Full-automatic stainless steel ring welding machine

A stainless steel ring, fully automatic technology, applied in welding equipment, laser welding equipment, welding/welding/cutting items, etc., can solve the problems of inability to meet the production requirements of steel strip welding, low machining accuracy of welding machines, and high maintenance costs , to achieve the effect of low maintenance cost, high machining accuracy and reduced maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

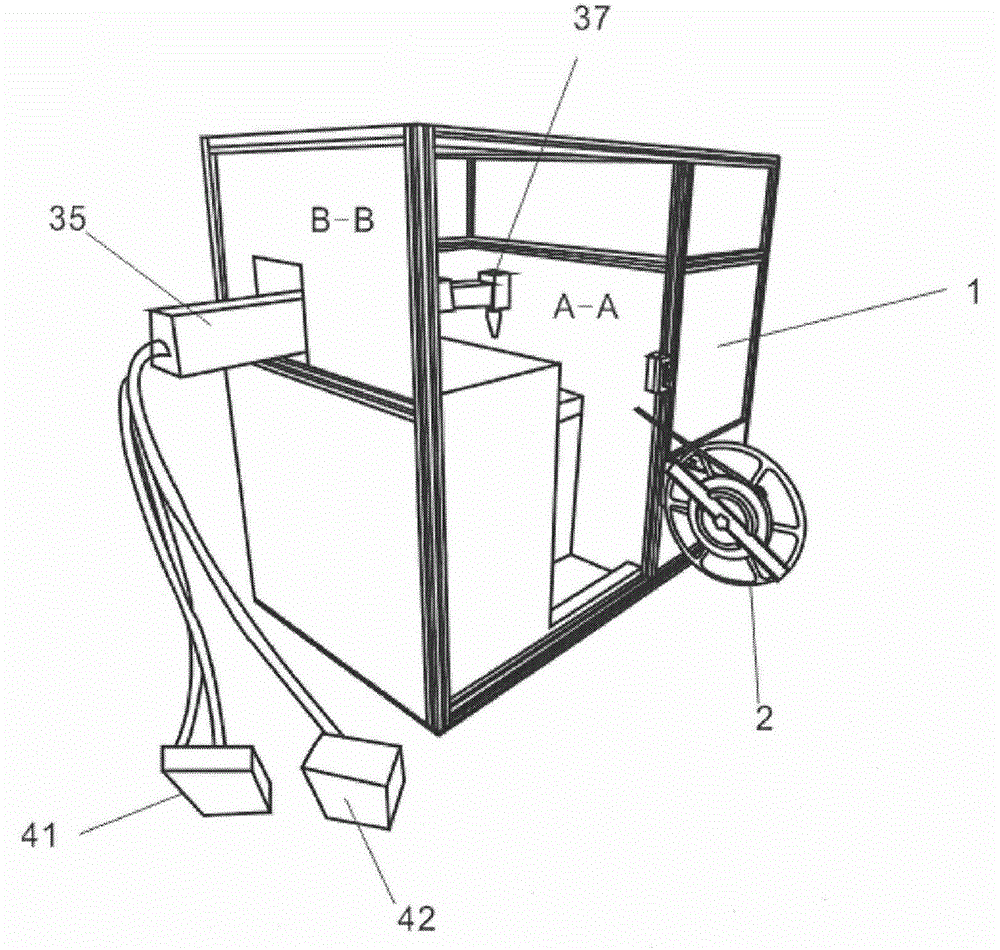

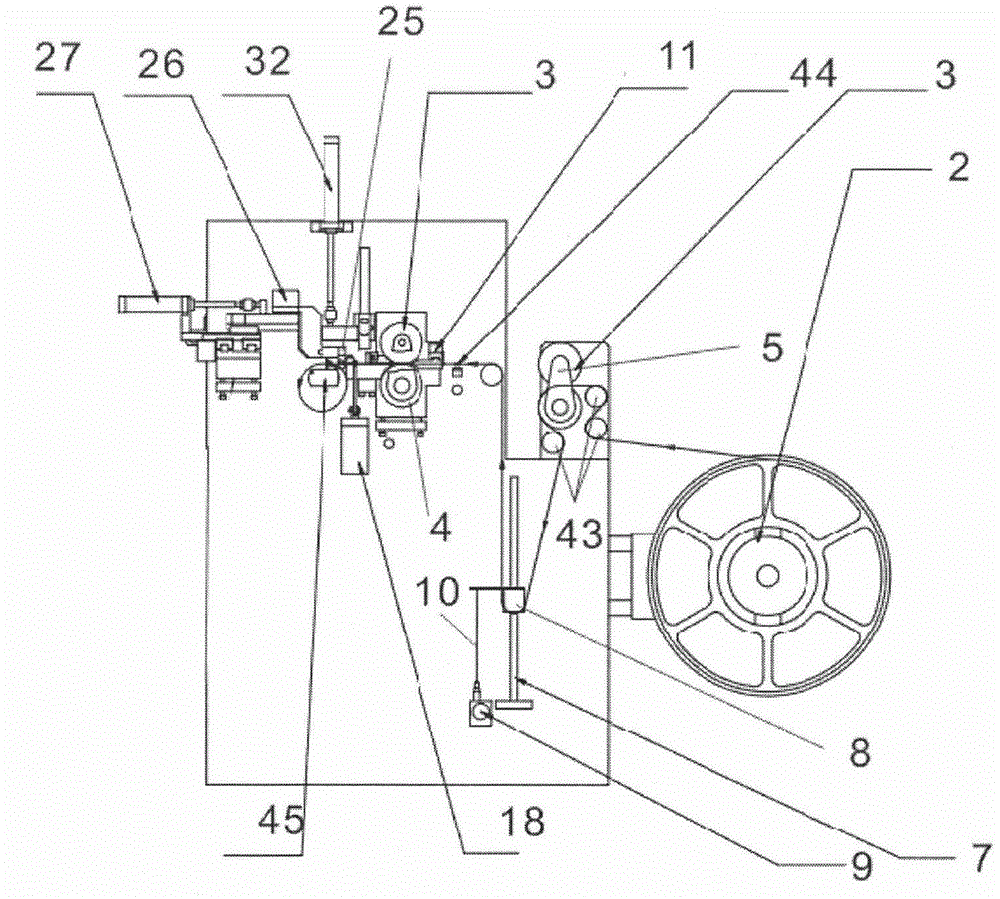

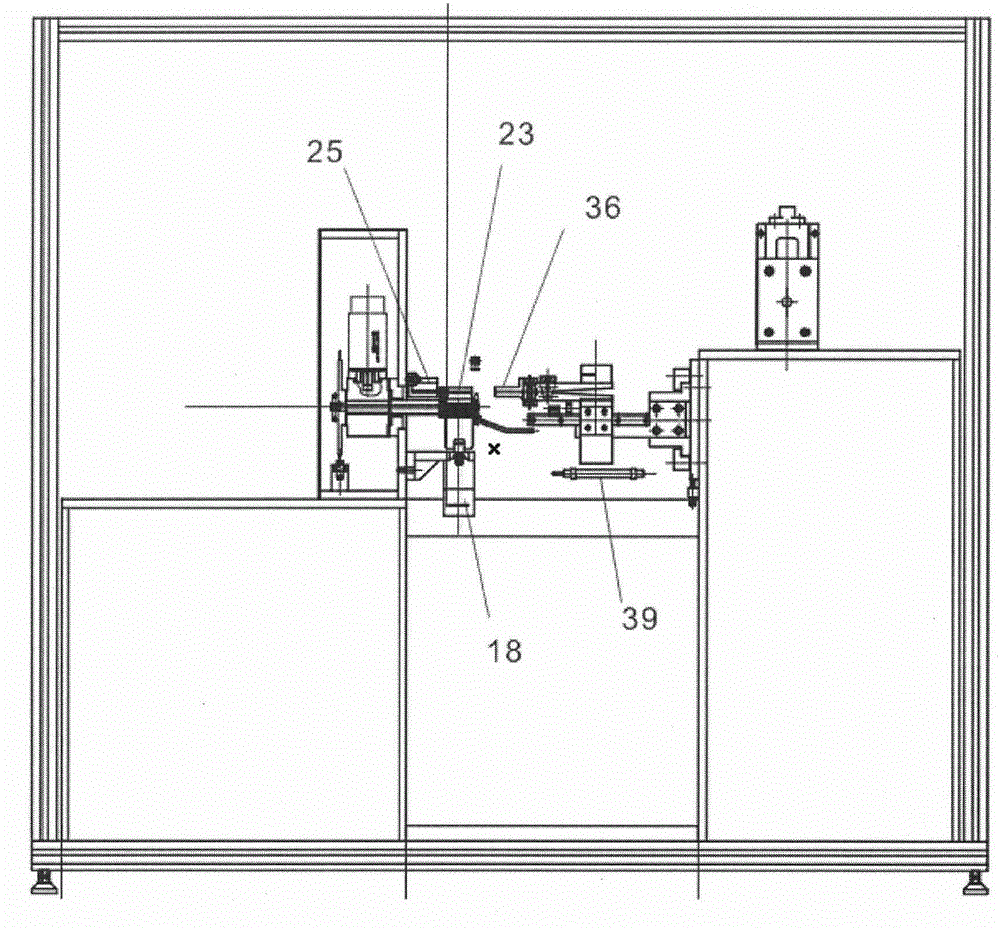

[0026] like Figure 1 to Figure 3 As shown, the fully automatic stainless steel ring welding machine provided by the present invention includes a body 1, a steel belt transmission processing device and a steel belt laser welding device fixed on both sides of the body 1. The material tray 2, the steel belt primary drive, the material storage device, the steel belt secondary drive, the steel belt guide device, the steel belt coiling device and the material cutting device fixed on the inside of the body 1, the above-mentioned steel belt primary drive and steel belt two The secondary drive is set up and down by the rubber wheel 3 and the steel wheel 4, and a pull rod 5 is fixed on the outside of the two, and the adjustment wrench 6 is fixed on the pull rod 5. The steel belt is fixed close to the material tray 2 for the primary drive, and is provided by the storage drive motor. Power, the secondary drive of the steel belt is driven by a servo motor. The above-mentioned storage devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com