Permeability testing method and device based on radial percolation experiment

A test method and permeability technology are applied in the field of permeability test methods and devices based on radial seepage experiments, which can solve the problems of high pressure oil easily invading media, experimental failure, and inaccurate coal body strain test.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

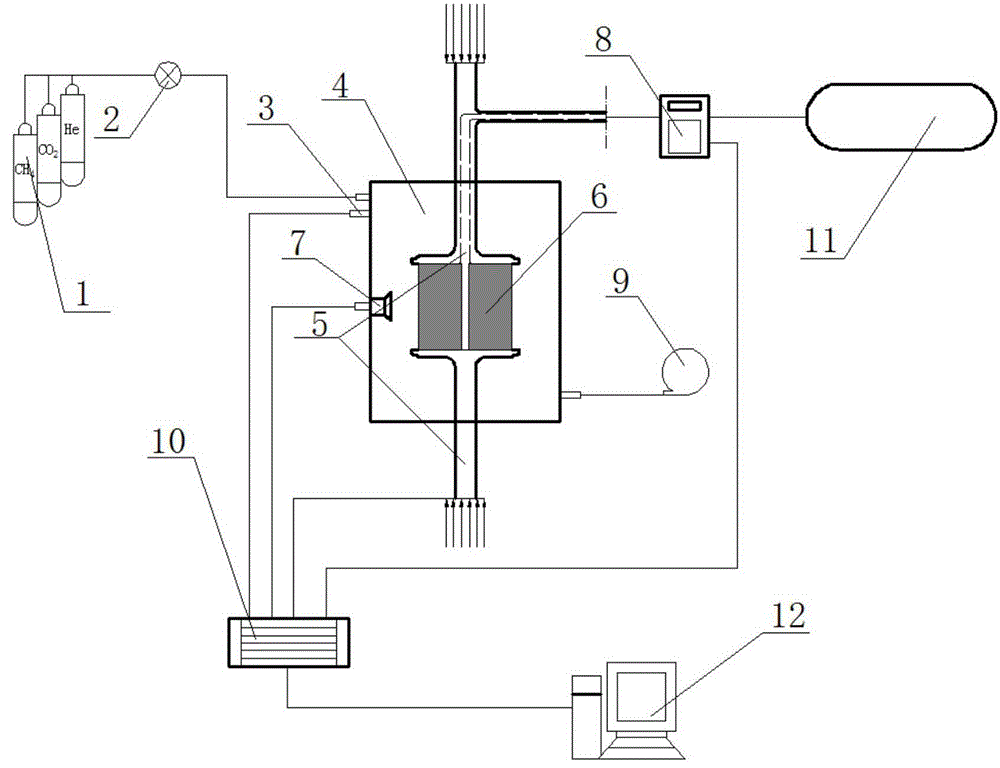

[0037] Embodiment 1: take the example (1 to 4MPa) of the permeability of methane to test coal sample, test procedure is as follows:

