A Rapid Joint Measurement Method of Copper, Zinc and Iron Content in Gold Mud

A technology of copper, zinc and iron content, which is used in material analysis by observing the effect on chemical indicators, and analysis by chemical reaction of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

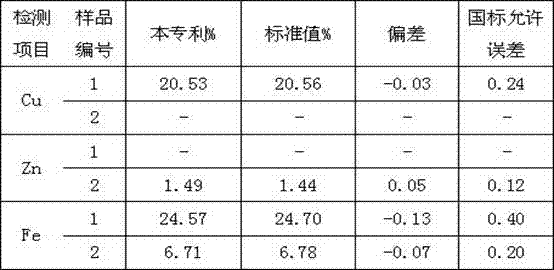

Image

Examples

Embodiment Construction

[0088] The present invention will be further described below in combination with specific embodiments.

[0089] Main reagents:

[0090] Reagents and standard solutions, etc., which are the same as the requirements in GB / T 7739.4, 6, and 7 will not be described in detail, and the differences will be specifically explained in the specification of the present invention.

[0091] Sample pretreatment:

[0092] Put the prepared gold mud sample (hereinafter referred to as the sample) into a constant temperature drying oven, set the temperature at 105-110°C, and after drying to a constant weight, take it out and put it in a desiccator to cool to room temperature for later use. The main purpose of this process is to remove the moisture in the sample to ensure the accuracy of the capacity analysis results.

[0093] Analysis steps:

[0094] 1. Sample dissolution: Accurately weigh 0.2000g ~ 1.0000g sample into a 300mL beaker, moisten it with a little water, add 15mL nitric acid (1+1), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com