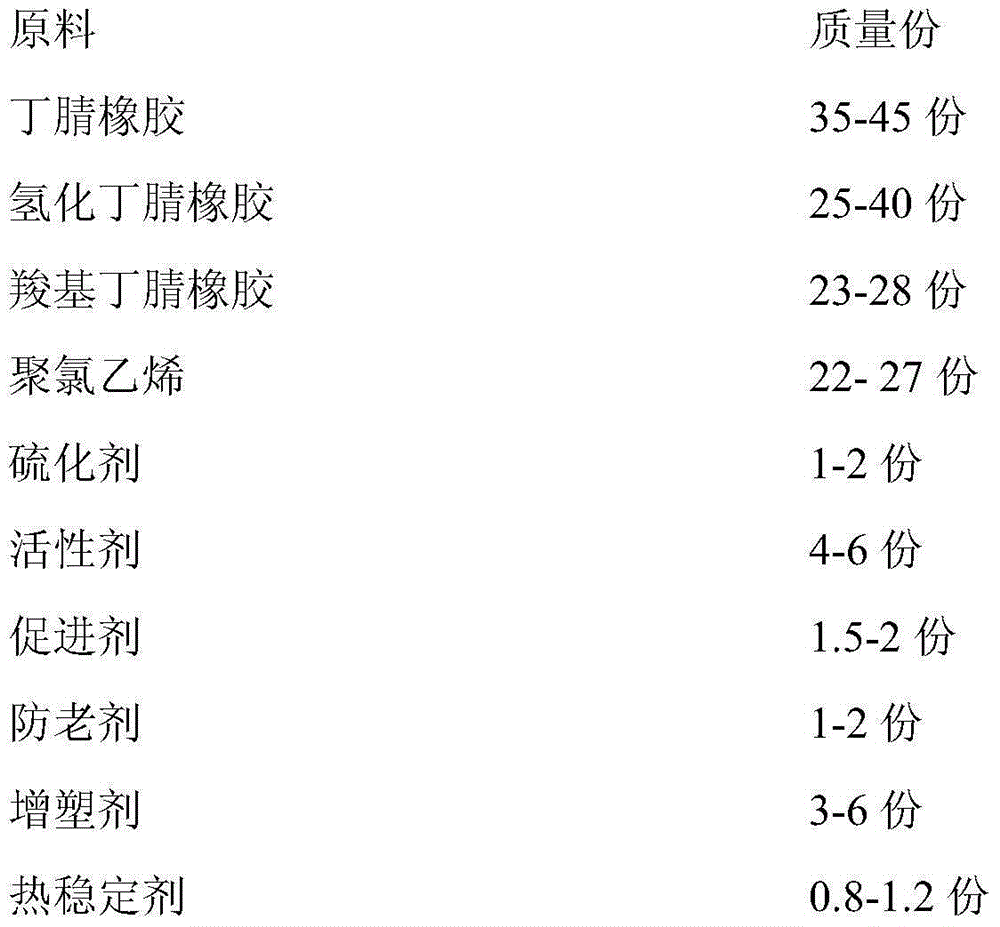

[0055] The raw materials for the preparation of shock-absorbing rubber include the following components in parts by mass:

[0056]

[0057]

[0058] The preparation process of the rubber material is as follows:

[0059] a) PVC pre-swelling

[0060] Mix polyvinyl chloride, heat stabilizer and plasticizer and stir at 65°C for 25 minutes to obtain a fully moistened polyvinyl chloride masterbatch;

[0061] b) plasticizing the Pengrun polyvinyl chloride masterbatch made in step a)

[0062] The masterbatch is plasticized to polyvinyl chloride with an open mill at a temperature of 155° C. for 2 minutes;

[0063] c) After adding nitrile rubber and anti-aging agent to the open mill of step b), kneading at 155° C. for 2 minutes under a pressure of 1 MPa;

[0064] d) Air-cool the blend obtained in step c) to room temperature, add hydrogenated nitrile butadiene rubber and carboxylated nitrile butadiene rubber into the open mill, add active agent, accelerator and reinforcing filler,...

Embodiment 2

[0067] The raw materials for the preparation of shock-absorbing rubber include the following components in parts by mass:

[0068]

[0069]

[0070] The preparation process of the rubber material is as follows:

[0071] a) PVC pre-swelling

[0072] Mix polyvinyl chloride, heat stabilizer and plasticizer and stir at 70°C for 30 minutes to obtain a fully moistened polyvinyl chloride masterbatch;

[0073] b) plasticizing the Pengrun polyvinyl chloride masterbatch made in step a)

[0074] The masterbatch is plasticized to polyvinyl chloride with an open mill at a temperature of 160°C for 3 minutes;

[0075] c) after adding nitrile rubber and anti-aging agent to the open mill of step b), at 160 ° C, mixing under 1 MPa pressure for 3 min;

[0076] d) Air-cool the blend obtained in step c) to room temperature, add hydrogenated nitrile butadiene rubber and carboxylated nitrile butadiene rubber into the open mill, add active agent, accelerator and reinforcing filler, and final...

Embodiment 3

[0079] The raw materials for the preparation of shock-absorbing rubber include the following components in parts by mass:

[0080]

[0081]

[0082] The preparation process of the rubber material is as follows:

[0083] a) PVC pre-swelling

[0084] Mix polyvinyl chloride, heat stabilizer and plasticizer and stir at 75°C for 35 minutes to obtain a fully moistened polyvinyl chloride masterbatch;

[0085] b) plasticizing the Pengrun polyvinyl chloride masterbatch made in step a)

[0086] The masterbatch was plasticized to polyvinyl chloride with an open mill at a temperature of 165°C for 4 minutes;

[0087] c) After adding nitrile rubber and anti-aging agent to the open mill of step b), kneading at 165 ° C for 4 min under a pressure of 1 MPa;

[0088] d) Air-cool the blend obtained in step c) to room temperature, add hydrogenated nitrile butadiene rubber and carboxylated nitrile butadiene rubber into the open mill, add active agent, accelerator and reinforcing filler, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com