Ultra-low carbon bainite thin gauge steel plate rolled through heavy and medium plate mill and production method of ultra-low carbon bainite thin gauge steel plate

A production method and ultra-low carbon technology, applied in the direction of temperature control, etc., can solve the problems of increasing smelting cost, production limitation, affecting the mechanical properties and shape of the steel plate, achieving excellent welding performance and cold working formability, and ensuring temperature uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

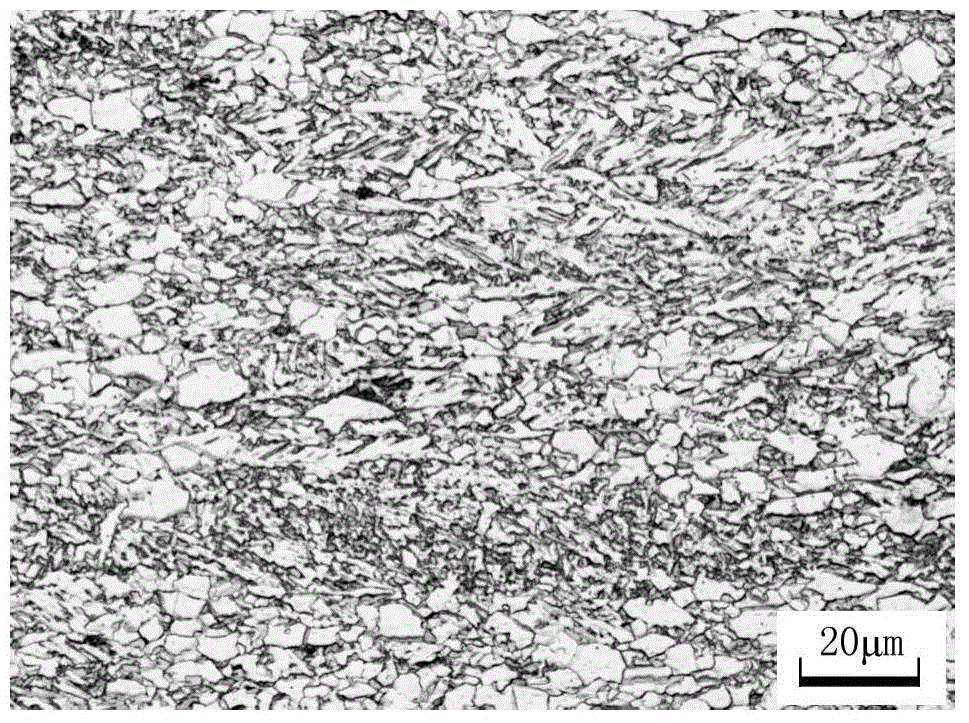

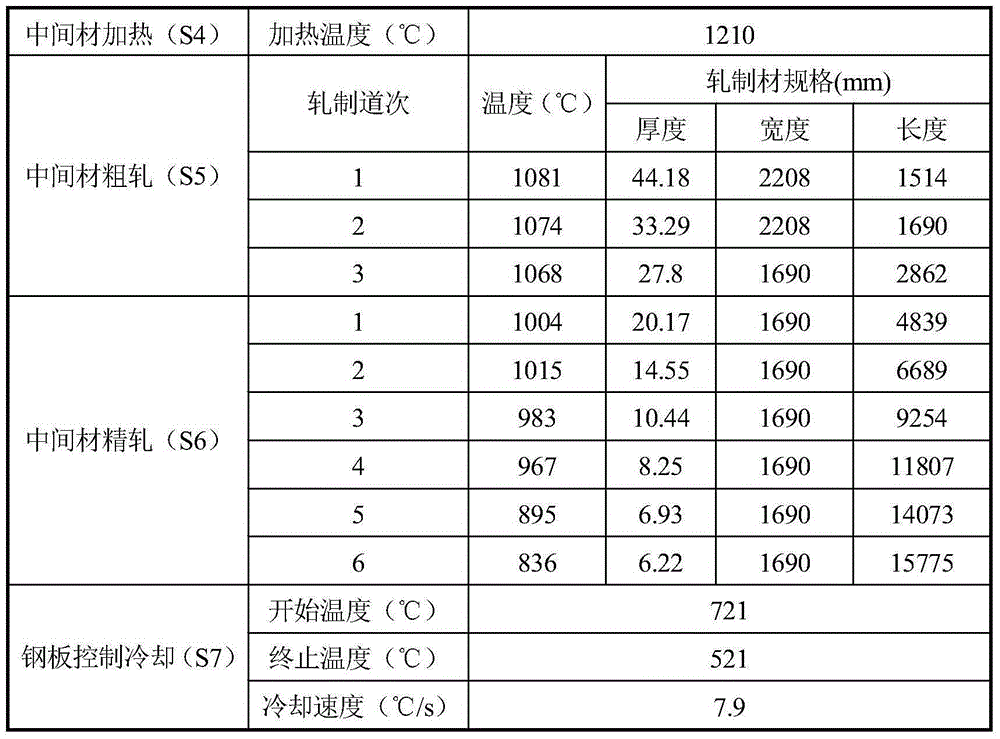

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with specific examples.

[0036] The mass percentage distribution of chemical elements in the steel sheets of Examples 1-4 of the present invention is shown in Table 1, and the balance is Fe and unavoidable impurities.

[0037] The chemical composition mass percentage (Wt%) of the embodiment of the present invention 1-4 of table 1

[0038] Example

C

Si

mn

P

S

Cu

B

Ni

Mo

Cr

Nb

V

Ti

Al

1

0.020

0.40

1.70

0.018

0.005

0.35

0.00010

0.15

0.20

0.45

0.015

0.060

0.019

0.015

2

0.055

0.20

1.40

0.016

0.003

0.20

0.00015

0.40

0.20

0.25

0.024

0.055

0.018

0.031

3

0.055

0.25

1.35

0.013

0.002

0.35

0.00020

0.42

0.18

0.20

0.028

0.060

0.010

0.045

4

0.080

0.10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| impact absorption energy | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com