High-impedance transformer coil winding device and method

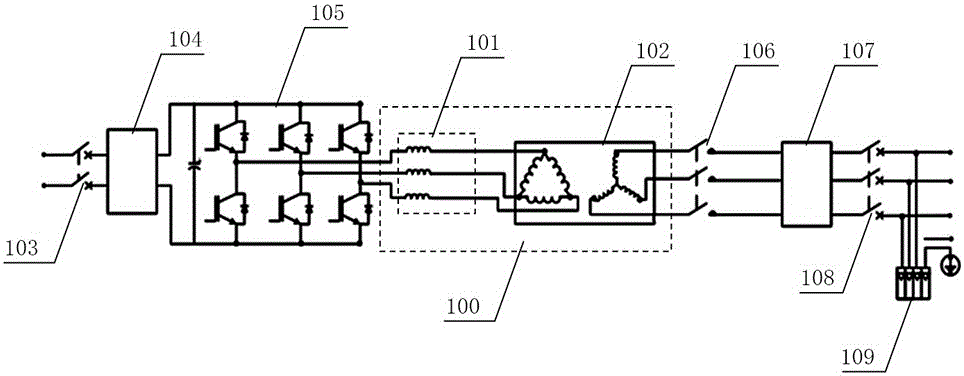

A technology of high-impedance transformers and winding methods, which is applied in the direction of coil manufacturing, etc., can solve problems such as waveform variation, noise increase, transformer stray loss, etc., and achieve the effects of simple components, cost saving, and improved winding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0063] A specific embodiment of a high-impedance transformer coil winding method utilizing the above-mentioned device, comprising the following steps:

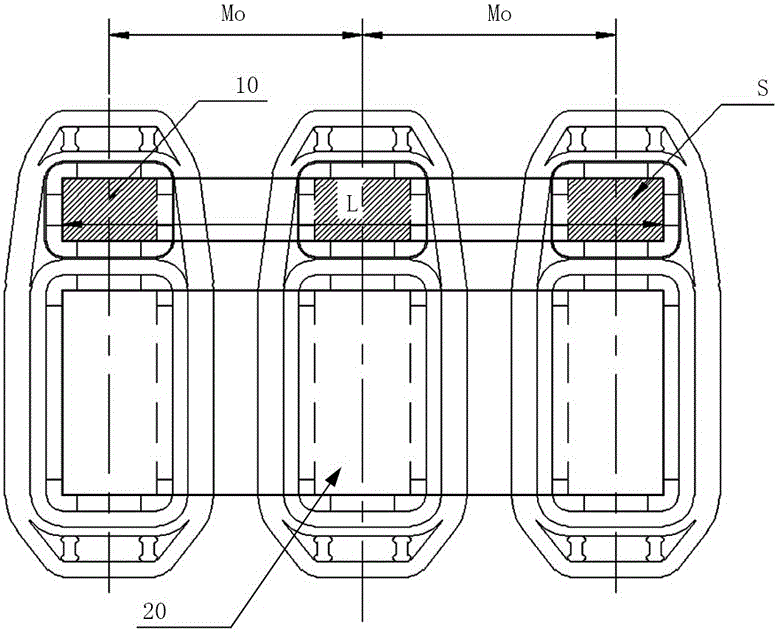

[0064] S100: Use bolts to fix the two splints 2 on the collet of the winding machine fixing plate 9 through the matching hole 6 of the winding machine fixing plate;

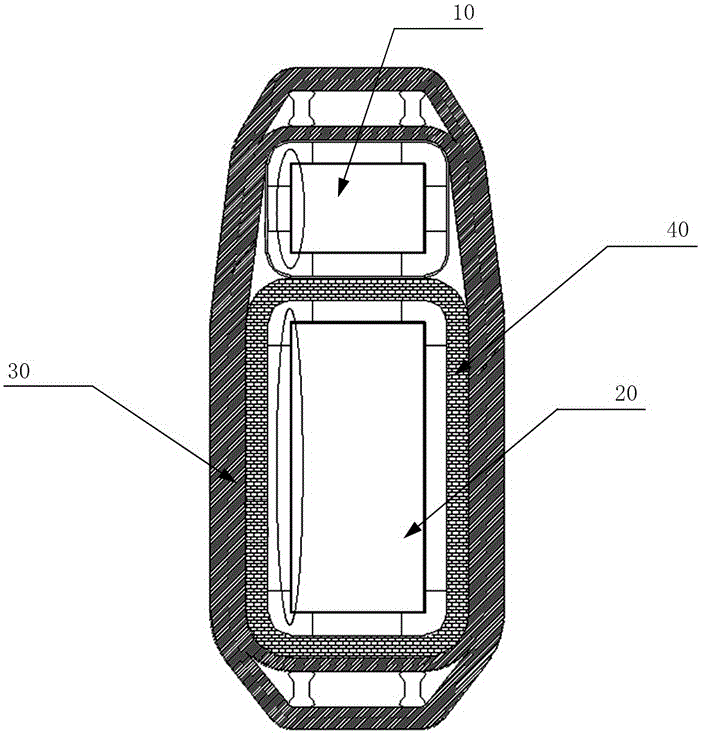

[0065] S101: Adjust the distance between the two splints 2 to be greater than the width of the laminations of the auxiliary iron core column 10 and the main iron core column 20; as a typical embodiment of the present invention, adjust the distance between the two splints 2 to be greater than The width of the laminations of the auxiliary iron core column 10 and the main iron core column 20 is 2 mm;

[0066] S102: Turn the winding machine so that the splint 2 is parallel to the ground, install two first stoppers 3, and make the distance between the two first stoppers 3 greater than the lamination thickness of the main core column 20;

[0067] S103: install the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com