Cell case

一种电池壳体、壳体的技术,应用在电池、二次电池、电池组零部件等方向,能够解决内部压力上升等问题,达到工作压力稳定化、操作容易、提高强度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0041] (The overall structure of the battery case)

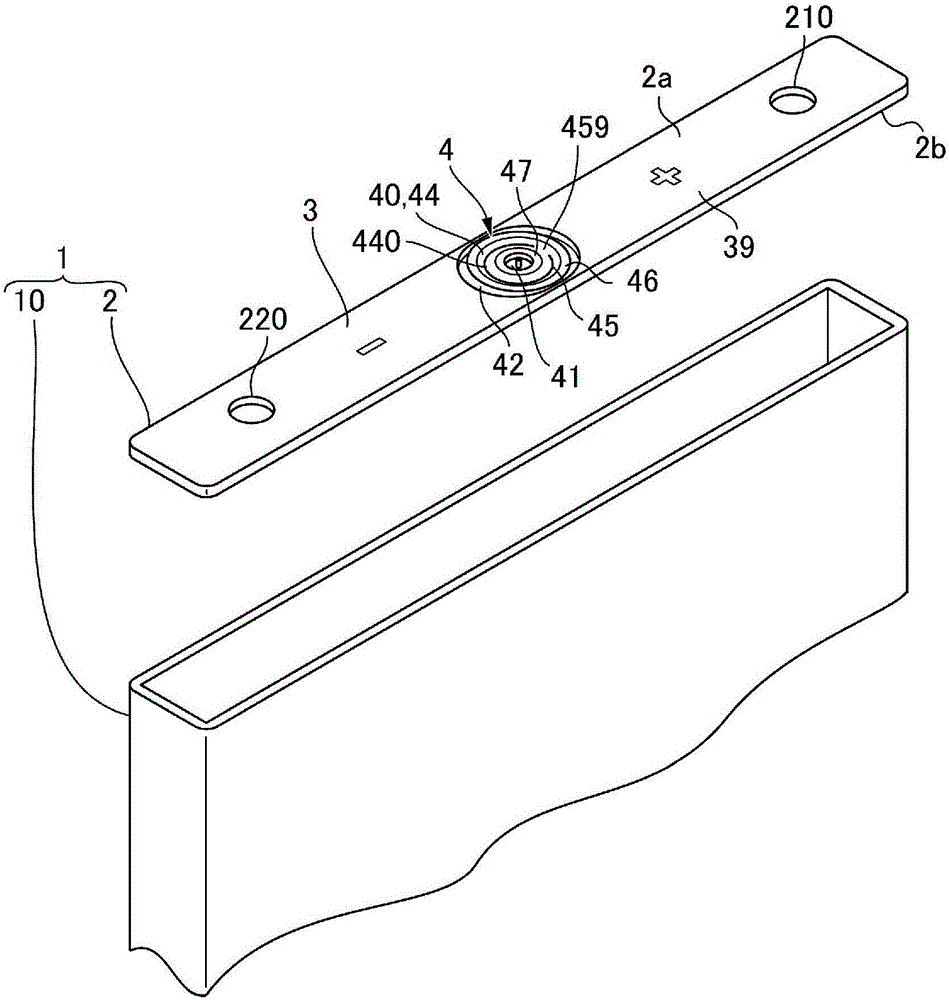

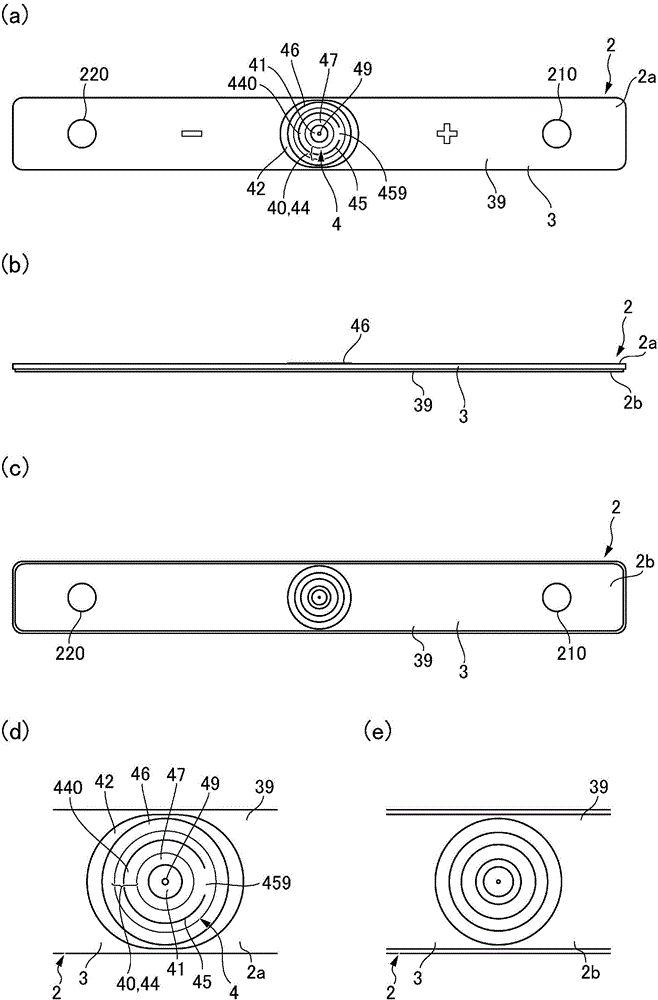

[0042] figure 1 It is a perspective view showing the appearance of the battery case 1 according to Embodiment 1 of the present invention, and shows how the battery case 1 is disassembled into a case main body 10 and a cover 2 .

[0043] Such as figure 1 As shown, the battery case 1 of this form has: a flat box-shaped case body 10 in the shape of a cuboid; and a plate-shaped cover 2 that closes the opening of the case body 10. Manufactured by processing such as metal plate pressurization. In this embodiment, both the case main body 10 and the cover 2 are manufactured by processing such as pressing an aluminum alloy plate material having a thickness of 0.3 mm to 3.0 mm. In addition, the case main body 10 and the cover 2 can also be manufactured by performing processing such as pressurization on other metal plate materials such as copper or iron.

