Preparation method and application of compound plant essential oil and microcapsule product thereof

A technology of compound plant essential oil and microcapsules is applied in the field of preparation of compound plant essential oil and microcapsule products thereof, which can solve the problems of short retention time of essence and uneven release of essence, avoid the deterioration of essence, improve the quality and production of cigarette smoking food. The effect of simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

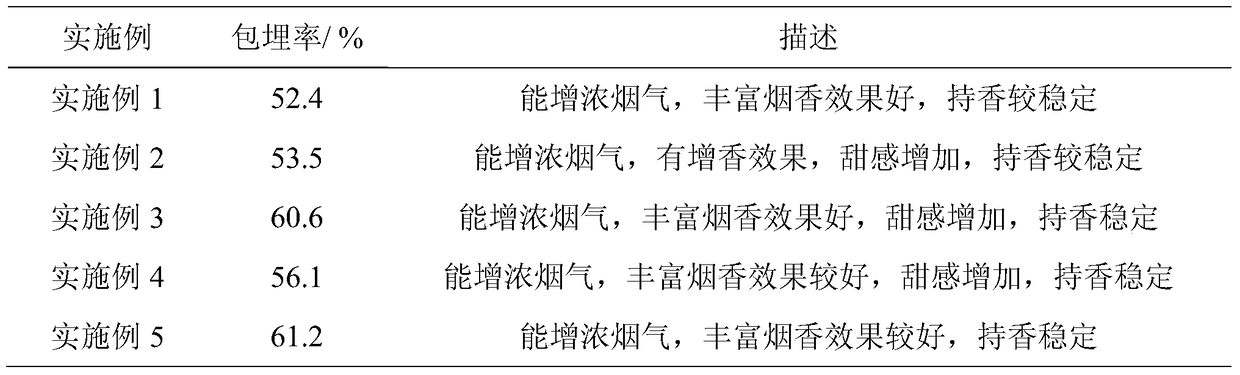

Examples

Embodiment 1

[0031] Preparation of the compound plant essential oil: mix green calyx plum, tangerine peel, and light bamboo leaves in a weight ratio of 1:1:1, crush them, soak in distilled water for 12 hours, put them in a volatile oil extractor, and extract the volatile oil from them by steam distillation. .

[0032] Preparation of microcapsule products of compound plant essential oils: use β-cyclodextrin as wall material, and prepare β-cyclodextrin aqueous solution according to β-cyclodextrin:water=1:6 (mass ratio). The compound plant essential oil is used as the core material, and the compound plant essential oil is added to the β-cyclodextrin aqueous solution according to the core-to-wall ratio of 1:8 (mass ratio). Control the temperature at 50°C, stir for 2 hours and take it out. After the solution is cooled to room temperature, put it in a refrigerator at 4°C for 24 hours, filter it with suction, and dry it at low temperature to constant mass to obtain the microcapsule product.

[0...

Embodiment 2

[0035] Preparation of compound plant essential oil: mix green calyx plum, tangerine peel, and light bamboo leaves in a weight ratio of 1:2:1, crush them, soak in distilled water for 12 hours, put them in a volatile oil extractor, and extract the volatile oil from them by steam distillation. .

[0036] Preparation of microcapsule products of compound plant essential oils: use β-cyclodextrin as wall material, and prepare β-cyclodextrin aqueous solution according to β-cyclodextrin:water=1:6 (mass ratio). The compound plant essential oil is used as the core material, and the compound plant essential oil is added to the β-cyclodextrin aqueous solution according to the core-to-wall ratio of 1:8 (mass ratio). Control the temperature at 50°C, stir for 2 hours and take it out. After the solution is cooled to room temperature, put it in a refrigerator at 4°C for 24 hours, filter it with suction, and dry it at low temperature to constant mass to obtain the microcapsule product.

[0037]...

Embodiment 3

[0039] Preparation of compound plant essential oil: mix green calyx plum, tangerine peel, and light bamboo leaves in a weight ratio of 1:2:1, crush them, soak in distilled water for 12 hours, put them in a volatile oil extractor, and extract the volatile oil from them by steam distillation. .

[0040] Preparation of microcapsule products of compound plant essential oils: use β-cyclodextrin as wall material, and prepare β-cyclodextrin aqueous solution according to β-cyclodextrin:water=1:6 (mass ratio). The compound plant essential oil is used as the core material, and the compound plant essential oil is added to the β-cyclodextrin aqueous solution according to the core-to-wall ratio of 1:10 (mass ratio). Control the temperature at 50°C, stir for 1 hour and take it out. After the solution is cooled to room temperature, put it in a refrigerator at 4°C for 24 hours, filter it with suction, and dry it at low temperature to constant mass to obtain the microcapsule product.

[0041]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com