Pole-climbing robot with stabilizing device

A stabilization device and robot technology, applied in the field of pole-climbing robots, can solve problems such as poor stability, and achieve the effects of low cost, high motion stability, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

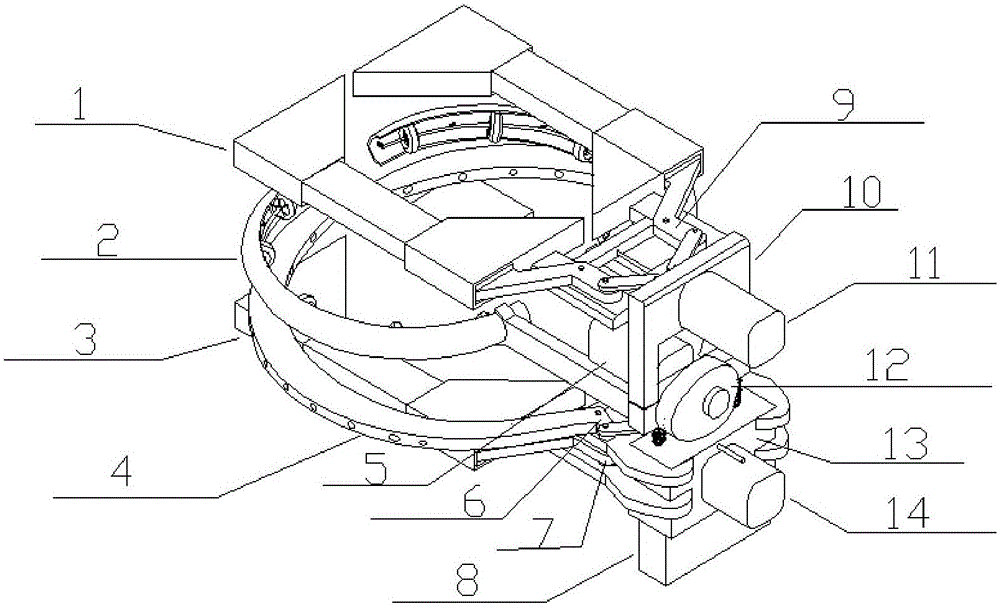

[0015] Specific implementation mode one: combine Figure 1 to Figure 6 Describe this embodiment, this embodiment includes a first manipulator 1, a stabilizing device 2, a second manipulator 3, a working manipulator 4, a second motor 11, a first crank linkage mechanism 6, a second crank linkage mechanism 7, and a storage battery 8 , the third crank linkage mechanism 9, the third motor 14 and the linear telescopic mechanism, the linear telescopic mechanism drives the first manipulator 1 and the second manipulator 3 to move up and down,

[0016] The storage battery 8 is installed in the lower end of the linear telescopic mechanism and provides power for the linear telescopic mechanism, the second manipulator 3 is installed in the bottom of the linear telescopic mechanism by the second crank linkage 7, and the third motor 14 is installed in the bottom of the linear telescopic mechanism and is connected with the linear telescopic mechanism. The second crank linkage mechanism 7, and...

specific Embodiment approach 2

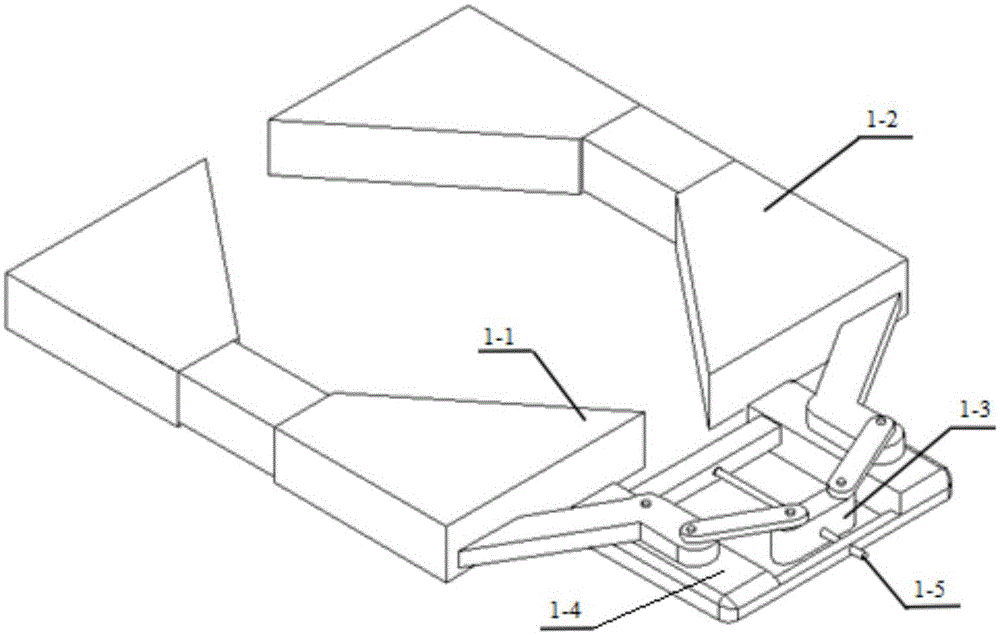

[0019] Specific implementation mode two: combination figure 1 and image 3 Describe this embodiment, the structure of the first manipulator 1 and the second manipulator 3 of this embodiment is the same, the first manipulator 1 comprises left hand claw 1-1, right hand claw 1-2, walking slider 1-3, walking link 1- 4 and walking screw 1-5,

[0020] Left-hand claw 1-1 and right-hand claw 1-2 are arranged oppositely, and the inner sides of left-hand claw 1-1 and right-hand claw 1-2 are provided with inner pits, and the same side of left-hand claw 1-1 and right-hand claw 1-2 The outer wall is connected with a walking link 1-4, the walking slider 1-3 is installed in the walking link 1-4, and the walking screw 1-5 passes through the walking slider 1-3 and is installed in the walking link 1-4 On, one end of the third crank-link mechanism 9 is connected with the same side outer wall of the left claw 1-1 and the right claw 1-2, and the other end of the third crank-link mechanism 9 is c...

specific Embodiment approach 3

[0021] Specific implementation mode three: combination figure 1 and Figure 4 Describe this embodiment, the stabilizing device 2 of this embodiment comprises two 1 / 2 stabilizing components, two 1 / 2 stabilizing components are oppositely connected to form the stabilizing device 2, and each 1 / 2 stabilizing component includes a concave One-half shell 2-1 of groove, rolling shaft 2-2, connecting rod 2-5, multiple wheels 2-3 and multiple springs 2-4, rolling shaft 2-2 is installed by multiple springs 2-4 In the half shell 2-1 with groove, a plurality of wheels 2-3 are set on the rolling shaft 2-2, and one end of connecting rod 2-5 is installed on the half shell with groove 2-1, the other end of the connecting rod 2-5 is connected with the linear expansion mechanism. Other connection methods are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com