A vacuum degassing packaging system for inorganic flame retardant powder

An inorganic flame retardant and packaging system technology, which is applied in the directions of packaging, transportation and packaging, and the type of packaging items, can solve the problems that inorganic flame retardant powder cannot be recycled, increase production costs, affect packaging efficiency, etc., and achieve savings. The effect of workshop equipment cost, reducing labor intensity and saving personnel maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

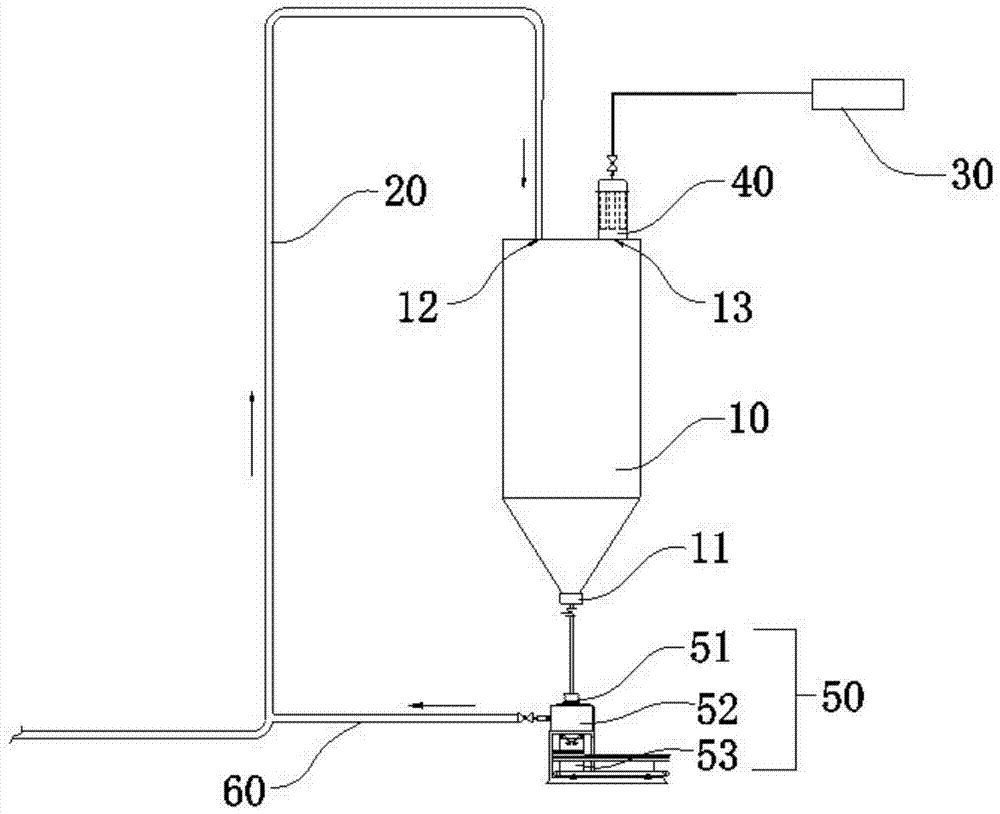

[0027] This embodiment provides a vacuum degassing packaging system for inorganic flame retardant powder. Taking its application in the packaging of magnesium hydroxide or aluminum hydroxide or other inorganic flame retardants as an example, its structure is introduced below, as figure 1 As shown, it includes at least:

[0028] The silo 10 for accommodating the inorganic flame retardant powder includes an outlet 11 at the bottom, an inlet 12 and a decompression port 13 corresponding to the outlet. The feeding pipeline 20 is connected with the inlet 12 and is used for bringing the inorganic flame retardant powder into the silo 10 through airflow. Generally, the inner diameter of the feeding pipeline is 70-100m. Preferably, in order to use the magnesium hydroxide flame retardant powder to settle and concentrate in the outlet 11 by its own gravity, the outlet 11 is set in a funnel shape. Preferably, in order to improve the discharge effect, a switch or valve, such as a rotary f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com