A method for rapid dehydration of iron concentrate powder in a sedimentation tank

A technology for rapid dehydration of iron concentrate powder, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of high moisture content of the final product, large investment in dehydration system, low production efficiency, etc. Small size, lower investment and production costs, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for quick dehydration of iron concentrate powder in a settling tank of the present embodiment, the steps are:

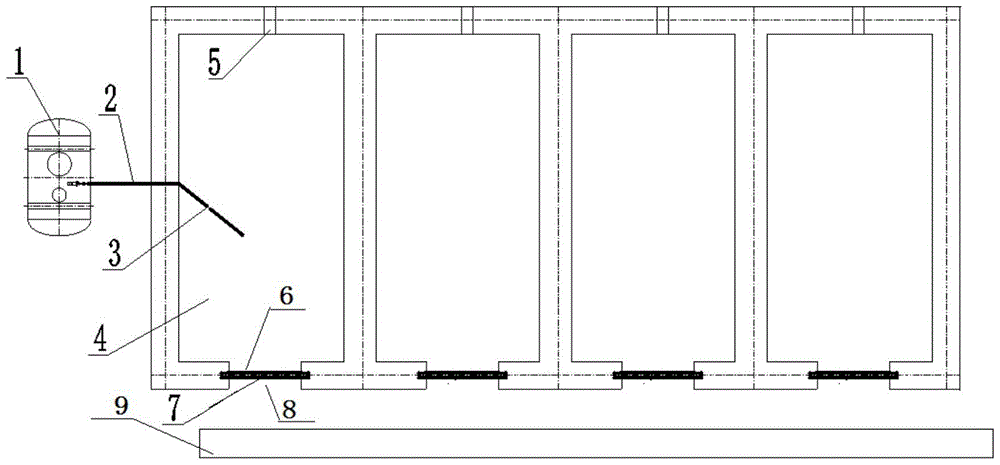

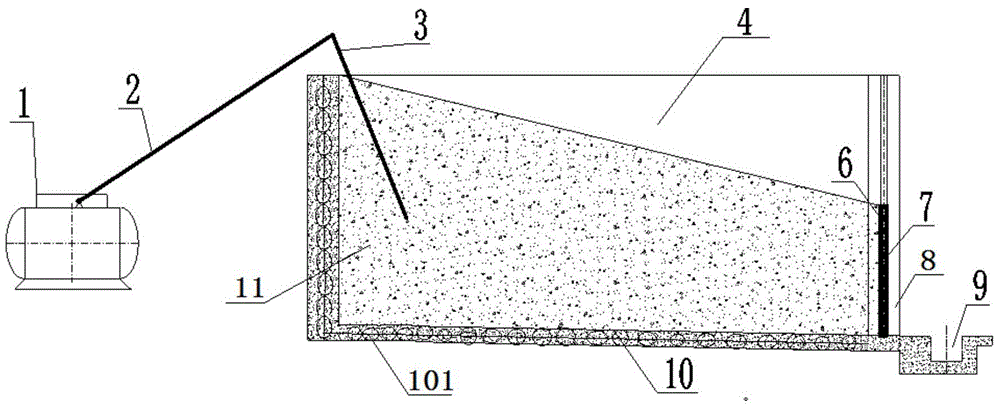

[0045] A. Set up 4 iron concentrate powder quick dehydration devices side by side, such as figure 1 As shown, they are device 1, device 2, device 3 and device 4 respectively; the iron concentrate powder quick dehydration device is as figure 2 As shown, it includes air compressor 1, blowing pipe 3, sedimentation tank 4, pulp inlet 5, filter mechanism, sedimentation tank discharge port 8 and overflow drainage ditch 9, wherein: sedimentation tank 4 is a rectangular tank body, the specification The size is 9.0m*4.5m*4.2m, and the material is concrete. The slurry inlet 5 is opened on one side of the top of the sedimentation tank 4, and the discharge port 8 of the sedimentation tank is opened on the bottom of the other side wall of the sedimentation tank 4. The sedimentation tank The specification of the ore discharge port 8 is 2.0m*2.0m; the filter mecha...

Embodiment 2

[0054] A method for rapid dehydration of iron concentrate powder in a sedimentation tank in this embodiment, its basic steps are the same as in Example 1, and the improvement is that the applied iron concentrate powder 11 has an iron grade of 68% and a product particle size greater than 200 mesh accounted for less than 80%. In step C, the filtering mechanism is a slurry spacer plate 7 with mesh. In step E, an electric heater is set in the side wall of the sedimentation tank 4 and the slope bottom 10 of the sedimentation tank, and the air blowing pipe 3 is a galvanized steel pipe; the inclination gradient of the slope bottom 10 of the sedimentation tank is 2%; 3 air blowing pipes are 4, connected in parallel Finally, it is connected with the exhaust hose 2 of the air compressor, and blows air evenly to 11 pairs of iron concentrate powders 11 inside the iron concentrate powder from four directions of the sedimentation tank 4 at the same time, the blowing pressure is 0.9MPa, and ...

Embodiment 3

[0057] The method for rapid dehydration of iron concentrate powder in the sedimentation tank in this embodiment has the same basic steps as in Embodiment 2, except that in step E, a solar heating mechanism is installed on the top of the sedimentation tank 4 . In step B, the inclination slope of the slope bottom 10 of the sedimentation tank is 3%. In step D, let stand for 40 minutes.

[0058] In the method for quick dehydration of iron concentrate powder in a sedimentation tank of this embodiment, a solar heating mechanism is arranged on the top of the sedimentation tank 4. Although the initial investment is increased, the production cost can be effectively reduced, and the heating mechanism on the walls around the sedimentation tank can also be omitted. The total load of the whole system is reduced, but the production efficiency will not be reduced, and the versatility of the whole system is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com