Frictional wear characteristic test device and method for joint curved junction surfaces

A friction and wear and characteristic testing technology, applied in the direction of testing wear resistance, etc., can solve the problems of inaccurate reliability and estimated value of friction and wear of the joint surface, low repetition rate, and high cost of the test bench, and achieves a simple and easy measurement method. line, improve utilization, uniform and convenient loading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

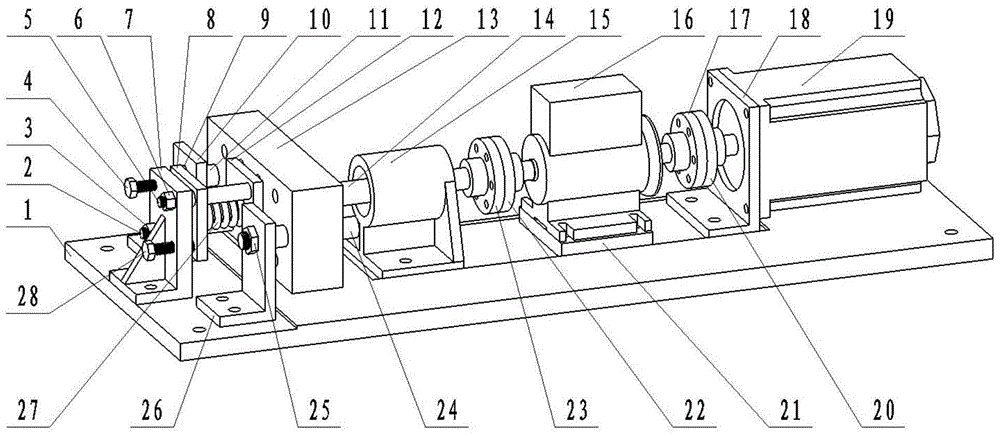

[0042] Attached below Figure 1 to Figure 7 The specific embodiment of the present invention is described further:

[0043] A test device for friction and wear characteristics of joint surfaces of joint surfaces, the test device includes a friction test device and a signal acquisition analysis and processing system; the friction test device consists of a loading system, a test joint surface system, a guide support system, a signal detection system, a support Power system composition.

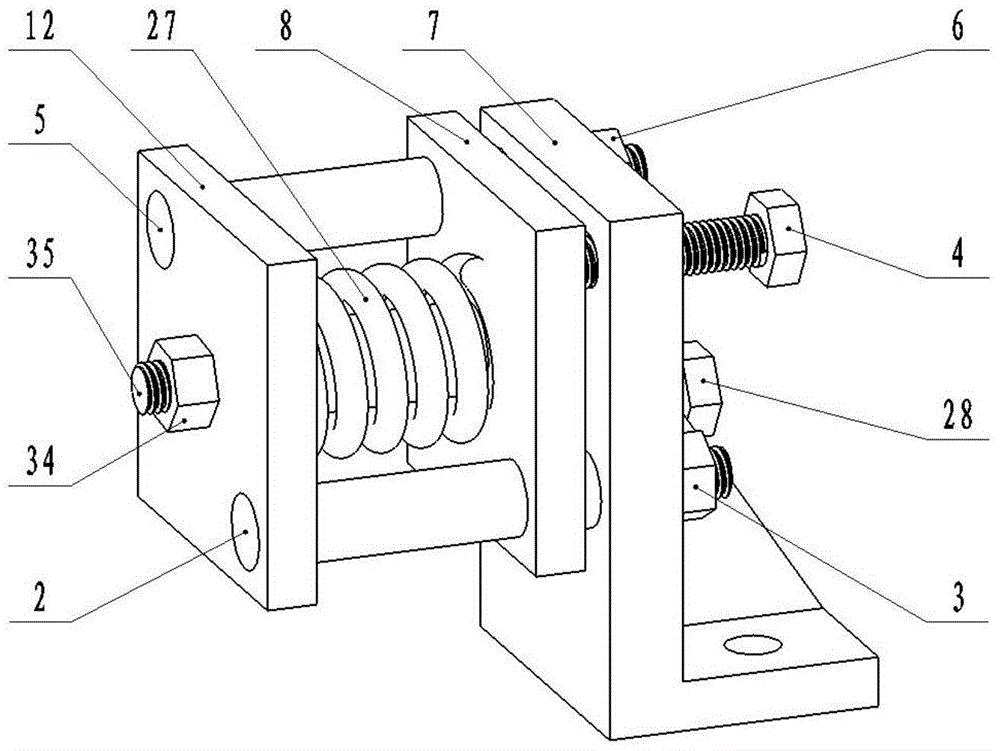

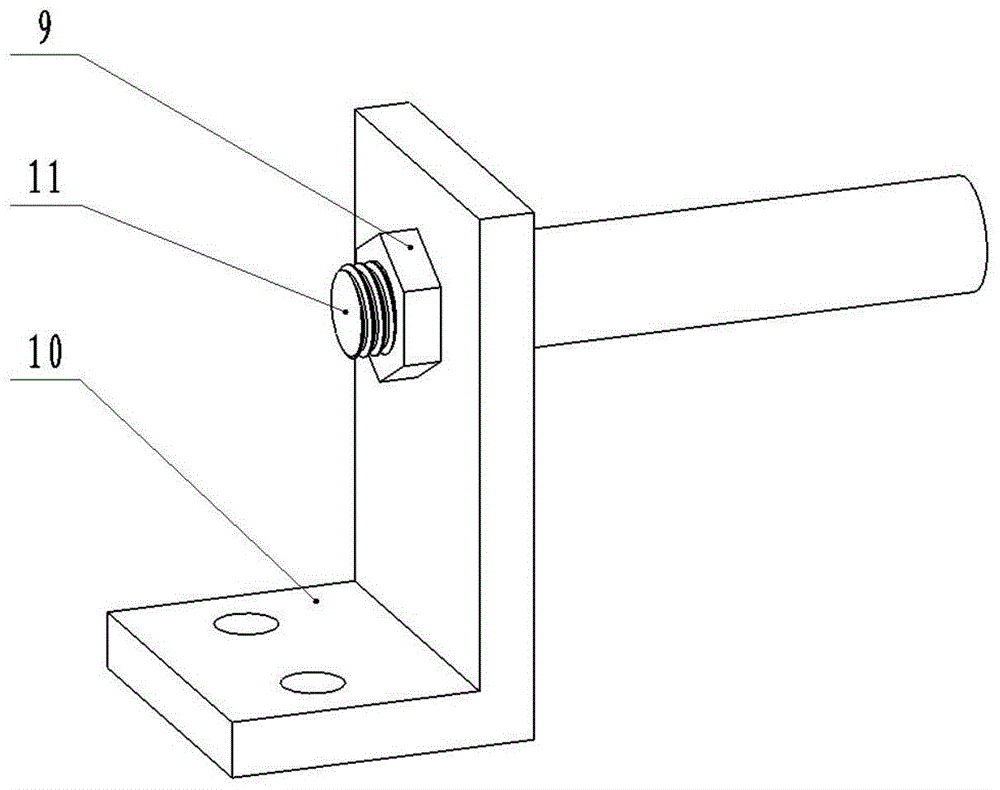

[0044] The loading system consists of loading bolt A (4), loading bolt B (28), loading nut A (3), loading nut B (6), loading rail A (2), loading rail B (5), loading support (7 ), spring seat B (8), spring seat A (12), loading spring (27), mandrel nut (34) and loading mandrel (35); loading nut A (3) and loading nut B (6) The center of the loading mandrel (35) is diagonally symmetrically arranged on the loading support (7); the other diagonal of the loading support (7) is provided with threaded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com