Damping and noise reduction structure of electric scroll compressor

A scroll compressor and noise reduction technology, applied in the field of scroll compressors, can solve the problems of large space, occupation, increased cost, etc., and achieve the effects of noise reduction, reliable fixation, good shock absorption and noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

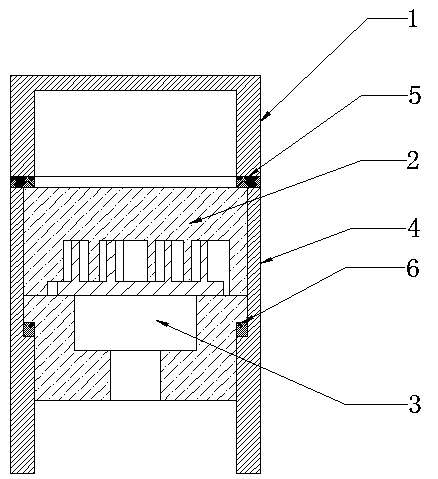

[0012] as attached figure 1 As shown, a shock-absorbing and noise-reducing structure of an electric scroll compressor includes an end cover 1, a fixed scroll 2, a support plate 3, and a casing 4. The casing 4 is in a cylindrical structure, and the The top of the casing 4 is provided with an end cover 1, the inside of the casing 4 is provided with a recessed structure, a support plate 3 is installed at the bottom of the recessed structure of the casing 4, and a static scroll is arranged on the top of the support plate 3 2. A rubber gasket A5 is arranged between the end cover 1 and the casing 4, and a rubber gasket B6 is arranged at the contact part between the support plate 3 and the bottom of the concave structure of the casing 4.

[0013] The rubber gasket A5 and the rubber gasket B6 are bonded to the casing 4 by glue or glue points.

[0014] The upper and lower surfaces of the rubber gasket A5 and the rubber gasket B6 are all provided with raised floating points.

[0015] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com