A curtain wall glass peripheral structure

A glass and peripheral technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of glass breakage, glass breakage, reduce glass fall, etc., to improve the degree of heat preservation, avoid brittleness, and ensure the effect of sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

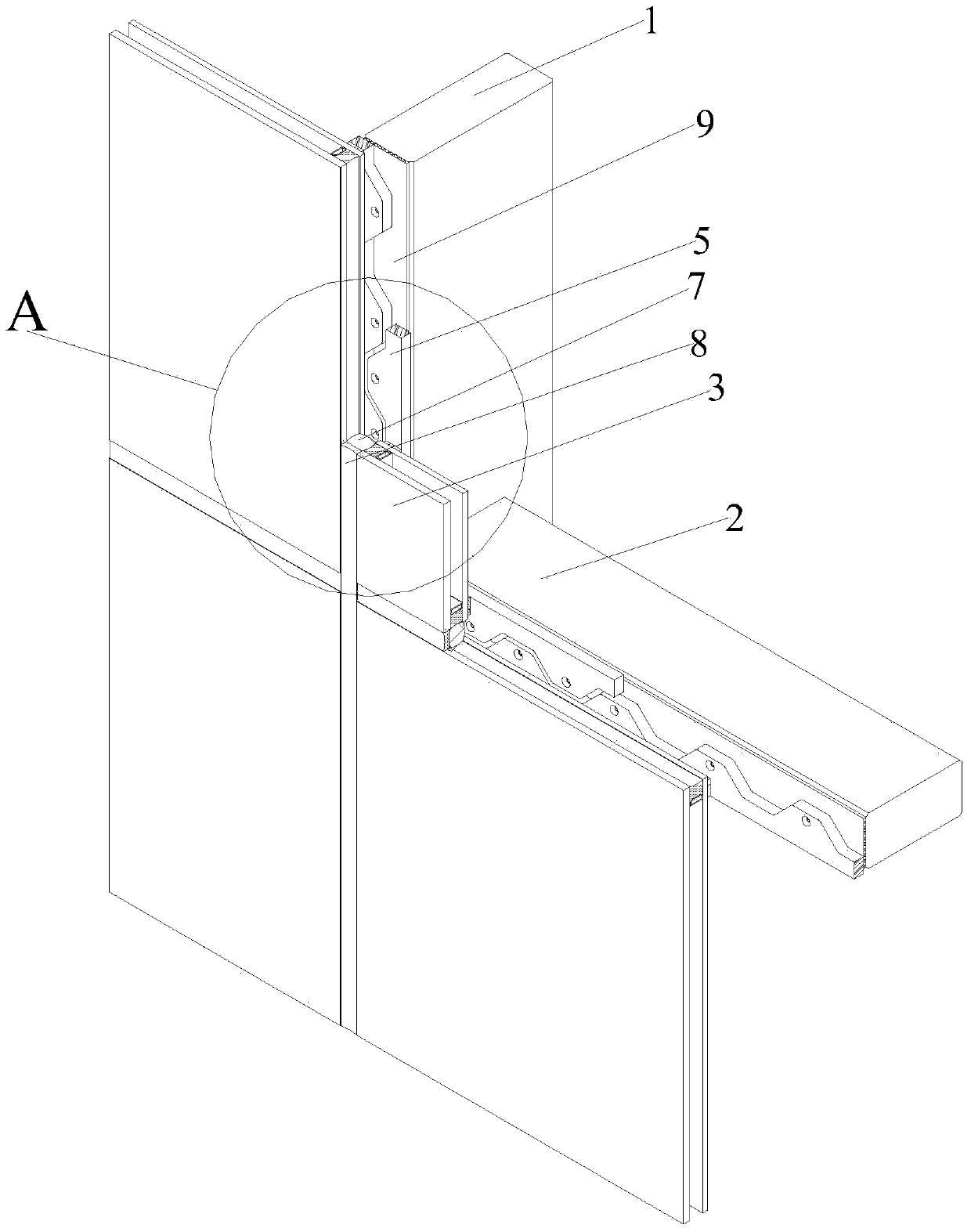

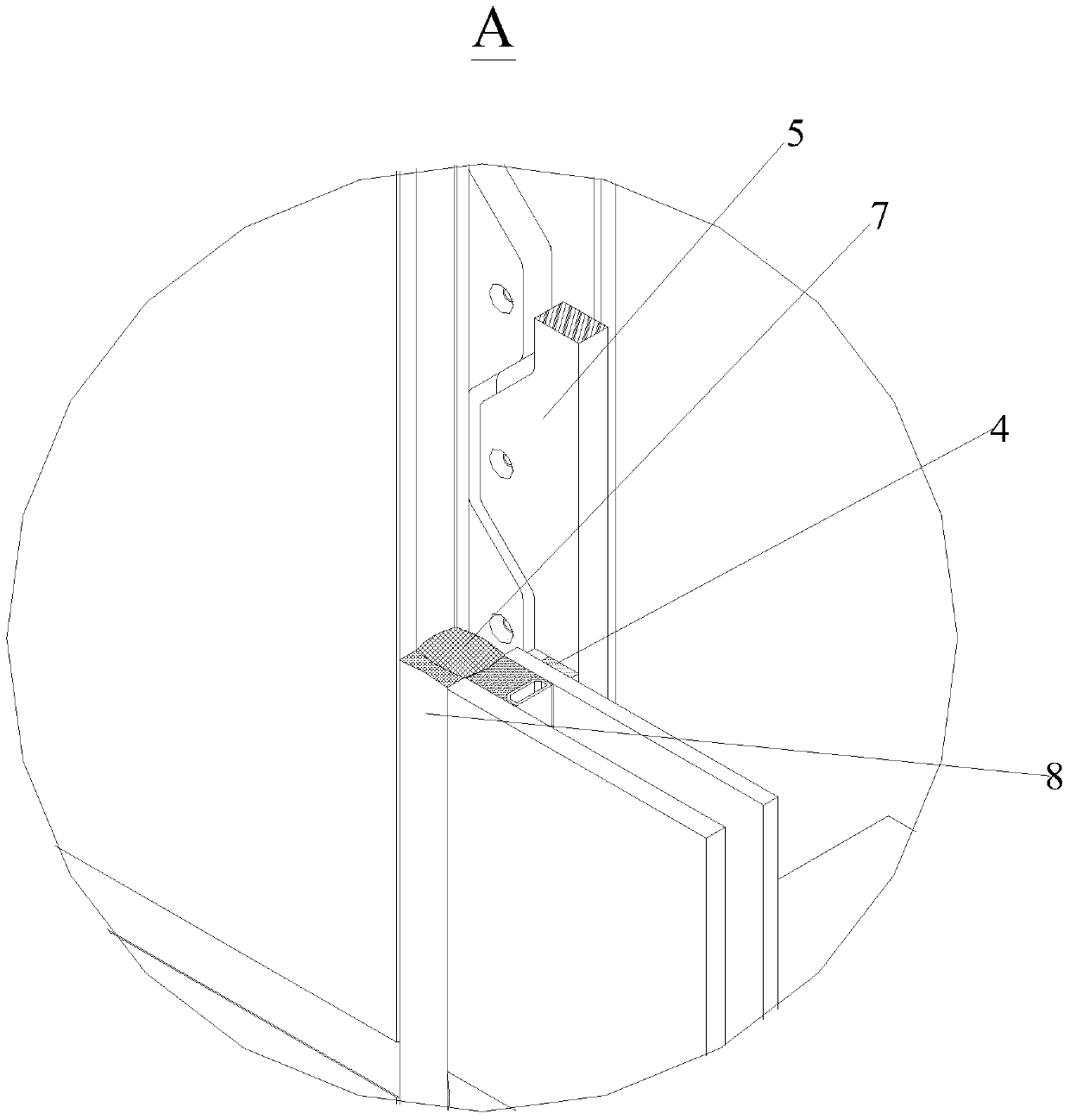

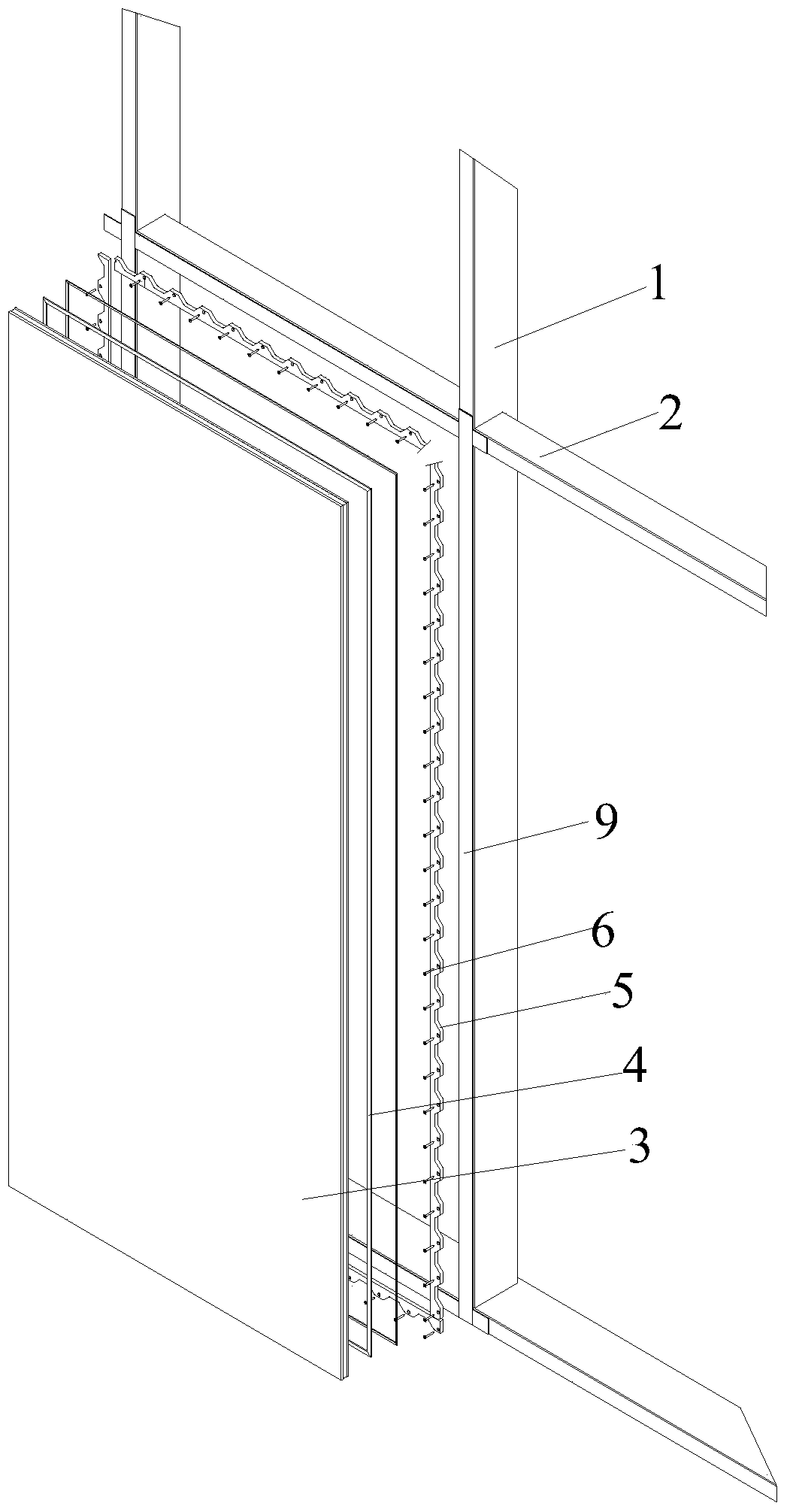

[0023] Such as figure 1 , figure 2 , image 3 As shown, a curtain wall glass peripheral structure provided by the present invention includes a column 1 and a beam 2, and a glass 3 arranged outside the support frame formed by the column 1 and the beam 2. There are through holes in the crests of the plates 5 and corrugated plates 5, and the glass 3 is fixed on the outside of the support frame through the through holes through the screws 6, and the corrugated plates 5 of two adjacent glasses 3 are engaged with each other.

[0024] In the above embodiment, the corrugated plate 5 includes a bonding portion and an occlusal portion. The bonding portion and the occlusal portion are integrally structured. Located outside the edge of the glass. The rough bonding portion can provide bonding strength with the glass 3 . The corrugated plate 5 is a birch plywood, which has the effect of heat preservation and heat insulation. The through holes on the two interlocking corrugated plates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com