A method for fixing the peripheral structure of curtain wall glass

A fixing method and glass technology, which is applied in the installation of window glass, walls, building components, etc., can solve the problems of glass breakage, glass breakage, and reduce glass falling, so as to improve the aesthetics, enhance the connection strength, and avoid easy breakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

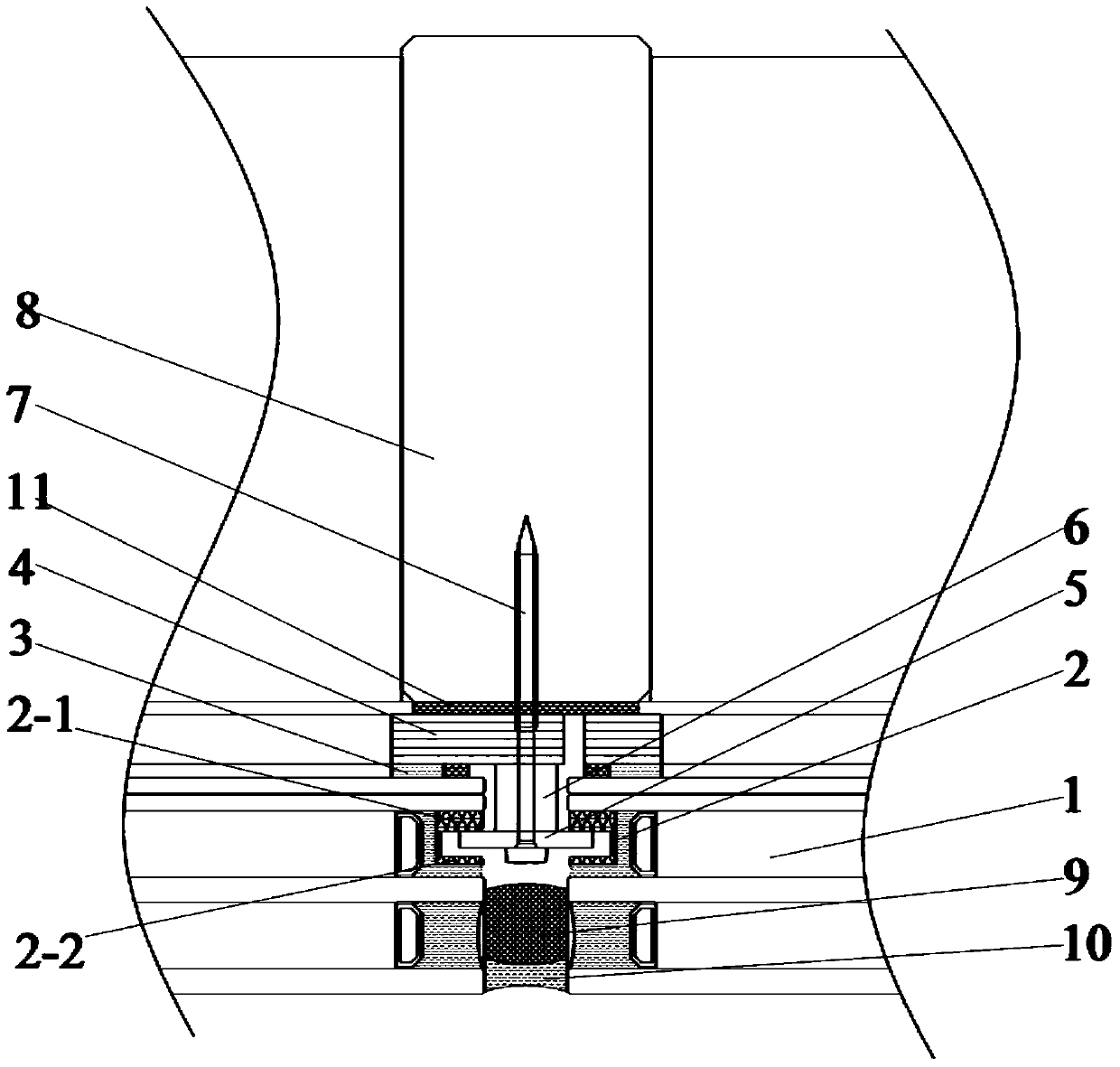

[0026] A method for fixing the peripheral structure of curtain wall glass provided by the present invention comprises the following steps:

[0027] Step 1: Set a U-shaped groove 2 in the interlayer between the two layers of glass of the insulating glass 1, and the opening of the U-shaped groove 2 faces the periphery of the glass; paste the corrugated plate 4 on the inner periphery of the insulating glass 1 through the structural glue 3;

[0028] Step 2: Place glass inner compacts 5 in the U-shaped grooves 2 where the openings of two adjacent insulating glasses 1 are opposite, and place glass compact holders 6 inside the glass inner compacts 5, the through holes of the glass inner compacts 5 and the glass The through hole of the briquetting holder 6 is connected;

[0029] Step 3: Engage the corrugated plates 4 of two adjacent insulating glasses 1, install the sealing tape 11 between the corrugated plates 4 and the frame 8, pass through the glass inner briquetting block 5, the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com