Rotary drill type ditching device capable of regulating space between ditches

A spacing and drilling technology, which is applied in the directions of planting methods, applications, excavation/covering trenches, etc., can solve the problems of time-consuming and laborious, inability to drill ponds, and low work efficiency, so as to improve work efficiency and improve the convenience of control , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

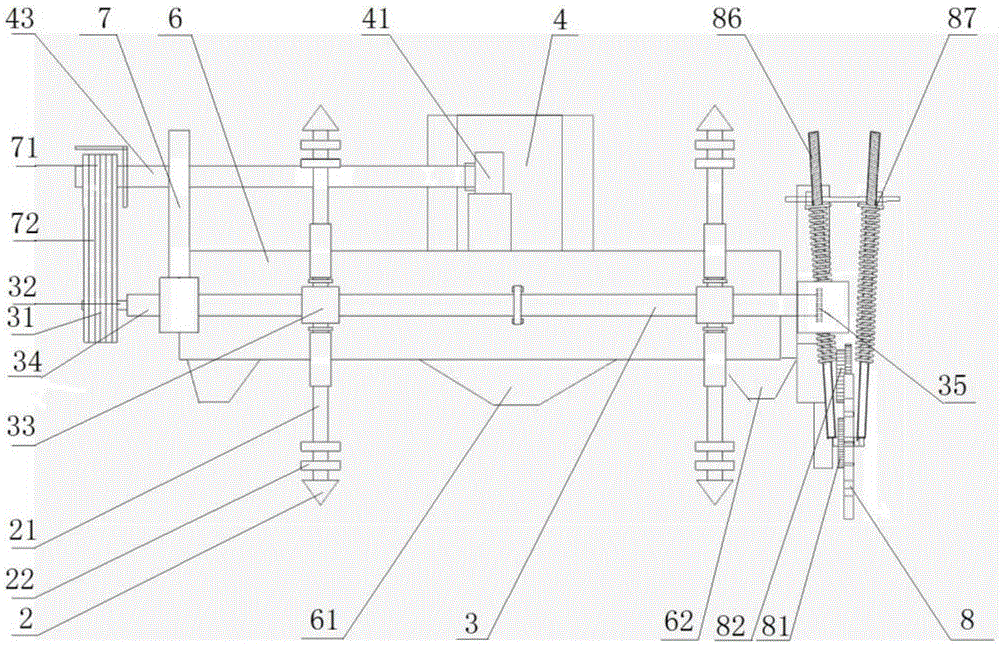

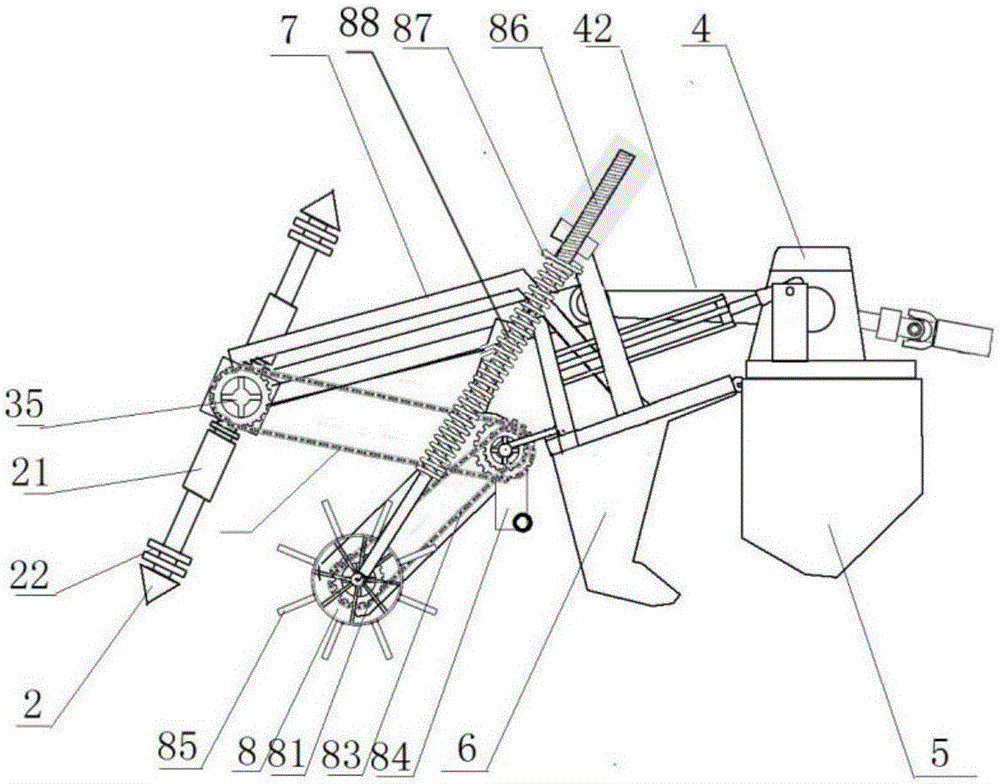

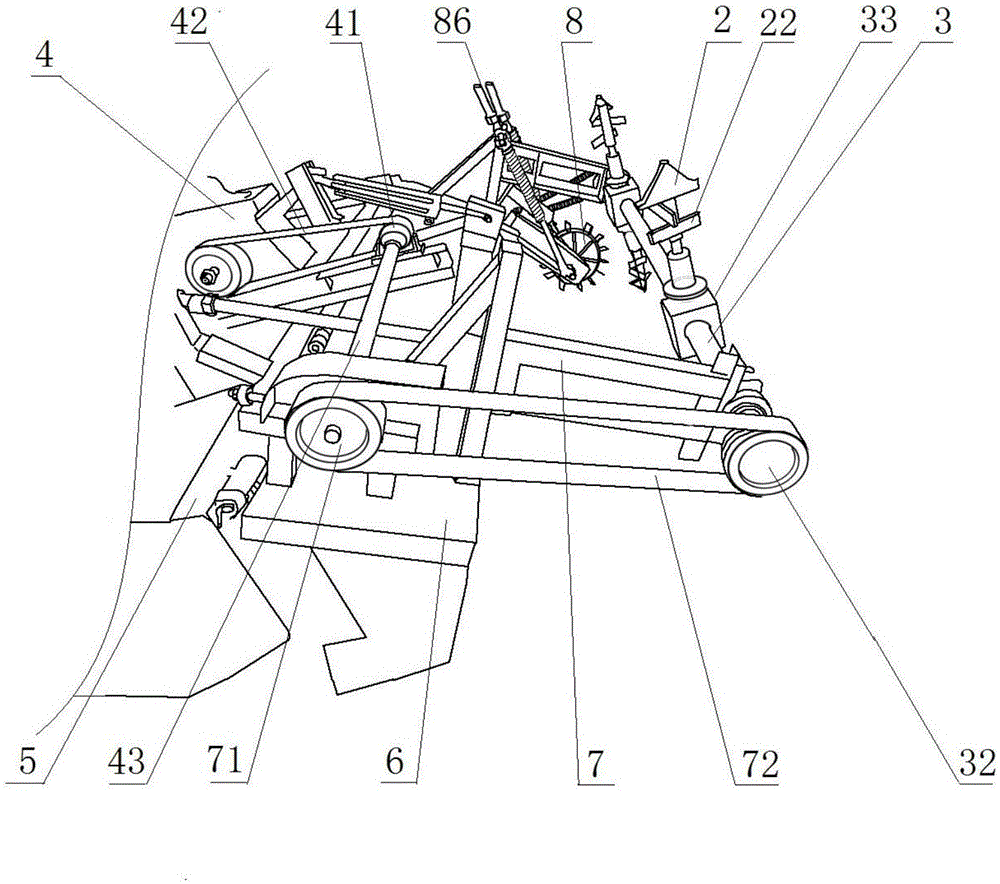

[0027] Implementation column 1: if Figure 1~3 As shown, a rotary drill type adjustable pond spacing device for making ponds, the engine provides power for the power device, the power device is connected to the rotary cultivator cone 4 through the transmission shaft, and the rotary tiller cone 4 is placed on the rear bracket 5 , the rotary cultivator tooth wheel 4 is connected to the front cross bar 3 placed on the front cross frame 6 through a transmission belt, and the front cross frame 6 is connected to the inner shaft drive wheel 32 of the front cross bar 3 through a connecting bracket 7. An inner shaft transmission gear box 33 is installed on the horizontal rotation rod 3, the drill pipe 21 is placed on the inner shaft transmission gear box 33, the drill bit 2 is placed on the top of the drill pipe 21, and the transmission inner shaft 31 is shifted by driving the inner shaft. The gear box 33 allows the drill rod 21 to rotate, and one end of the front cross frame 6 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com