Semiconductor refrigeration structure of a soda cup

A technology for semiconductors and soda cups, applied in the field of semiconductor refrigeration structures, can solve the problems of unstable material supply, influence on gas production effect, and inability to refrigerate, and achieve the effects of convenient operation, fast production speed, and prevention of dew condensation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

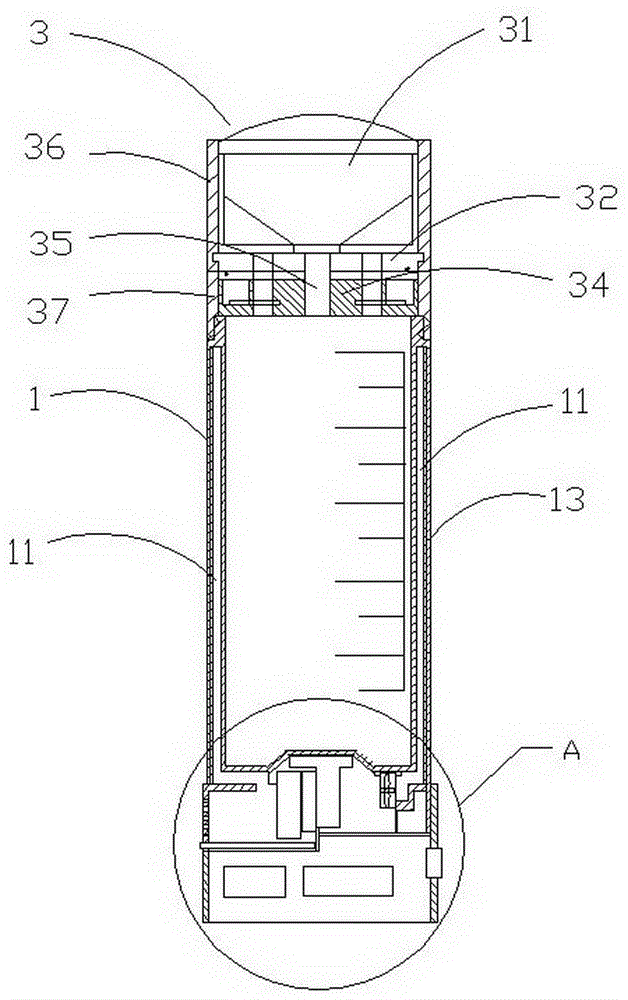

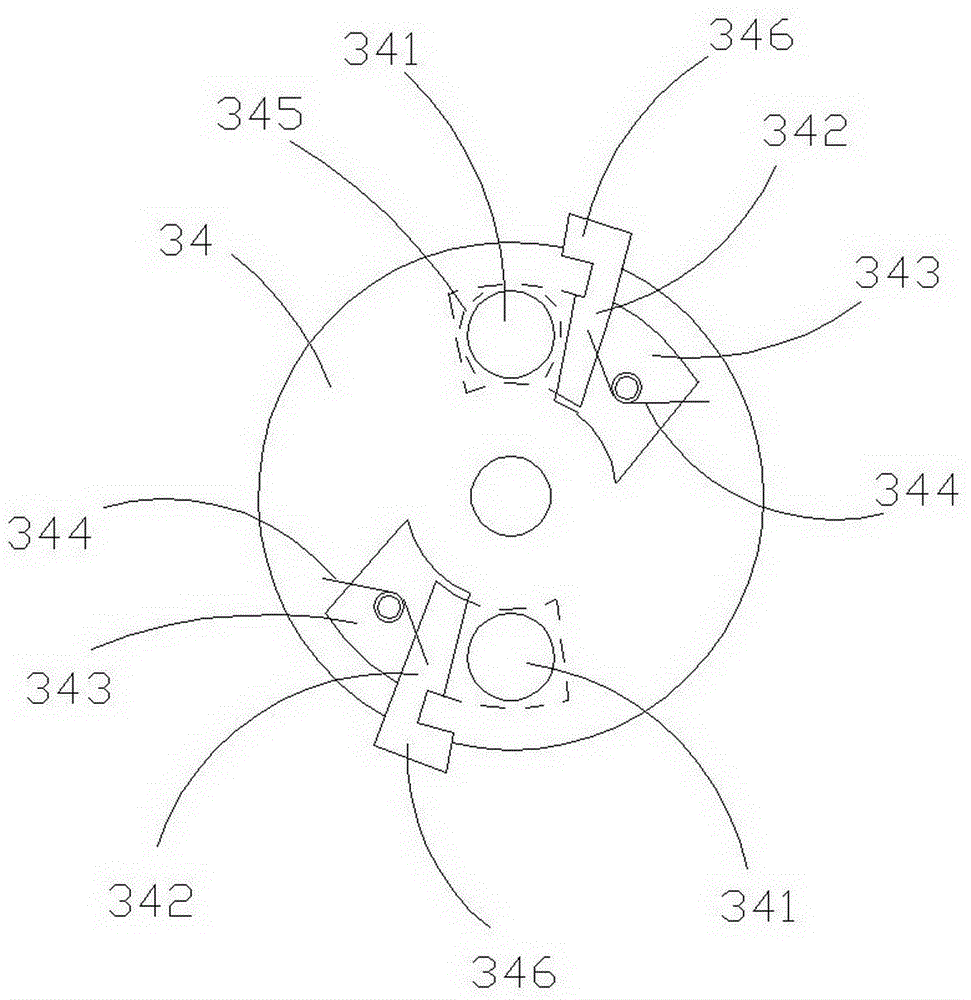

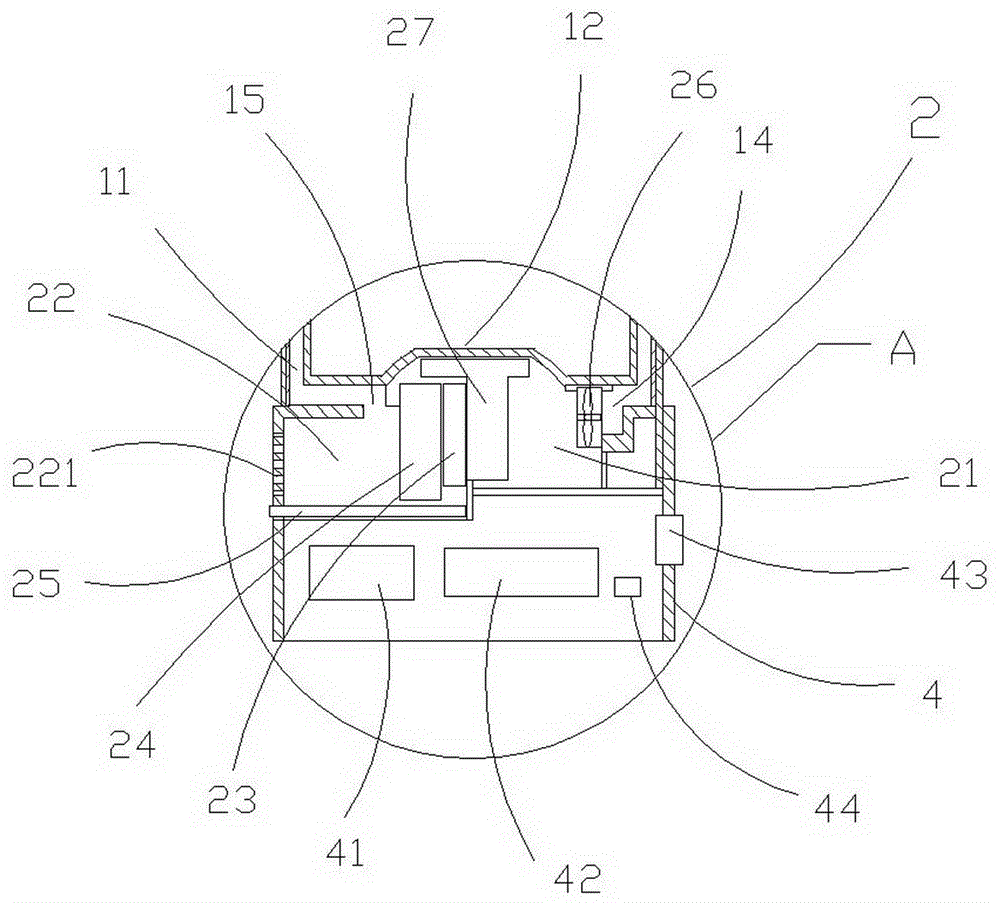

[0020] Such as figure 1 , 2 As shown, a semiconductor refrigeration structure of a soda cup includes a cup body 1, a steam-making mechanism 3 and a refrigeration device 2, the upper end of the cup body is connected to the detachable steam-making mechanism 3, and the lower end of the cup body is connected to the refrigeration device 2, The outer casing of the steam-making mechanism 3 is formed by connecting the upper part 36 and the lower part 37, the upper part 36 of the steam-making mechanism 3 can rotate, and the inner cavity of the upper part 36 is provided with a material storage chamber 31 and a metering disc 32, and the steam-making mechanism 3 The inner cavity of the lower part 37 is provided with a discharge tray 34, and the lower part 37 is threadedly connected with the cup body 1. The storage chamber 31 and the metering disc 32 in the upper part 36 of the steam making mechanism 3 are connected with the discharge disc 34 in the lower part 37 by the mandrel 35 in sequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com