Mobile phone protection film with overheat/overcold protection and warning functions

A protective film, supercooling technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve problems such as increased power consumption, slower mobile phone operation, and limited heat dissipation performance, to prevent The effect of running slowly and preventing the mobile phone from running slowly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

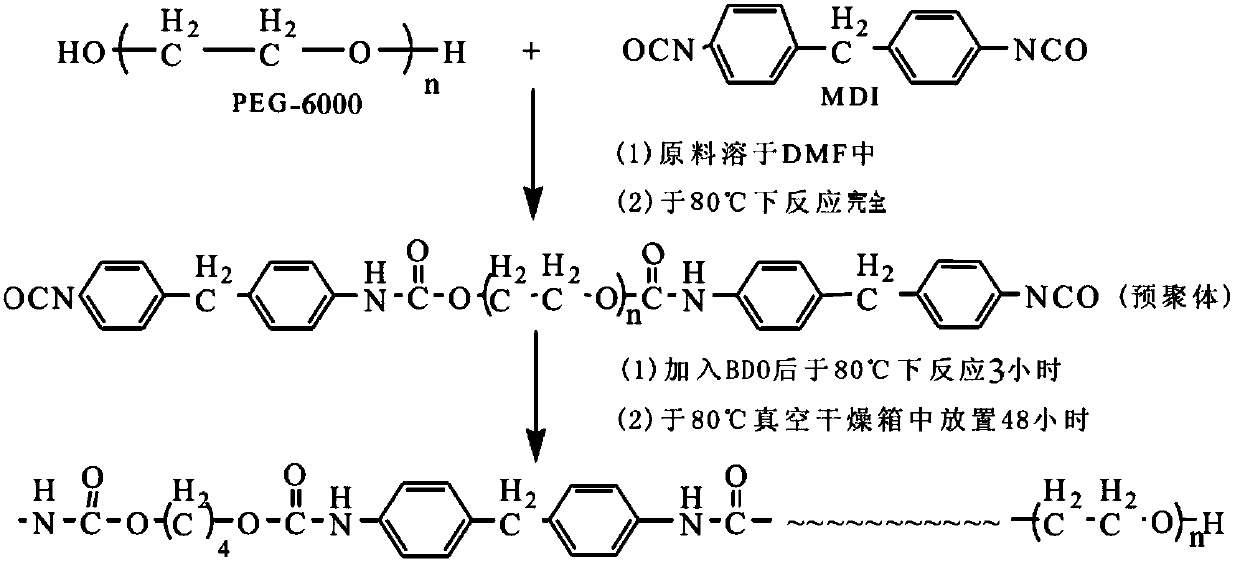

Method used

Image

Examples

Embodiment 1

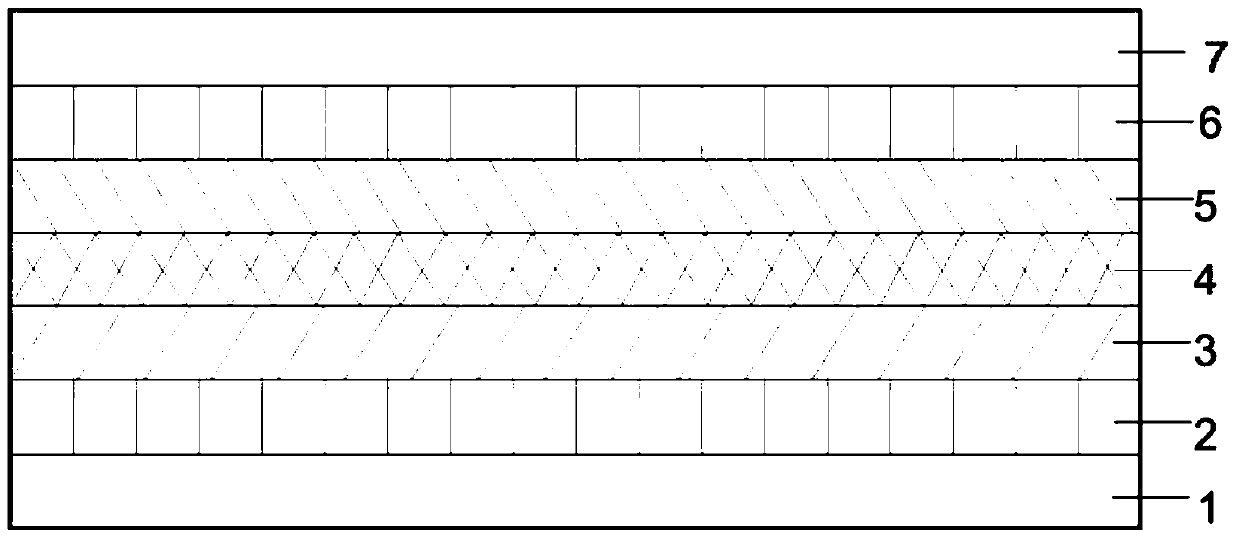

[0051] Such as figure 1 The mobile phone protective film shown is directly connected between two adjacent layers. The size and shape of the mobile phone protective film are determined according to the mobile phone model and screen size. The thickness of the first release layer is 30 μm, the thickness of the overheat protection layer is 20 μm, the thickness of the temperature-sensitive paint layer is 2 μm, the thickness of the transparent substrate layer is 50 μm, and the thickness of the second release layer is 30 μm.