[0044] Electrodes (not shown) for a secondary battery such as a lithium io...

Embodiment approach 2

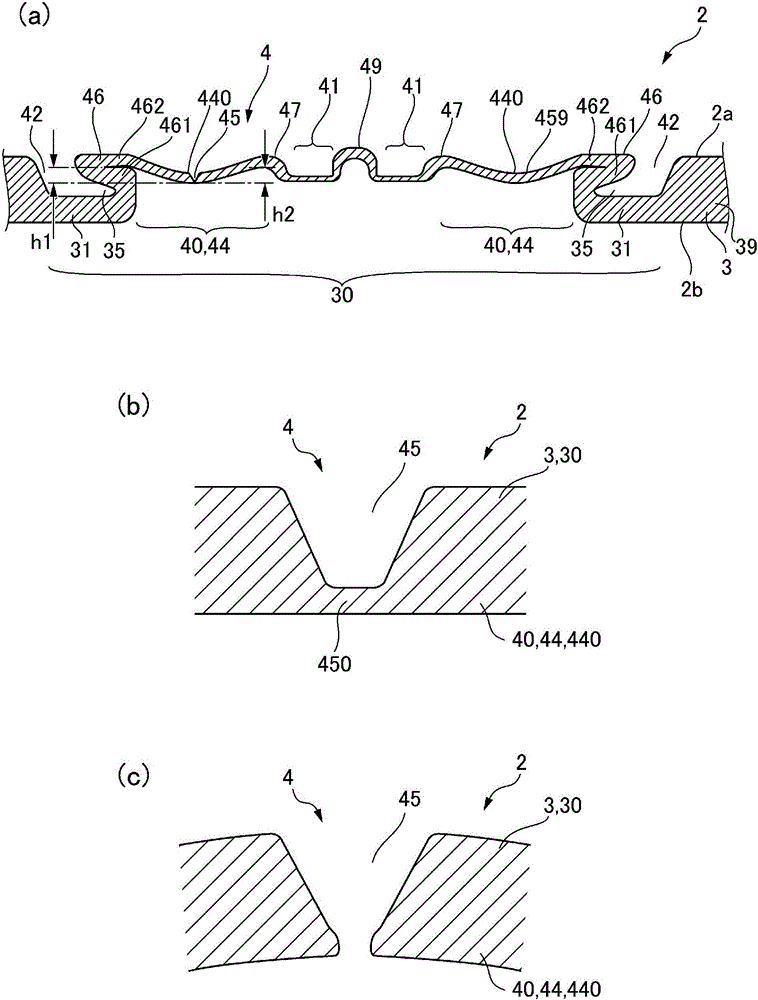

[0091] (Structure of battery case 1x and safety valve 4x)

[0092] Figure 8It is a perspective view showing the appearance of the battery case 1x according to Embodiment 2 of the present invention, and shows how the battery case 1x is disassembled into a case main body 10 and a cover 2 . Figure 9 It is explanatory drawing of the cover 2 of the battery case 1x in Embodiment 2 of this invention, Figure 9 (a), (b) are the plan view of the cover 2, and the enlarged plan view of the safety valve 4x formed in the cover 2, respectively. Figure 10 is a cross-sectional view of the safety valve 4x of the battery case 1x according to Embodiment 2 of the present invention, Figure 10 (a), (b), (c) are respectively Figure 9 (b) A-A' sectional view, BB' sectional view and CC' sectional view. In addition, since the battery case 1x of this embodiment has the same basic structure as the battery case 1 of Embodiment 1, the same code|symbol is attached|subjected to a common part, and de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com