Device and method for positioning moving workpiece

A workpiece and motion technology, applied in the field of positioning devices for workpieces in motion, can solve problems such as weak adaptability and low positioning accuracy, and achieve the effects of high work efficiency, high-precision positioning, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

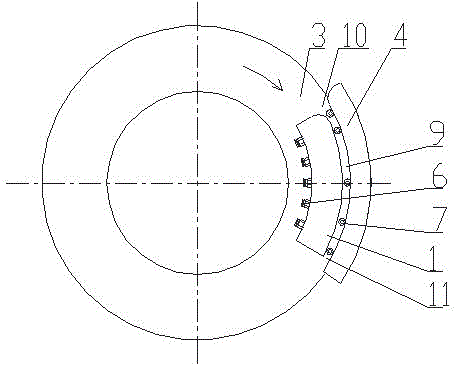

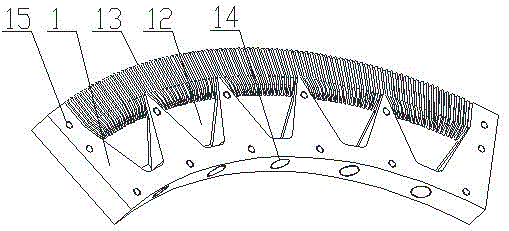

[0024] See figure 1 , figure 2 and image 3 as shown, figure 1 , figure 2 and image 3 Shown is the workpiece positioning method in motion of the present invention, including air knife main body 1, air knife cover 2, moving base plate 3, positioning block 4, pneumatic joint 6; air knife main body 1 and positioning block 4 are fixed, and moving base plate 3 is It is circular and rotates around its vertical center axis. An arc-shaped workpiece channel 9 is formed between the air knife main body 1 and the positioning block 4. The width of the workpiece channel 9 is greater than the maximum dimension of the workpiece 7 in the vertical projection direction. The workpiece channel 9 is two The ends are the workpiece channel inlet 11 and the workpiece channel outlet 12 respectively. There are air cavity 12, air hole array 13, air joint screw hole 14 and air knife cover screw hole 15 on the air knife main body 1, and the air knife cover 2 passes through the air knife cover screw ...

example 2

[0028] Instance 2 please refer to Figure 4 and Figure 5 As shown, the second example is a variant of the first example, which is basically the same as Figure 1~Figure 3 The specific embodiments shown are the same, and the same components use the same reference numerals. Compared with Example 1, the second example adds a pneumatic joint 8 and a positioning block bottom plate 5, and the positioning block bottom plate 5 is fixed on the positioning block 4. The pneumatic joint 8 is installed on the positioning block 4; the structure of the positioning block 4 is similar to that of the air knife main body 1, and also has an air hole array and an air cavity,

[0029] When working, the pneumatic joint 8 is connected to the external vacuum pump so that the air can be sucked away from the workpiece channel 9 to form a negative pressure on the side of the workpiece channel 9 close to the positioning block 4. This negative pressure acts alone or with the airflow from the air knife ma...

example 3

[0031] For example three, please refer to Figure 6 As shown, the third example is a variant of the first example, which is basically the same as Figure 1~Figure 3 The specific embodiments shown are the same, and the same components use the same reference numerals. Compared with Example 1, Example 3 has five air cavities 12 in the air knife main body 1 of Example 1, and there are 5 air connector screw holes 14 correspondingly. , 5 pneumatic joints 6 are installed, so that each section of the air hole array 13 at different positions of the air knife main body 1 is adjustable to adjust the air pressure independently, and the example three has only one air chamber 12, and the air outlet of the air hole array 13 in the example three The air pressure is not adjustable in sections.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com