Magnetic latching relay with asymmetric magnetic circuit

A magnetic latching relay, asymmetric technology, applied in electromagnetic relays, electromagnetic relay details, relays, etc., can solve the problems of complex magnetic circuit structure of relays, unfavorable miniaturization design, low performance indicators of relays against harsh environments, and achieve structural Symmetrical, simplified design, convenient suction and reaction force matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

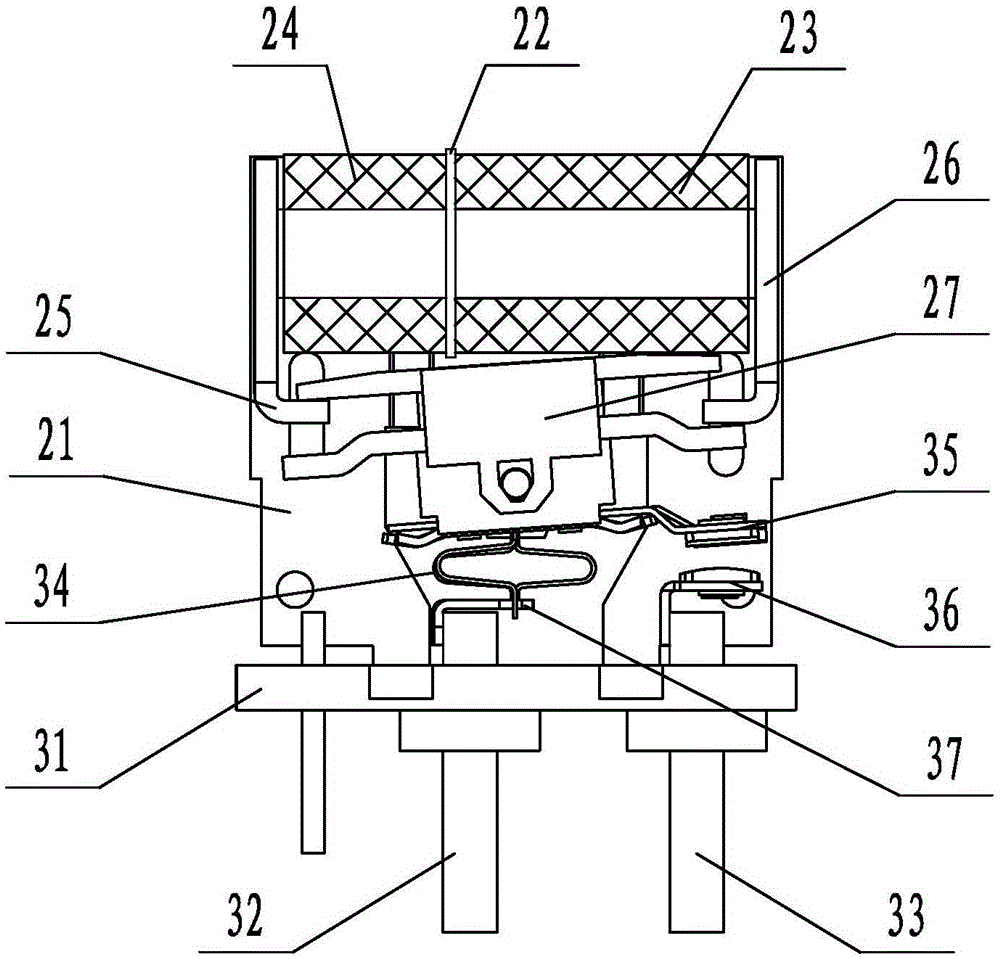

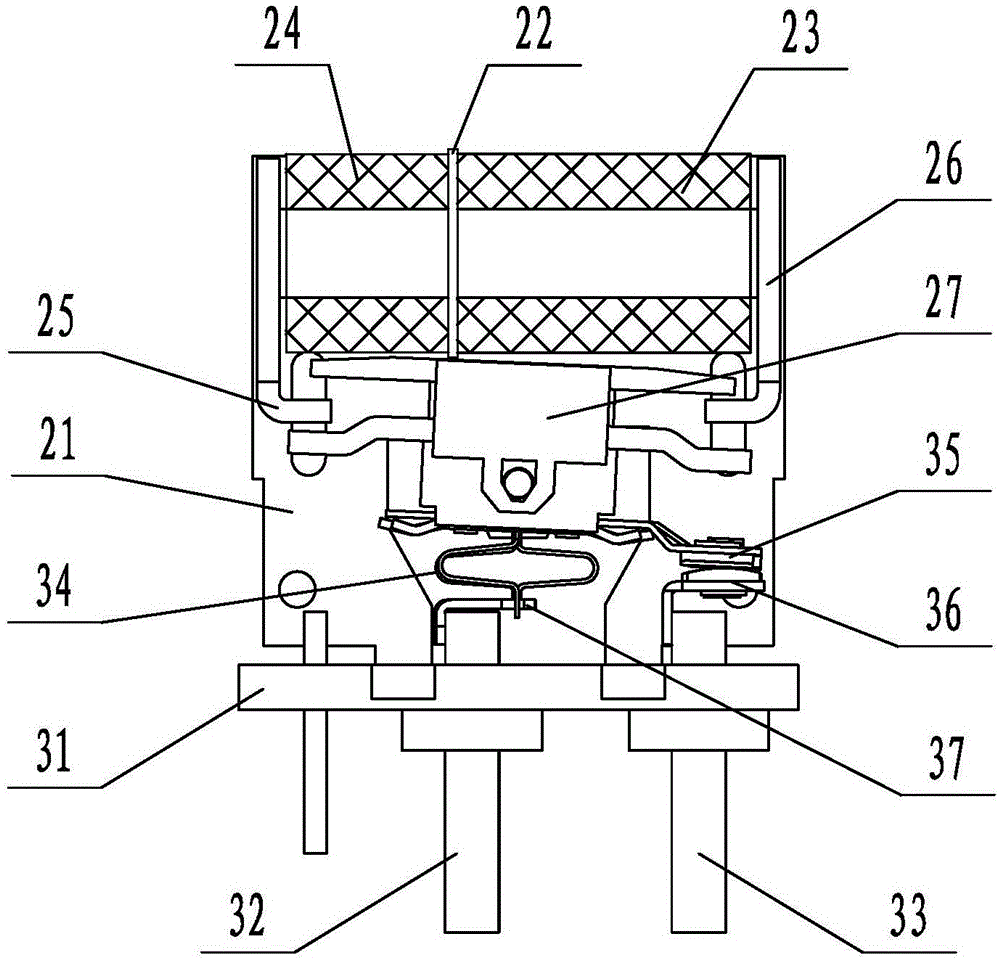

[0027] A magnetic latching relay with an asymmetrical magnetic circuit, such as figure 1 As shown, it is mainly composed of a sealed casing 1, an electromagnetic system 2 and a contact system 3. The electromagnetic system 2 is crimped with the grooves on the base 31 group in the contact system 3 through its two side plates 21 and then connected together by resistance welding to form the whole relay. The entire relay is pressed into the sealed casing 1, and then laser welding is performed on the gap where the two are pressed, so that the entire relay can be welded and sealed to form a magnetic latching relay.

[0028] The electromagnetic system 2 includes a bobbin 22 , a self-holding coil 23 , a return coil 24 , a self-holding yoke 25 , a return yoke 26 and an armature 27 . The coil bobbin 22 is in the shape of a barrel, and is placed horizontally on the upper part of the inner cavity of the sealed casing 1 . The return coil 24 is wound on one side of the outer wall of the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com