Full-automatic casting method for continuous casting machine

A continuous casting machine, fully automatic technology, applied in the field of casting of continuous casting machines, can solve the problems of high failure rate of manual casting and unstable casting quality, so as to avoid sharp fluctuation of liquid level and eliminate casting marks , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to better explain the present invention, the main content of the present invention is further clarified below in conjunction with specific examples, but the content of the present invention is not limited to the following examples.

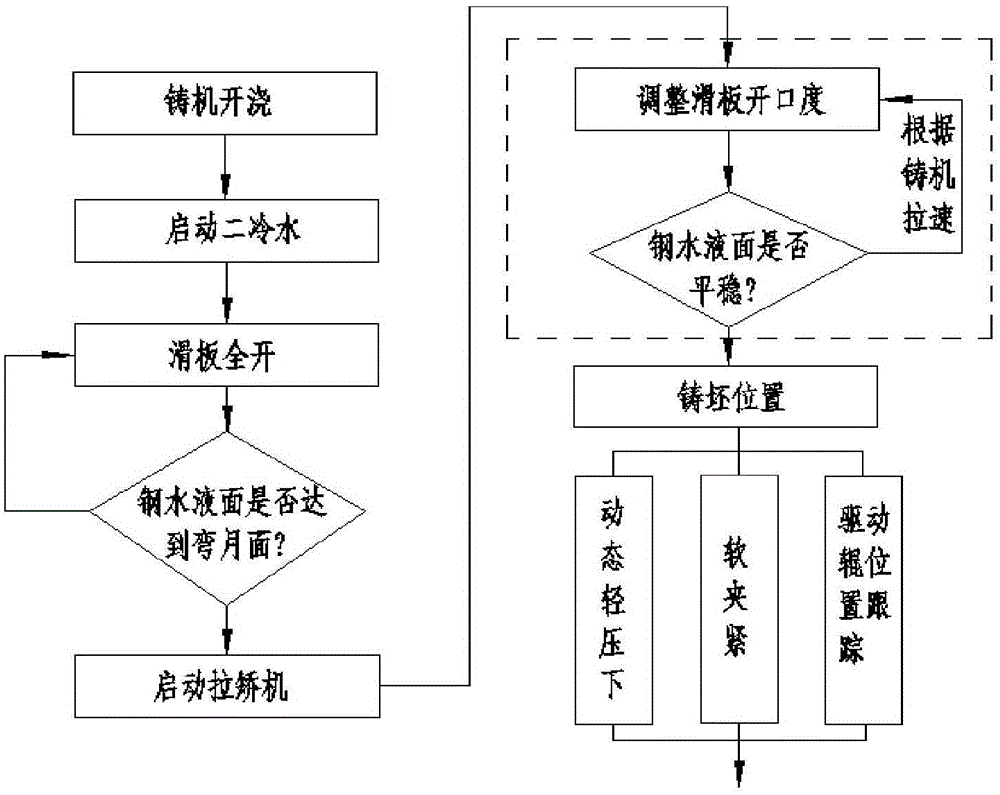

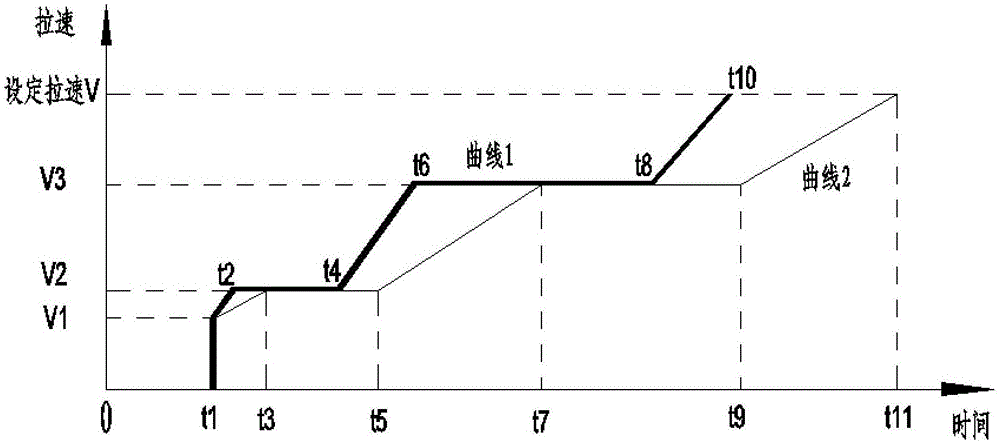

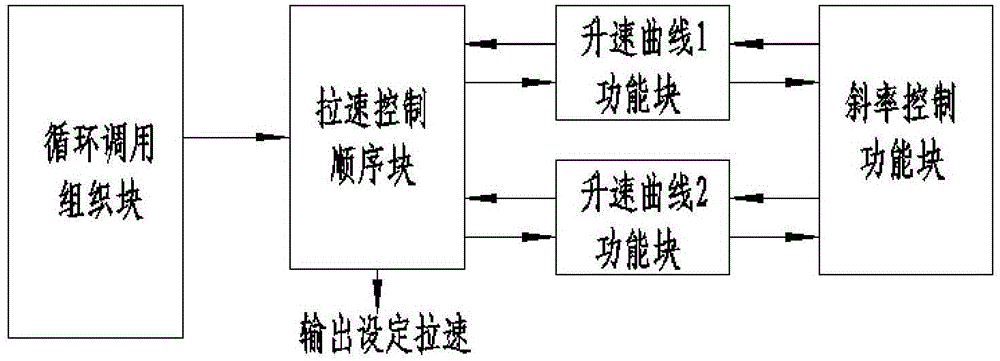

[0048] A method for fully automatic pouring of a continuous casting machine, comprising the following steps:

[0049] 1) When the continuous casting machine turns on the pouring mode, the continuous casting machine searches the data in the secondary cooling water database to match the secondary cooling water according to the steel type, width and molten steel temperature of the billet, and automatically starts the secondary cooling water of the system;

[0050] 2) After the secondary cooling water is started, the system fully opens the tundish slide plate through the hydraulic control valve, so that the molten steel quickly flows from the tundish into the mold, and simultaneously detects and calculates the distance between the mold li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com