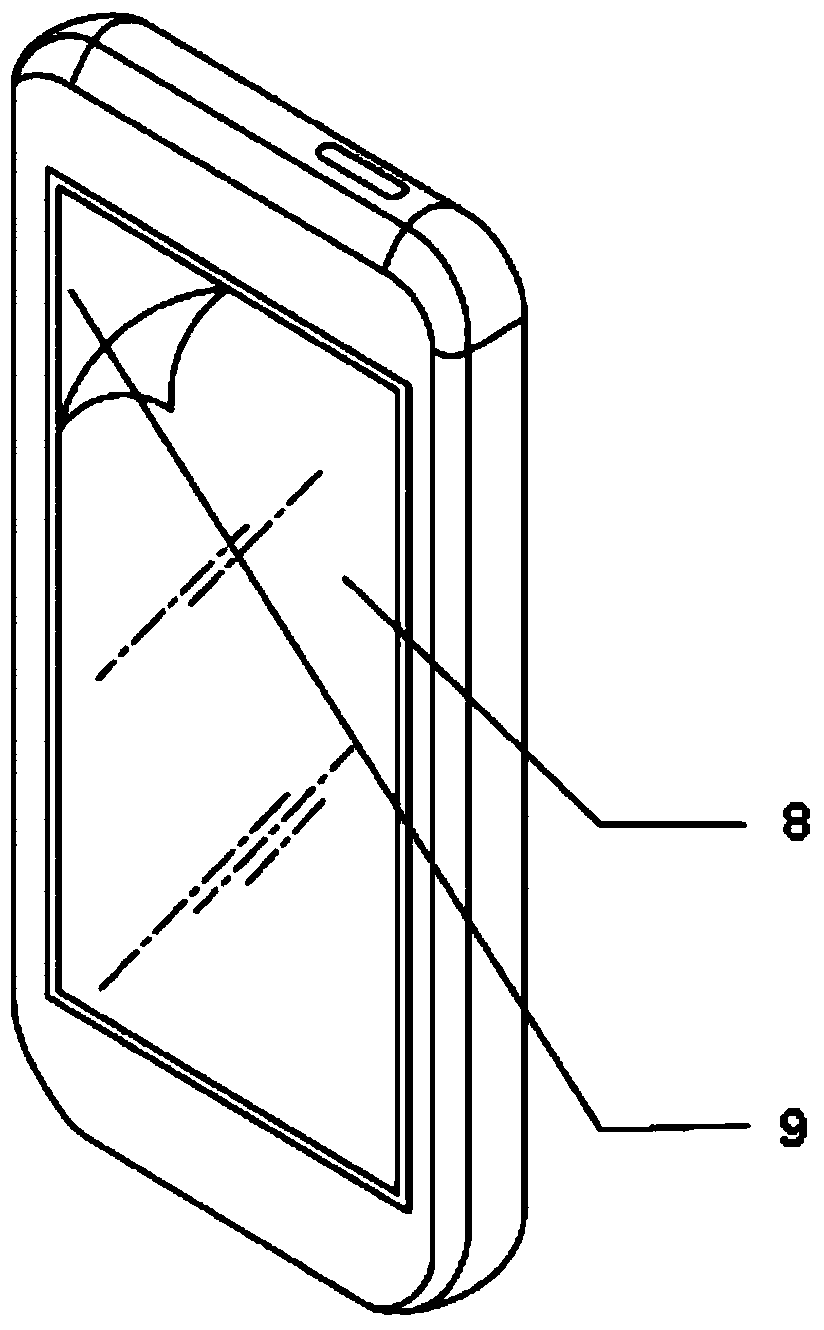

[0052] When sticking a film on the screen of a mobile phone, first wipe the screen clean to remove oil or moisture on the surface, and then remove the first release layer, such as figure 2 As shown, paste from the corner of the mobile phone, slowly compact the protective film with a thin plate, etc. to expel air bubbles, and finally peel off the second release layer on the upper layer from the second adhesive layer, and the film is completed.

[0053] The mob...

Embodiment 2

[0055] The shape of the mobile phone protective film is the same as that of Embodiment 1. The thickness of the first release layer is 10 μm, the thickness of the temperature-sensitive paint layer is 10 μm, the thickness of the overheat protection layer is 50 μm, the thickness of the transparent substrate layer is 20 μm, and the thickness of the second release layer is 60 μm.

[0056] The mobile phone film sticking method is the same as in Example 1.

[0057] The experimental method is the same as in Example 1. After running for 6 hours, the average temperature of the mobile phones in the experimental group is 44°C, the average temperature of the mobile phones in the control group is 51°C, and the average temperature of the blank group is 50°C. The test shows that the mobile phone protective film of the present invention can effectively Absorb the heat generated during the operation of the mobile phone.

Embodiment 3

[0059] The shape of the protective film of the mobile phone is the same as in Example 1. The thickness of the first release layer is 80 μm, the thickness of the temperature-sensitive paint layer is 30 μm, the thickness of the overheat protection layer is 10 μm, the thickness of the transparent substrate layer is 200 μm, and the thickness of the second release layer is 20 μm.

[0060] The mobile phone film sticking method is the same as in Example 1.

[0061] Set the temperature of the refrigerator to 0°C. After 1 hour of stabilization, place the mobile phone in the refrigerator, detect the temperature of the core of the mobile phone in real time, and take it out after 3 hours. The average temperature of the assembled mobile phone is 10°C. The test shows that the mobile phone protective film of the present invention can effectively absorb the heat generated during the operation of the mobile phone. It shows that the mobile phone protective film of the present invention can rel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com