Production method of full continuous concrete and its system

A production system and concrete technology, applied in chemical instruments and methods, clay preparation equipment, mixing operation control, etc., can solve discontinuous problems, achieve continuous mixing and transportation, low cost, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

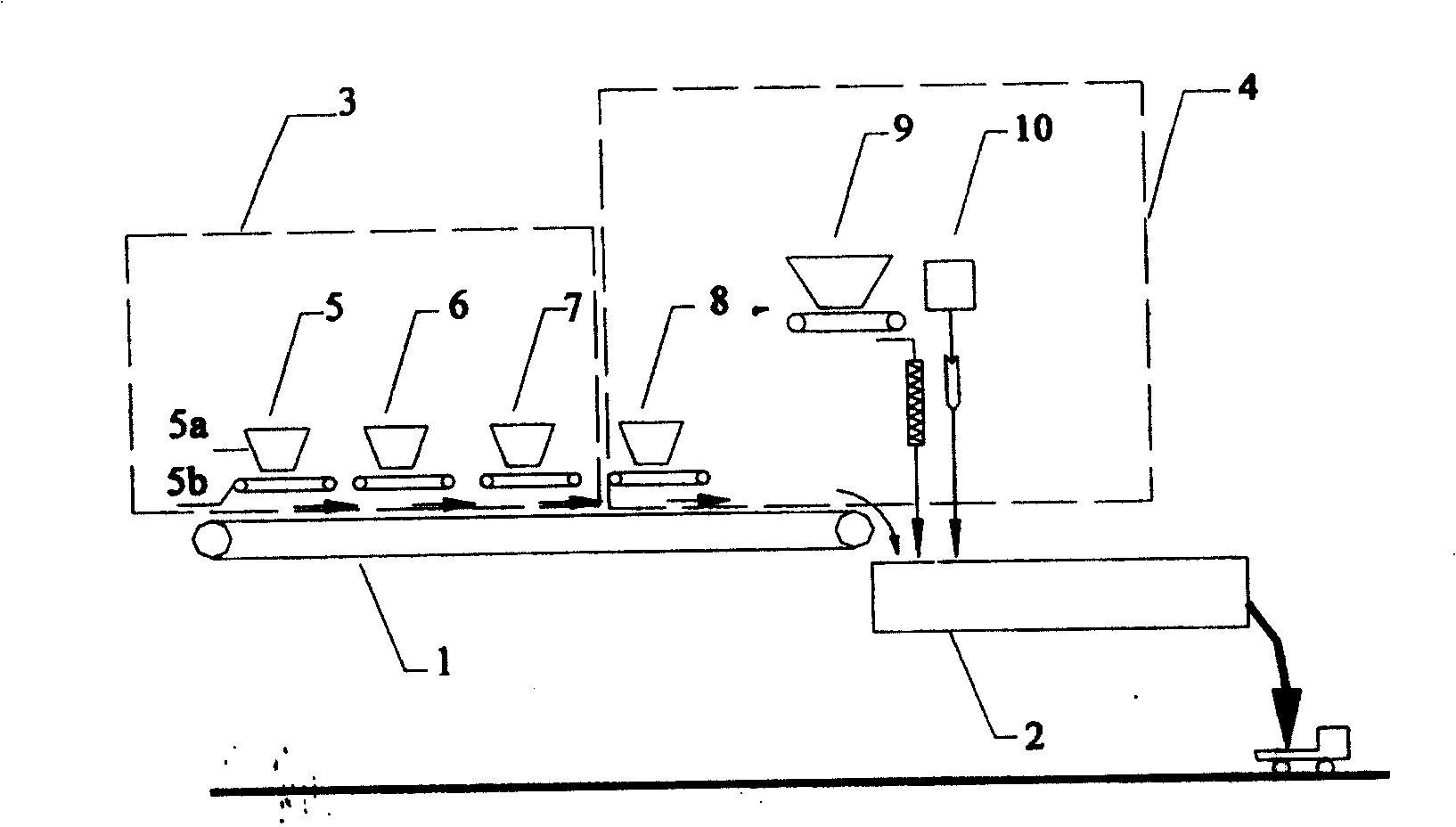

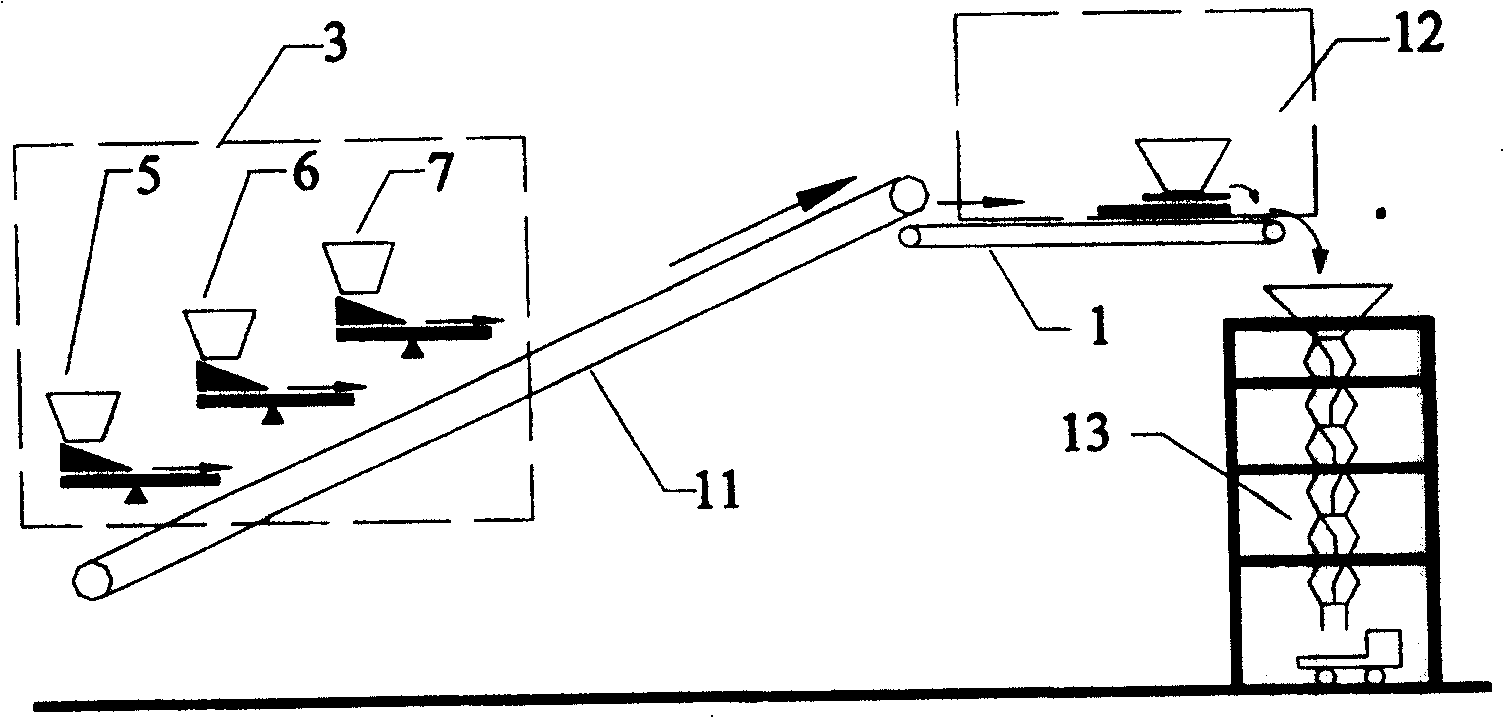

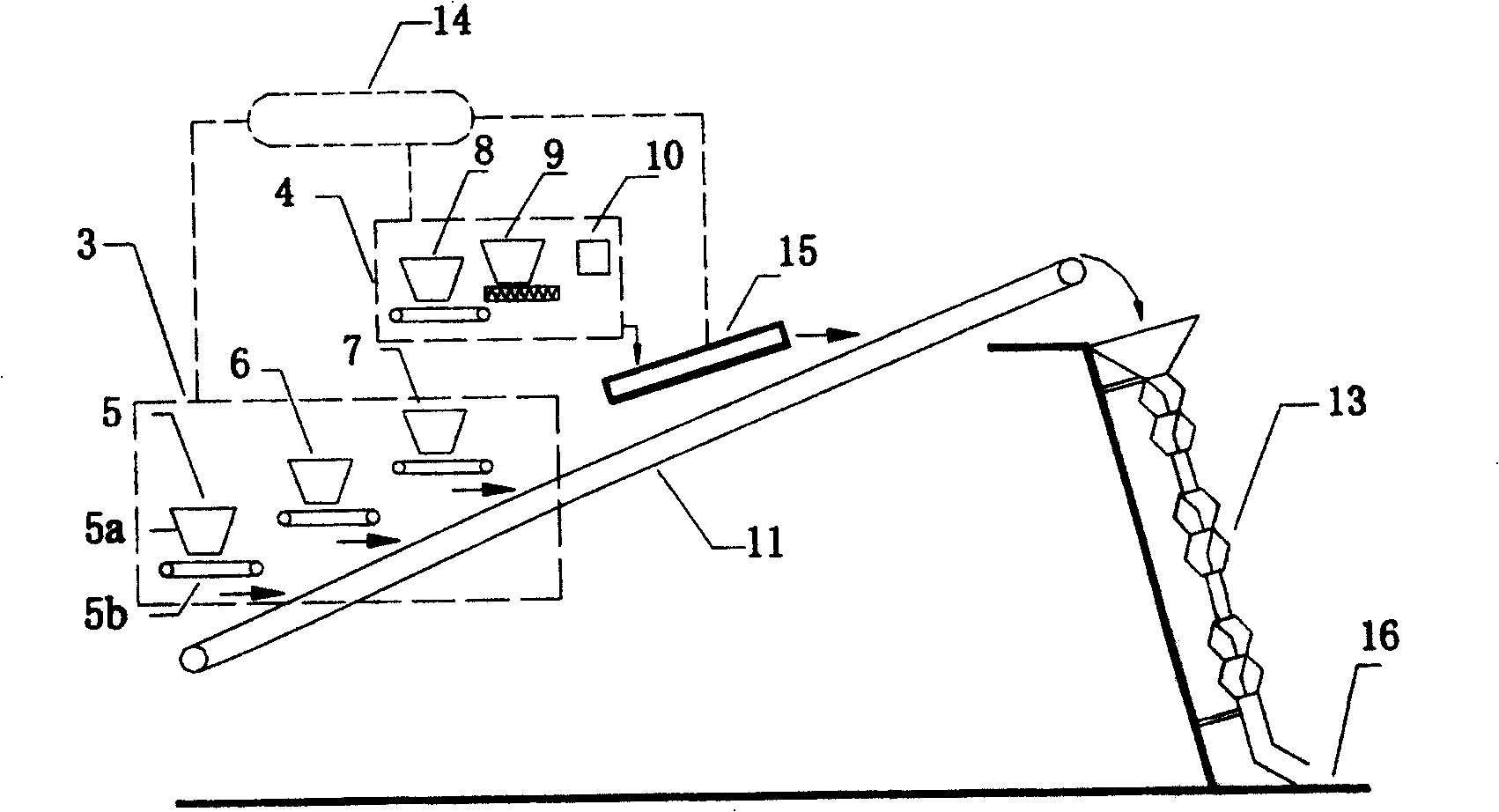

[0021] One of the cores of the present invention is that materials are input at the same time, and the production of mortar is continuous. Through the continuous stirring and conveying of the continuous mortar mixer, the coarse aggregate and mortar can be continuously conveyed to the static mixing device for continuous mixing of concrete at the same time; The second core of the invention is to use MY-BOX as a vertical conveying system. In order to realize the continuous production of the whole process of material input, weighing, conveying, mixing and transportation, it is a fully continuous concrete production system.

[0022] Introduce the fully continuous concrete production system of the present invention below in conjunction with accompanying drawing.

[0023] image 3Shown is a schematic diagram of the fully continuous concrete production system of the present invention. The operation control system 14 controls the coarse aggregate continuous feeding system 3 , the mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com