Hardness testing device beneficial to test precision

A technology for testing accuracy and testing instruments, which is applied in the direction of testing material hardness, instruments, and measuring devices. It can solve problems that affect test results, easily generate vibration, and cannot be placed smoothly, and achieve accurate test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

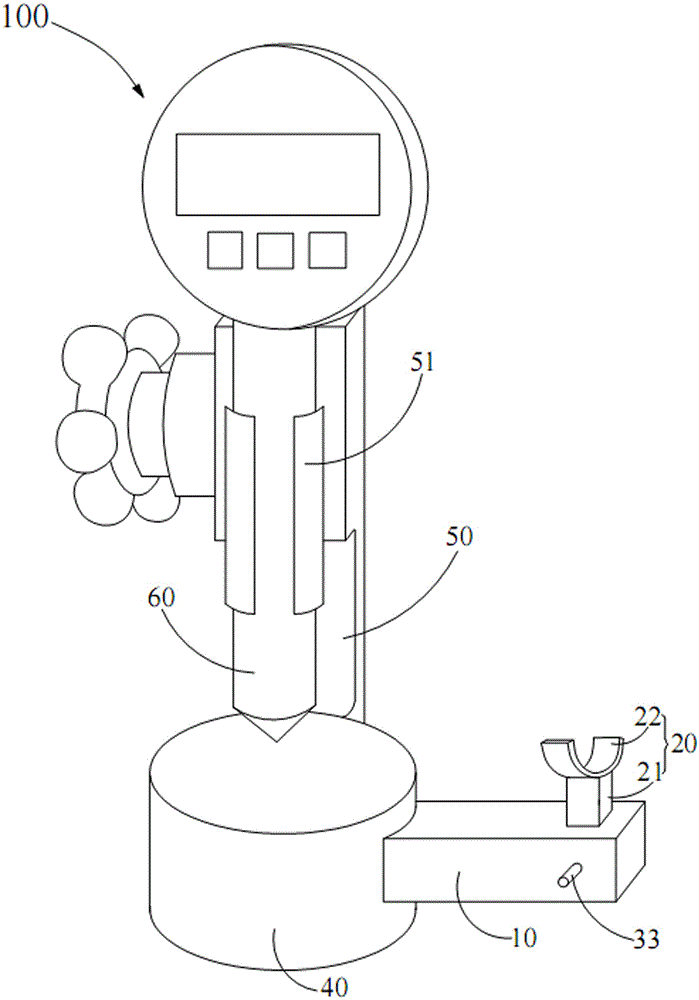

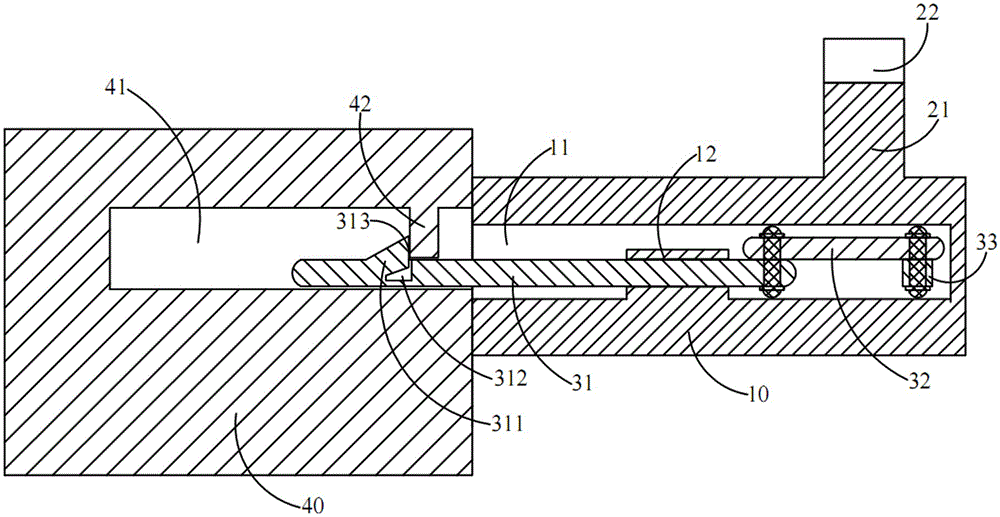

[0017] see Figure 1-3 , the hardness tester 100 shown in the preferred embodiment of the present invention includes a base 40 , a column 50 fixedly connected to the base 40 , a Shore hardness tester 60 and an external insert fixedly connected to the base 40 .

[0018] The base 40 is a cylindrical structure, a fixing hole 41 is opened on the side wall of the base 40, and a locking block 42 protrudes from the side wall of the fixing hole 41, and the locking block 42 is matched with the outer plug , so that the external insert is fixedly connected with the base 40 .

[0019] A clamp 51 for clamping the Shore hardness tester 60 protrudes from one side of the column 50 .

[0020] The external insert includes a base body 10, a fixing piece 20 and a plug-in assembly.

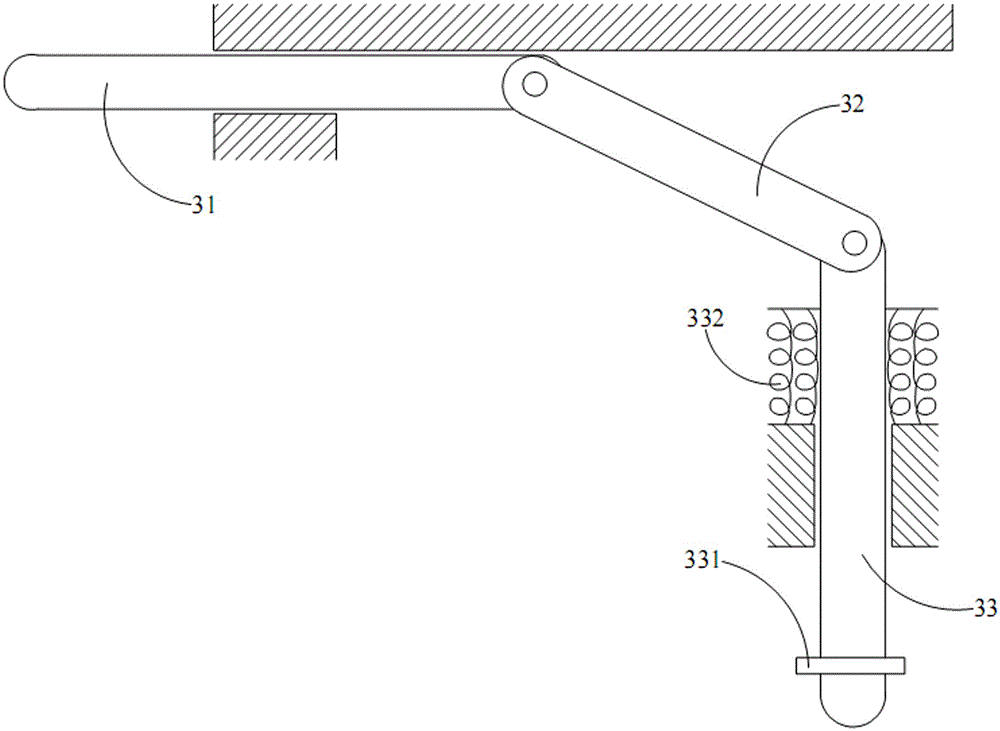

[0021] One end of the base body 10 is adjacent to the side wall of the base 40 . One end of the base body 10 adjacent to the base 40 defines a cavity 11 for matching with the plug-in assembly. A boss 12 with a thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com