A kind of polystyrene vinyl benzoate and its synthetic method and application

A technology of polystyrene vinyl benzoate and vinyl benzoate, applied in the field of polystyrene vinyl benzoate and its synthesis, can solve the problems of no effective monitoring method for oil production, etc. Achieve the effect of using less

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

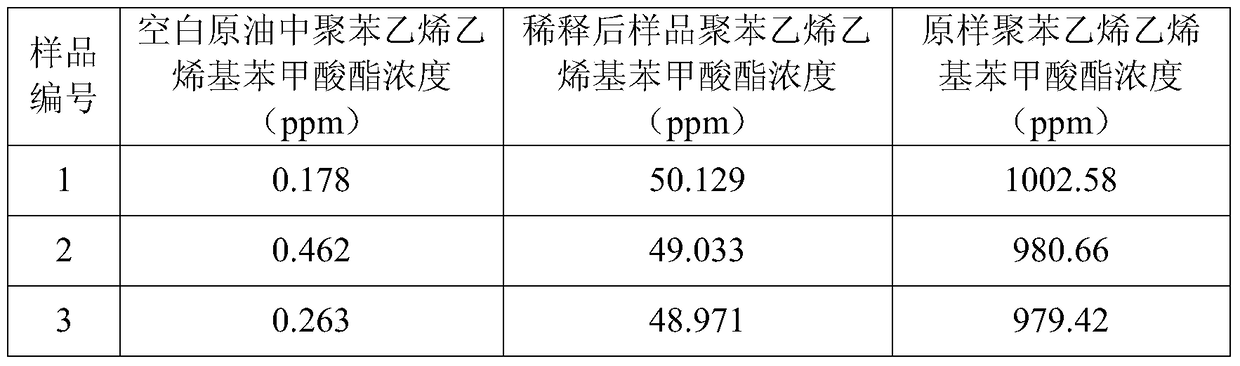

Embodiment 1

[0031] Dissolve 0.1g of polyethylene glycol (PEG4000 average molecular weight 3600-4400) into 50g of hot water, raise the temperature to 65°C for 30min, slowly add 45g of vinyl benzoate, 4.5g of styrene and 0.9g of azo The mixed solution of diisobutyronitrile was reacted for 8 hours after the dropwise addition, cooled to room temperature and discharged.

Embodiment 2

[0033] Dissolve 0.15g of polyethylene glycol (PEG4000 average molecular weight 3600-4400) into 60g of hot water, raise the temperature to 65°C for 30min, slowly add 35g of vinyl benzoate, 3.5g of styrene and 0.65g of azo The mixed solution of diisobutyronitrile was reacted for 8 hours after the dropwise addition, cooled to room temperature and discharged.

Embodiment 3

[0035] Dissolve 0.2g of polyethylene glycol (PEG4000 average molecular weight 3600-4400) into 70g of hot water, raise the temperature to 65°C for 30min, slowly add 25g of vinyl benzoate, 2.5g of styrene and 0.35g of azo The mixed solution of diisobutyronitrile was reacted for 8 hours after the dropwise addition, cooled to room temperature and discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com