Comprehensive shock absorbing and noise reducing device of motor

An all-round, noise-reducing technology, applied in the direction of electromechanical devices, installation of electrical equipment, electrical components, etc., can solve problems such as sealing ring suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] As mentioned in the background technology, the existing seal ring is used for shock absorption and noise reduction at the air inlet of the motor. The seal ring is made of soft material, such as foam material, silica gel, etc., and its side wall is provided with a circle structure so that the motor can move within a certain space.

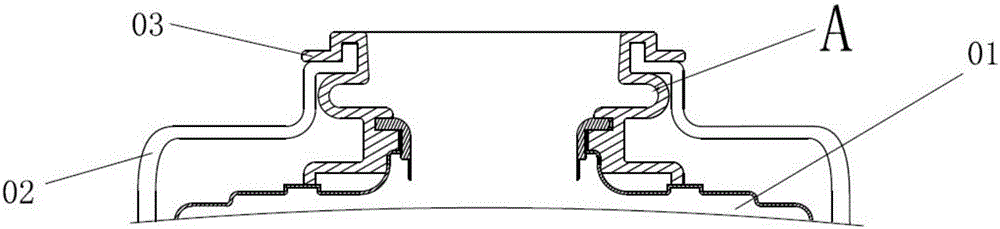

[0034] Please refer to figure 1 , figure 1 It is the motor head in the prior art. The motor as shown in the figure includes motor body 01, motor cover 02 and seal ring 03. The middle part of seal ring 03 is provided with a U-shaped structure to realize shock absorption for the motor body 01 in the direction of the motor shaft, so that the motor body 01 is allowed to move on the motor shaft. swing in the direction in which it is located. However, when the motor main body 01 swings left and right, due to figure 1 The sealing ring 03 at A is in close contact with the motor cover 02, so the shock absorption in the normal direction of the moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com