Automotive safety seat backrest

A technology for car safety seats and backrests, which is applied in the direction of seat belts, vehicle parts, belt fixing devices, etc. in the car, which can solve the problems of large impact force of airbags, limited protection, and insufficient active protection of seat belts to achieve safety. High performance and wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

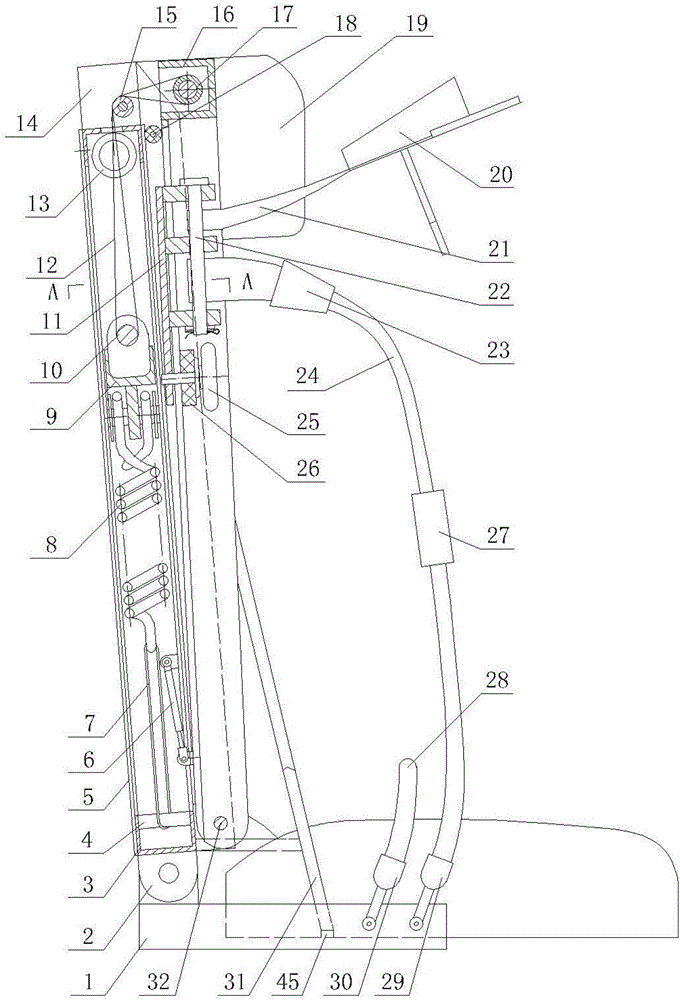

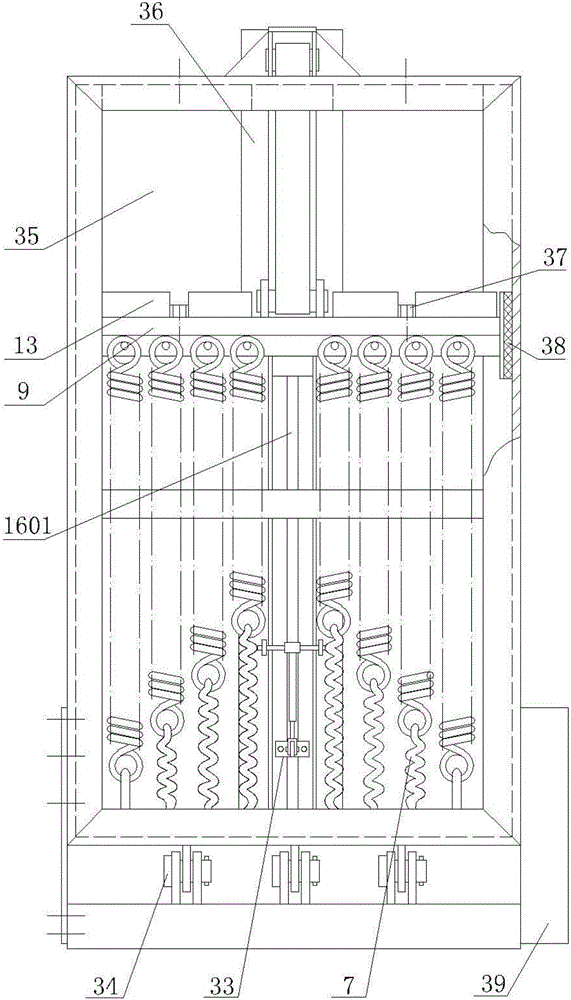

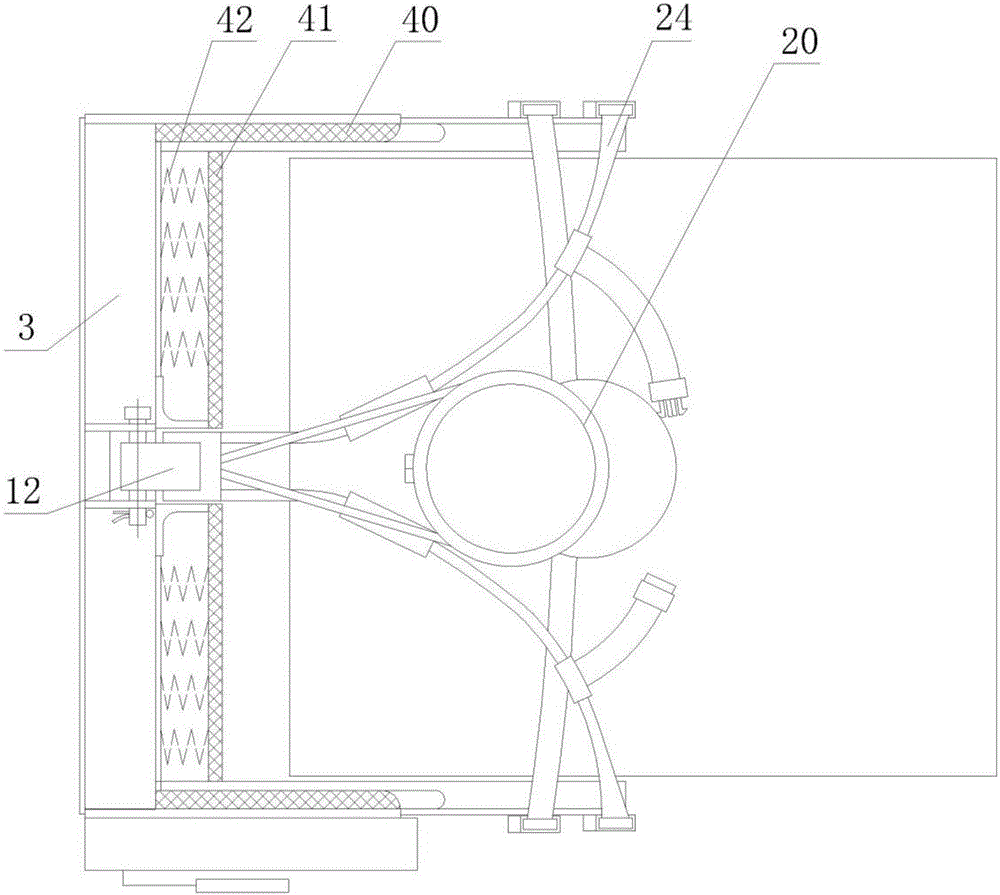

[0026] Such as Figure 1-Figure 4 As shown, the backrest of a car safety seat related to the present invention includes a backrest connecting seat 1 fixedly connected with the chassis of the car, and a backrest bracket 3 is connected to the backrest connecting seat 1 through an angle adjuster 39, and the backrest connecting seat 1 Three groups of hinged seats 2 corresponding to each other are respectively welded with the backrest bracket 3 . As preferably, triangular brackets 31 are symmetrically welded on both sides of the front of the backrest bracket 3, and the lower ends of the slanted beams of the triangular brackets 31 lean against the crossbeams on both sides of the backrest connection seat 1, and buffers are plugged in the lower ports of the slanted beams of the triangular brackets 31. Rubber pad 45.

[0027] The back support 3 includes a rectangular frame connected by channel steel, and a front panel 35 and a rear panel 5 are respectively fixed by screws on the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com