A numerically controlled reinforcement machine

A technology of bar machine and steel bar, applied in the field of CNC bar machine, can solve the problems of low processing efficiency, high maintenance difficulty, poor safety, etc., and achieve the effects of reducing mechanical damage, high-precision straightening, and reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

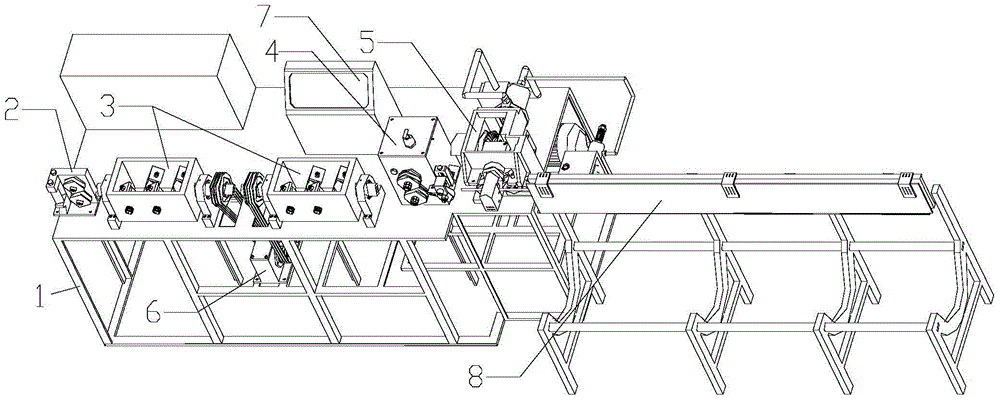

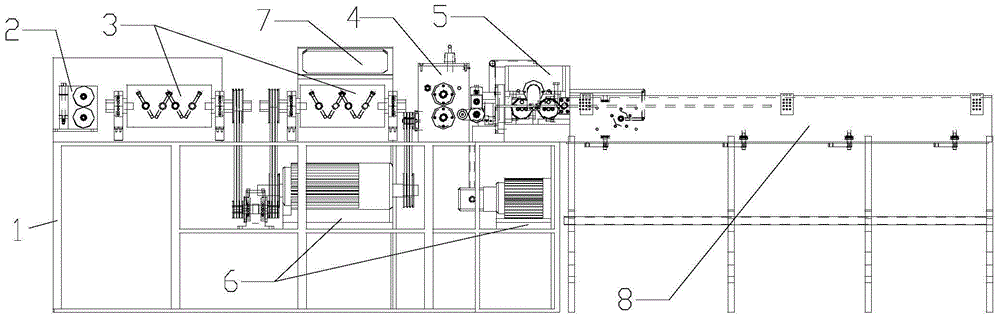

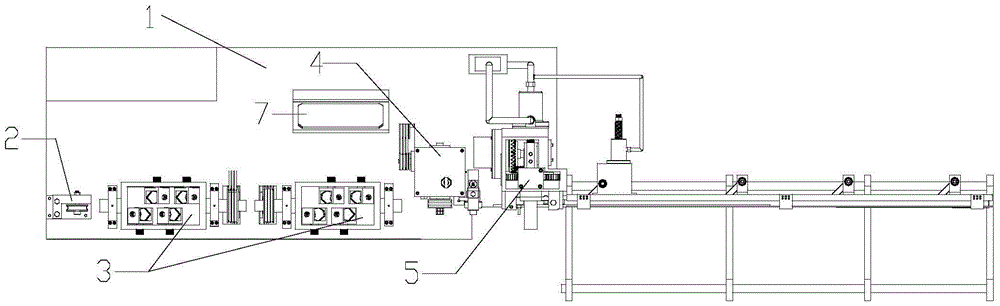

[0023] Please also refer to figure 1 , figure 2 as well as image 3 , as shown in the figure, it can be seen that a numerically controlled reinforcement machine of the present invention includes a frame 1, a steel bar guiding mechanism 2, a double centrifugal straightening mechanism 3, a traction mechanism 4, a hydraulic shearing double-head bending machine 5, a power mechanism 6, Electric control mechanism 7, limit and material support mechanism 8, steel bar guiding mechanism 2 is arranged at the front of the present invention, steel bar guiding mechanism 2, double centrifugal straightening mechanism 3, traction mechanism 4, hydraulic shearing double-head bending machine 5, and the position limiting and material supporting mechanism 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com