Precise small hole stamping mold of filtering plate

A technology for punching small holes and filter plates, applied in the field of punching dies and filter plates accurately punching small hole dies, can solve the problems of difficult operation, reduced production efficiency, short service life, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

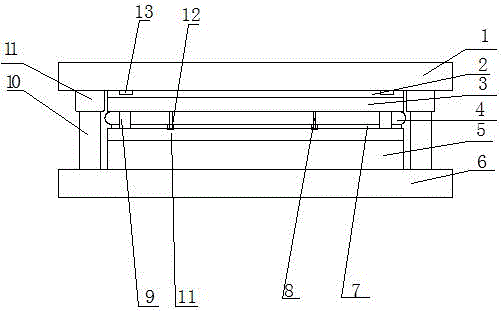

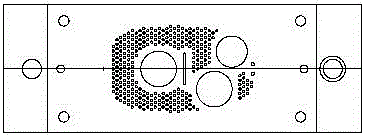

[0013] Such as figure 1 and figure 2 The precision punching small hole die for the filter plate shown includes an upper template 1 and a lower template 6, a guide sleeve 11 and an outer guide post 10 arranged between the upper template and the lower template, and a backing plate 2 arranged on the bottom surface of the upper template , and the punch fixing plate 3 arranged below the backing plate, and the unloading plate 7 connected to the lower punch fixing plate through the inner guide column 9, and the punch 8 arranged on the punch fixing plate, and the punch 8 arranged on the lower The die 5 on the template and the rubber 4 arranged between the punch fixing plate and the die are provided with a frame-shaped positioning frame 14 on the periphery of the discharge plate; the frame-shaped positioning frame 14 is movable through the guide column 9 and installed To the rear punch fixing plate 12; the discharge plate 7 is provided with a punch guide cylinder 12 movable around th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com