Fast dehydration system for iron ore concentrate powder

An iron ore concentrate powder and rapid dehydration technology, applied in filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of high moisture content of the final product, large investment in dehydration system, low production efficiency, etc. Small size, lower investment and production costs, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

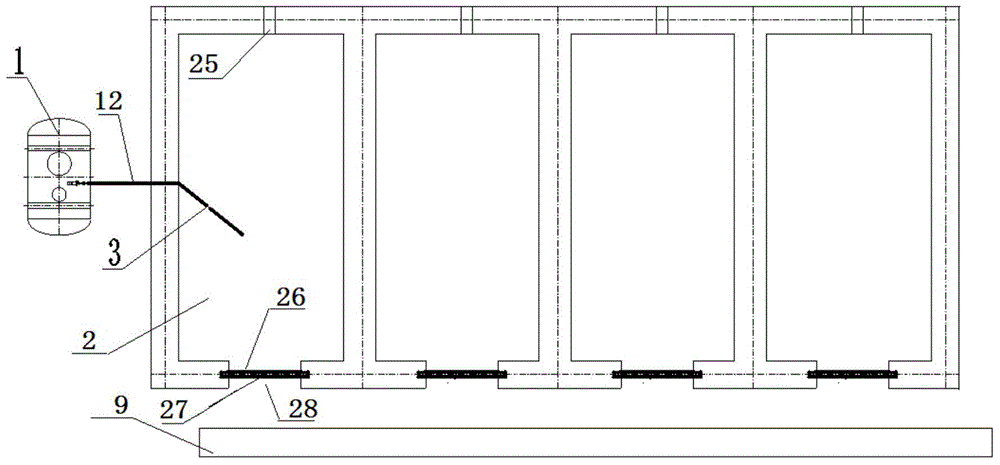

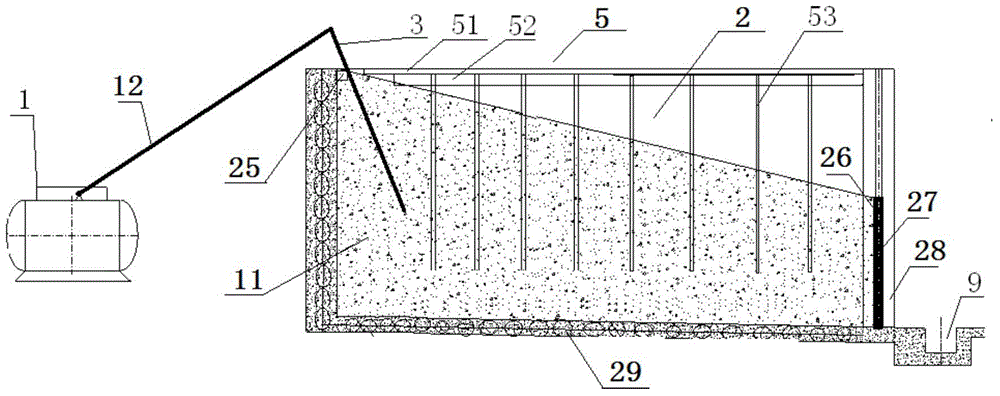

[0038] A kind of quick dehydration system of iron concentrate powder of the present embodiment, as figure 1 As shown, it includes a sedimentation tank 2, a filter device 6, a high-pressure air blowing device 1, an air blowing pipe 3 and a solar heating device 5, wherein: the sedimentation tank 2 includes a pulp inlet 25, a pulp spacer 27, and a sedimentation tank discharge port 28 and the slope bottom 29 of the sedimentation tank; the slurry inlet 25 is opened on the left side of the top of the sedimentation tank 2, and the ore discharge port 28 of the sedimentation tank is opened at the bottom of the right side wall of the sedimentation tank 2; the slurry spacer 27 is arranged in the sedimentation tank The inner side of the ore discharge port 28; the bottom of the sedimentation tank 2 is the slope bottom 29 of the sedimentation tank with a left high and a right low inclination angle, and the inclination slope is 1%; The powder 11 is blown; the solar heating device 5 is arrang...

Embodiment 2

[0041] A kind of rapid dehydration system of iron ore powder of the present embodiment, its basic structure is the same as embodiment 1, and the improvement is: as figure 1 As shown, there are 4 settling tanks 2, which are connected side by side to form an integrated structure; the filter device 6 is a pulp spacer 27 with mesh; figure 2 As shown, the solar heating device 5 includes a heat collecting layer 51, a heat storage layer 52 and a heat conducting rod 53; the heat collecting layer 51 is outside and the heat storing layer 52 is arranged inside, and the fixed connection is an integrated structure; the fixing of the heat conducting rod 53 The end is vertically inserted into the heat storage layer 52 and fixedly connected with the heat collection layer 51, and the free end is vertically inserted into the iron concentrate powder 11 inside the sedimentation tank 2. The heat collection layer 51 is a flat solar heat collector; the heat conduction rod 53 is a telescopic There a...

Embodiment 3

[0045] A fast dehydration system for iron ore powder in this embodiment has the same basic structure as that in Embodiment 2, the difference is that an electric heater is added in the surrounding wall of the pool, and the inner wall of the sedimentation tank 2 is made of metal to increase heat conduction As a result, the outer wall is made of concrete, and the heat loss is slow, avoiding unnecessary waste of heat. The inclination slope of the slope bottom 29 of the sedimentation tank is 3%.

[0046] In the rapid dehydration system of iron ore powder in this embodiment, an electric heater is added to the surrounding wall of the pool. Although the initial investment is increased, the production cost can be effectively reduced, and heating can also be performed without solar energy storage. The specific use It is also possible not to use electric heaters on the two walls of the sedimentation tank to reduce the total loading of the entire system, but the production efficiency will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com