Wafer dewaxing device and dewaxing method

A wafer and dewaxing technology, applied in the manufacture of electrical components, electric solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of energy waste, waste of manpower, etc., to reduce labor intensity, facilitate operation, and facilitate installation and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

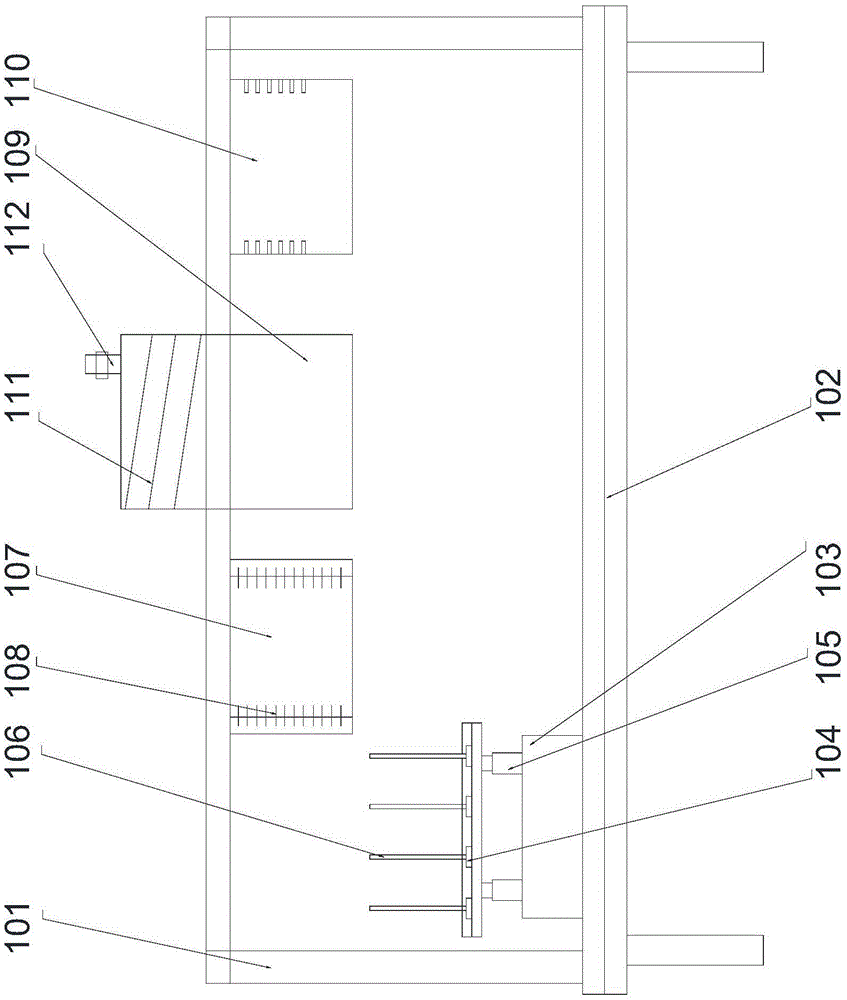

[0033] In order to collect wax conveniently, in this embodiment, preferably, a dust removal device is provided at the end of the exhaust port at the upper end of the high-temperature gasification box 107 .

[0034] Further preferably, the dust removal device includes a condensation plate 111 connected to the exhaust port and a dust removal exhaust port 112 arranged on the upper part of the condensation plate 111 . By adopting the condensation plate, after the wax is vaporized at high temperature, it gathers on the condensation plate, which is convenient for centralized treatment.

[0035] In order to facilitate fixing the installation bar, in this embodiment, preferably, the installation groove 104 is a T-shaped slot, and the lower end of the installation bar 106 is clamped in the installation groove 104 .

[0036] Further preferably, a resistance wire is arranged inside the installation strip 106 . By arranging the resistance wire, the mounting bar can be heated, so that the...

Embodiment 2

[0039] An integrated wafer dewaxing method, comprising the following steps:

[0040] S1: install the chip: install the chip on the mounting bar 106, and snap the mounting bar 106 into the mounting groove (104), so that the mounting bar 106 is fixed relative to the mounting groove 104;

[0041] S2: Push the fixed plate 103 to move along the guide rail 102. When the fixed plate 103 reaches the bottom of the electromagnetic heating box 107, start the hydraulic cylinder 105 to push the installation groove 104 and the installation bar 106 to move up as a whole until the wafer is completely placed in the electromagnetic heating box 107 Inside, carry out electromagnetic heating to remove wax;

[0042] S3: after step S2, place the wafer in the high-temperature vaporization box 107, and vaporize the remaining wax on the wafer at high temperature;

[0043] S4: The wafers after step S3 are placed in the hot air drying box 110, and then output after hot air drying treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com