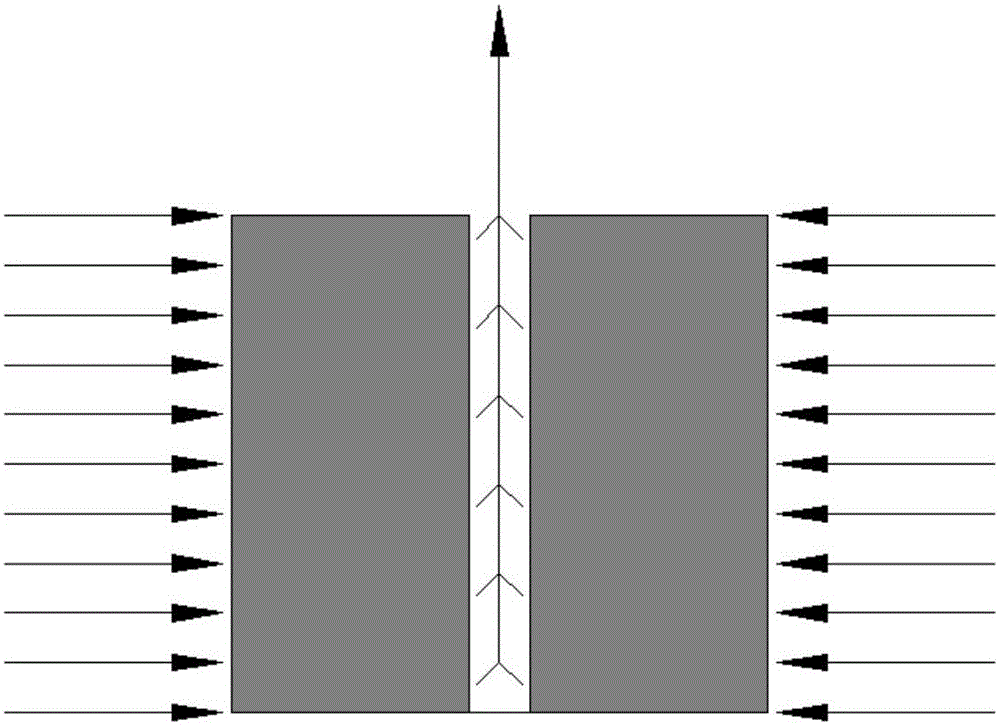

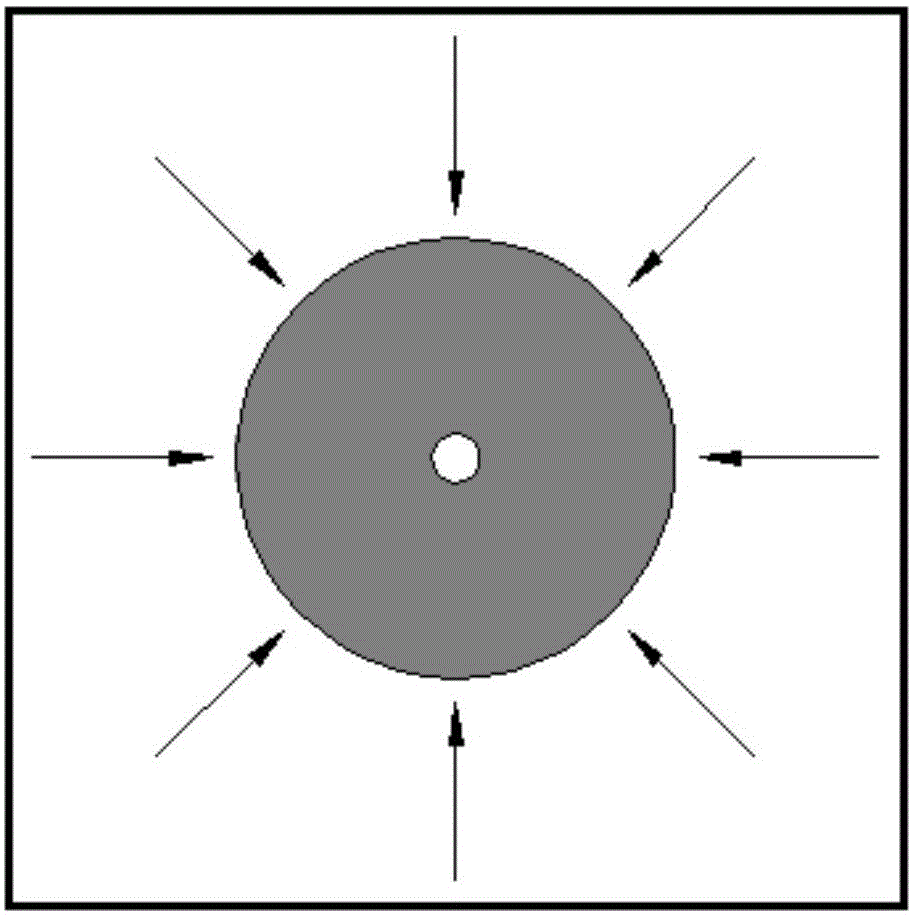

[0038] Prepare a cylindrical coal sample, punch a hole in the center, the height h of the coal sample is 50mm, and the diameter d o 54mm, the diameter of the central hole d i The upper and lower ends of the coal sample are sealed with a sealing film to ensure the radial seepage of the coal sample.

[0039] Load the coal sample on the lower tray of the axial loading mechanism in the closed pressure chamber, install the various devices of the test system, close the flow valve at the inlet end, and evacuate the closed pressure chamber.

[0040] Load the axial load to 1MPa, and then inject gas into the closed pressure chamber. After the pressure sensor shows that the gas pressure in the closed pressure chamber is stable (to ensure that the coal sample is fully adsorbed on the gas, and then the seepage of the gas inside the coal sample is stable), r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com